Economic Development Administration Awards Georgia Tech $65 Million for AI Manufacturing Project

Sep 02, 2022 — Atlanta, GA

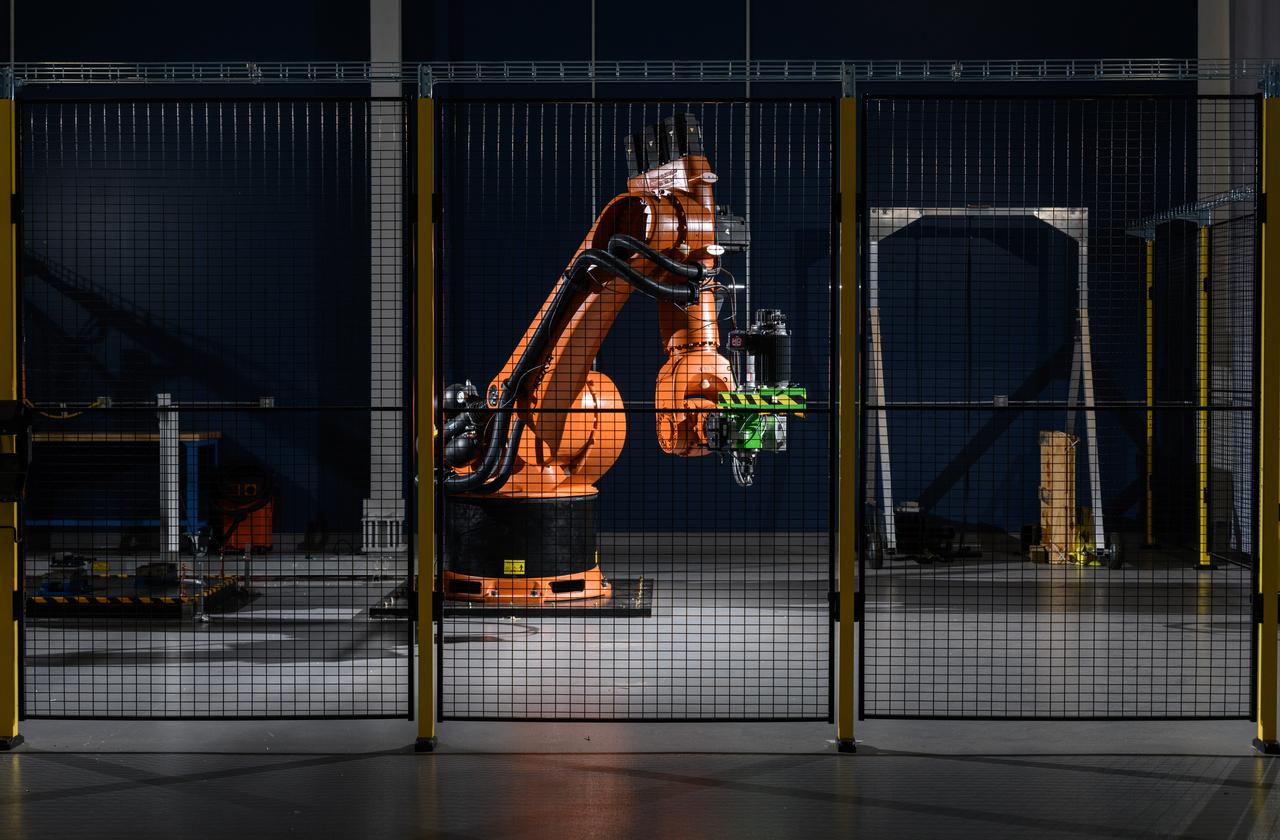

Georgia Tech is developing plans with partners across the state to build the Georgia Artificial Intelligence Manufacturing Corridor (GA-AIM). This project aims to build and bolster Georgia's economy by filling existing technology gaps, building a technological opportunity framework that includes underrepresented communities and rural Georgia counties, and better securing the state’s manufacturing infrastructure.

The Georgia Institute of Technology has been awarded a $65 million grant from the U.S. Department of Commerce’s Economic Development Administration (EDA) to support a statewide initiative that combines artificial intelligence and manufacturing innovations with transformational workforce and outreach programs. The grant will increase job and wage opportunities in distressed and rural communities, as well as among historically underrepresented and underserved groups.

The Georgia Artificial Intelligence Manufacturing Technology Corridor (GA-AIM) effort is one of 21 winning projects the White House announced today under the Biden administration’s $1 billion Build Back Better Regional Challenge. The award follows a $500,000 Phase 1 feasibility grant the project received in 2021.

“Georgia Tech is honored to lead this vision of collaborative innovation and economic development across all regions of our state,” said Georgia Tech President Ángel Cabrera. “This award underscores the Institute's commitment to leverage our resources and expertise to address great challenges, serve our state and nation, and amplify our impact on the world.”

The selected awardees represent projects in 24 states with grant amounts ranging from $25 million to $65 million.

“As we invest and grow critical industries in the U.S., we want to create industry hubs in diverse communities across the country,” U.S. Secretary of Commerce Gina Raimondo said in a statement. “These grants will provide critical and historic funding directly to community coalitions to invest in new infrastructure, research and development, and workforce development programs while creating good-paying jobs, supporting workers, and prioritizing equity.”

The GA-AIM project is led by Aaron Stebner, associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering; Donna Ennis, director of Diversity Engagement and Program Development in Georgia Tech’s Enterprise Innovation Institute and also director of its Georgia MBDA Business Center; and Thomas R. Kurfess, executive director of the Georgia Tech Manufacturing Institute.

“The ability to integrate our discoveries and innovations here at the AI Manufacturing Pilot Facility with novel workforce programs and transformative outreach experiences is a once-in-a-lifetime opportunity to do something greater in ways that increase opportunity and prosperity for all Georgians,” Stebner said. “Through an equitable AI manufacturing innovation focus, the assembled coalition of partners and stakeholders across the state will build a more prosperous and resilient Georgia and set a nation-leading example.”

The AI Manufacturing Pilot Facility, which will allow for government and industry pilot trials, cybersecurity games, and workforce training for AI manufacturing technologies, is just one component of Georgia Tech’s support for the project.

Two of Georgia Tech’s commercialization programs — VentureLab and I-Corps South — will create a center for the commercialization of AI manufacturing technologies into local and regional startups through training built on the National Science Foundation’s I-Corps curriculum.

The Enterprise Innovation Institute, Georgia Tech’s economic development arm, will engage in focused outreach and technical assistance to small- and mid-sized manufacturers and minority business enterprises through its Georgia Manufacturing Extension Partnership (GaMEP) and Georgia MBDA Business Center programs. Other Enterprise Innovation Institute programs include the Economic Development Lab, the Partnership for Inclusive Innovation, and ATDC, which will focus on outreach and engagement in distressed and underserved parts of the state, create workforce development programs, implementation strategies, and attract outside investment.

“The work that we will accomplish with our broad spectrum of partners in this new endeavor will leverage the latest technology in artificial intelligence to grow and strengthen our workforce ensuring that the growing manufacturing sector in Georgia has the skilled workforce that it requires for today’s as well as tomorrow’s needs,” Kurfess said. “At the same the high paying and secure jobs will be going to a very diverse population base from across the state, providing an equitable robust future for all citizens of Georgia.”

Georgia Tech’s Supply Chain & Logistics Institute will study the impact of automation technologies, build automation solutions tailored for rural manufacturers, and create programs that lower the barrier for rural manufacturers’ access to use the AI Manufacturing Pilot Facility.

In addition, Georgia Tech’s Ethics, Technology, and Human Interaction Center (ETHICx), led by faculty in the Ivan Allen College of Liberal Arts, will help integrate considerations of equity, fairness, accountability, and transparency into GA-AIM and promote the responsible and ethical use of AI-manufacturing technologies.

Finally, Georgia Tech’s K-12 InVenture Prize and Center for Education Integrating Science, Mathematics and Computing programs will expand their emphasis to rural and underserved areas of the state by piloting a rural regional event with a region-specific prize. They will also create supplemental lessons centered on AI and data science that will be part of a K-12 InVenture Prize curriculum website.

“We are excited to be a part of this collaborative effort to catalyze research and innovation in AI and manufacturing across the state of Georgia,” said Chaouki T. Abdallah, executive vice president for Research at Georgia Tech. “This project aligns with our goals to expand economic opportunity in our state's underserved communities, and to serve as a collaborative hub for interdisciplinary research that advances technology and improves people’s lives.”

Georgia Tech is working with a coalition of statewide partners to create a foundation that supports existing business growth and new business ventures across the state especially in underserved communities and rural Georgia.

“All across the state of Georgia, our programs in the Enterprise Innovation Institute work hard to unlock potential and foster economic opportunity for all, particularly in underserved and marginalized communities,” said David Bridges, vice president of the Enterprise Innovation Institute, and co-author of the grant proposal with Stebner. “This project leverages what we and our partners each do best to help achieve our broader Georgia AIM goals.”

Tech’s partners include the:

· Georgia Department of Community Affairs

· Houston County Development Authority

· KITTLabs

· Russell Innovation Center for Entrepreneurs

· Robins Air Force Base 21st Century Partnership

· Southwest Georgia Regional Commission

· Technology Association of Georgia Education Collaborative

· Technical College System of Georgia

“What's really special about this effort is that it's centered on a wholistic approach with innovation, not just one piece of AI or manufacturing,” Ennis said. “We're working collectively statewide to transform and propel forward our industry, communities, and most importantly, our people.”

That collective approach is critical to GA-AIM’s success, said Houston County Development Authority Executive Director Angie Gheesling.

“The Development Authority and the 21st Century Partnership lead the Middle Georgia Innovation Project, which includes 11 counties in the Middle Georgia region, a diverse landscape of communities from rural to urban,” she said. “This award further facilitates the continuation of several years of collaboration between local leadership, our universities, private industry, and Robins Air Force Base to position ourselves as a Software Center of Excellence. We are grateful to Georgia Tech for the opportunity to partner and contribute to the overall future success of GA-AIM.”

Burunda Prince, chief operating officer of the Russell Innovation Center for Entrepreneurs, echoed those sentiments, saying its reach is exponentially amplified through the GA-AIM partnership.

The Center will create a mobile, 5,000-square-foot LaunchPad AI Innovation Studio to provide prototyping and proof-of-concept development of physical products. Black entrepreneurs in rural and urban Georgia will have access to equipment, training, and mentoring, and LaunchPad AI will also be open to AI InVenture teams from Atlanta’s urban K-12 schools.

“As part of the Build Back Better grant, the Russell Innovation Center for Entrepreneurs will help Black businesses leverage the benefits of artificial intelligence to provide better data and insights that will build stronger companies and drive greater wealth generation,” Prince said. “What makes this opportunity unique is the cross collaboration of partners which will engage and empower communities across Georgia through access to technologies that often are inaccessible.”

Equally as important is the education component and the ability for it to be a bridge to new skills and opportunities for Georgia workers, said Technical College System of Georgia Commissioner Greg Dozier.

“The funding for the project will equip four TCSG colleges with state-of-the-art manufacturing studios that will showcase the clean, safe state of modern manufacturing,” Dozier said. “Automation in manufacturing creates a demand for more skilled jobs, giving TCSG the charge to strengthen the workforce pipeline by training Georgians in these exciting, new technologies. The Georgia AIM project provides the funding to meet these opportunities head on.”

###

About the U.S. Economic Development Administration

The mission of the U.S. Economic Development Administration (EDA) is to lead the federal economic development agenda by promoting competitiveness and preparing the nation's regions for growth and success in the worldwide economy. An agency within the U.S. Department of Commerce, EDA makes investments in economically distressed communities to create jobs for U.S. workers, promote American innovation, and accelerate long-term sustainable economic growth.

About the Georgia Institute of Technology

The Georgia Institute of Technology, or Georgia Tech, is a top 10 public research university developing leaders who advance technology and improve the human condition. The Institute offers business, computing, design, engineering, liberal arts, and sciences degrees. Its nearly 44,000 students representing 50 states and 149 countries, study at the main campus in Atlanta, at campuses in France and China, and through distance and online learning. As a leading technological university, Georgia Tech is an engine of economic development for Georgia, the Southeast, and the nation, conducting more than $1 billion in research annually for government, industry, and society.

Writer: Péralte C. Paul I peralte.paul@comm.gatech.edu I 404.316.1210

Media contact: Ayana Isles | aisles3@gatech.edu | 404.660.2927

GLUE Webinar: General Lectures Uniting Everyone

This webinar is offered virtually via Zoom. Please click here to register.

"Bringing Engineers & Clinicians Together To Explore Microchip Applications In Healthcare"

Farrokh Ayazi, Ph.D.

Regents Entrepreneur & Ken Byers Professor in Microsystems

School of Electrical and Computer Engineering

Georgia Tech

Lim Becomes First ECE Faculty Member to Join DARPA as Program Manager

Aug 31, 2022 — Atlanta, GA

ECE Professor Sung-Kyu Lim

This August, Georgia Tech professor Sung Kyu Lim joined the Defense Advanced Research Projects Agency (DARPA) as a program manager in the Microsystems Technology Office (MTO). Lim, the Motorola Solutions Foundation Professor in School of Electrical and Computer Engineering (ECE), is the first Georgia Tech ECE researcher to be recruited and serve as a DARPA program manager while teaching at Georgia Tech.

As a prominent researcher in very-large-scale integration (VLSI) systems and design, Lim’s first program at DARPA, dubbed the “3D-EDA (3D Electronic Design Automation) Program,” will develop heterogeneous 3D integrated circuits (IC) design and simulation software to automatically co-optimize the underlying device, circuit, and architecture. The program will use 3D-EDA tools to demonstrate 10x shorter design turnaround time and 10x energy-efficiency improvement.

“We are very proud of Sung Kyu’s appointment to DARPA’s Microsystems Technology Office,” said Arijit Raychowdhury, ECE’s Steve W. Chaddick School Chair. “This is an important recognition of Sung Kyu’s standing in the VLSI field, and also shows how Georgia Tech ECE researchers are leading, on the national level, in developing advanced defense research projects.”

The core mission of DARPA’s MTO is to develop high-performance intelligent microsystems and next-generation components to ensure U.S. dominance in the areas of Command, Control, Communications, Computing, Intelligence, Surveillance, and Reconnaissance (C4ISR), Electronic Warfare (EW), and Directed Energy (DE).

According to DARPA, the office’s work in applying advanced capabilities in areas such as wide-band gap materials, phased array radars, high-energy lasers, complementary metal-oxide-semiconductor (CMOS) circuits, and infrared imaging has helped the U.S. establish and maintain technological superiority for more than two decades.

Lim’s DARPA assignment is supported by the U.S. Department of Defense’s (DoD) Intergovernmental Personnel Act (IPA), which allows for the temporary assignment of skilled personnel between the Federal Government and state and local governments, colleges and universities, Indian tribal governments, federally funded research and development centers, and other eligible organizations.

He will serve for four years at the agency in Washington D.C. before returning to Georgia Tech. Lim’s GTCAD (Georgia Tech Computer-Aided Design) Lab will remain open during his 4-year DARPA term.

Dan Watson

dwatson@ece.gatech.edu

2022-2023 Institute for Bioengineering and Bioscience Distinguished Lecture

"Designer Nanocarriers for Cancer Therapy"

Paula T. Hammond, Ph.D.

Institute Professor and Department Head of Chemical Engineering

Koch Institute of Integrative Cancer Research

Massachusetts Institute of Technology

Exponential Electronics Proposers Mini-Workshop

Institute for Electronics and Nanotechnology Exponential Electronics (IEN-EX) Proposers Mini-Workshop

Potential IEN-EXproposers are encouraged to attend the mini-workshop on September 15, 2022, from 11:00 a.m. - 1:00 p.m. in Marcus 1117/1118. Michael Filler, IEN Associate Director for Research Programs, will explain the motivation and goals of the IEN-EX program, provide examples of 1000x ideas, as well as offer attendees time to discuss potential 1000x ideas and begin team building.

Tech Faculty Tapped for Regents' Awards

Aug 11, 2022 — Atlanta, GA

Koan at Georgia Tech

Along with the Georgia Tech faculty tapped and reappointed as Regents’ Professors and Researchers at the Aug. 9 University System of Georgia (USG) Board of Regents meeting were five Georgia Tech professors named to the new distinction of Regents’ Entrepreneur.

Georgia Tech faculty named as the first Regents' Entrepreneurs in the USG include Farrokh Ayazi, Ken Byers Professor in Microsystems, School of Electrical and Computer Engineering; Kirk Bowman, professor, Sam Nunn School of International Affairs; Andrei Fedorov, Neely Chair and professor, Woodruff School of Mechanical Engineering and the Petit Institute for Bioengineering and Biosciences; Mark Prausnitz, Regents’ Professor, J. Erskine Love Jr. Chair, School of Chemical and Biomolecular Engineering; and Gleb Yushin, professor, School of Materials Science and Engineering.

Regents’ Professor First-Time Appointments

The Board of Regents approved the title of Regents’ Professor to Facundo Fernández, professor and Vasser Woolley Foundation Chair in Bioanalytical Chemistry, School of Chemistry and Biochemistry; Willie Pearson, professor of sociology, School of History and Sociology; Krishnendu Roy, professor, Robert A. Milton Endowed Chair, NSF Engineering Research Center for Cell Manufacturing Technologies, Coulter Department of Biomedical Engineering; and Beril Toktay, professor of Operations Management and Brady Family Chairholder, Scheller College of Business.

Regents’ Researcher First-Time Appointments

Those named as Regents’ Researchers include Stephen Balakirsky, principal research scientist, Georgia Tech Research Institute (GTRI); Anton Bryksin, principal research scientist, Petit Institute for Bioengineering and Bioscience; Walter Bradley Fain, principal research scientist, School of Public Policy; and Anita Pavadore, principal research engineer, GTRI.

First-Time Reappointments

Receiving a first-time reappointment as Regents’ Professor was Surya Kalidindi, Regents’ Professor, Rae S. and Frank H. Neely Chair, Woodruff School of Mechanical Engineering. Receiving a first-time reappointment as Regents’ Researcher was Margaret Loper, principal research scientist, GTRI.

Other Reappointments

Regents’ Professor and Researcher designations only require Institute approval for second-time reappointments. Second-time Regents’ Professor appointments at Georgia Tech include Sy Goodman, Regents’ Professor and professor of International Affairs and Computing, Sam Nunn School of International Affairs; Nicholas Hud, Regents’ Professor, School of Chemistry and Biochemistry; and Vladimir Tsukruk, Regents’ Professor, School of Materials Science and Engineering. Receiving a second-time Regents’ Researcher reappointment was Alexa Harter, director of the Cybersecurity, Information Protection, and Hardware Evaluation Research Laboratory at GTRI.

New Recognition for Entrepreneurship and Innovation

The board approved the Regents’ Entrepreneur designation in their February 2022 meeting to recognize and support faculty entrepreneurship and innovation. The Regents’ Entrepreneur designation may be granted by the Board of Regents to an outstanding full-time tenured faculty member who has an established reputation as a successful innovator and who has taken their research into a commercial setting. The Regents’ Entrepreneur designation is bestowed by the board only upon the unanimous recommendation of the USG institution president, the chief academic officer, and the chancellor, and upon the approval of the Committee on Academic Affairs.

Farrokh Ayazi

Farrokh Ayazi is director of the Georgia Tech Analog Consortium. His main research interest is in integrated micro and nano electromechanical systems and integrated microsystem design. He is the founder and chief technology officer of Qualtré, which was acquired by Panasonic in 2016. He is currently leading StethX Microsystems, an ATDC company, in commercializing advanced wearable sensors for cardiopulmonary applications.

Kirk Bowman

Kirk Bowman is the Rise Up & Care term chair in Global Development and Identity. In 2014, Bowman founded Rise Up & Care, a nonprofit corporation that employs an innovative model of international community development, combining global development research; high-level performance organizations in the Global South to transform youth; powerful documentary films by top local directors; and children's books illustrated by local street artists. He directs a Georgia Tech Vertically Integrated Project on Global Social Entrepreneurship with 18 undergraduate students.

Andrei G. Fedorov

Andrei G. Fedorov’s research covers atomic scale nanomanufacturing; distributed power generation with carbon dioxide management; instrumentation for biomedical research; and thermal management of electronics and medicine. With his students and collaborators, Fedorov started several technology companies to commercialize his inventions in the space of gene/drug delivery; biomarker discovery and quality control in cell therapy manufacturing; and thermal management of high-power generation devices.

Mark Prausnitz

Mark Prausnitz has co-founded seven companies that have together raised more than $350 million for commercialization of microneedle technologies developed in his lab at Georgia Tech. Three of the companies have products for sale, including an FDA-approved treatment of ocular inflammation. His technologies have been studied in more than 20 human clinical trials. He has almost 80 issued or pending U.S. patents, with additional international filings. Prausnitz has published more than 300 journal articles and supervised 50 Ph.D. students among a total of almost 350 graduate, postdoctoral, or undergraduate researchers in his lab.

Gleb Yushin

Gleb Yushin is a pioneer and globally recognized leader in advanced materials for next-generation Li-ion batteries. He is member of the National Academy of Inventors and fellow of three international professional societies. He has been awarded more than 200 patents, while also being one of the most cited Georgia Tech professors since 2019. He co-founded the most economically successful Georgia Tech startup Sila Nanotechnologies ($3.3B valuation). Yushin has served as a founding faculty advisor for the Entrepreneurs Club at Tech and as an advisor to the Georgia Tech startup CellFE.

Regents’ Professorships and Regents’ Researcher titles may be granted for a period of three years by the Board of Regents to outstanding faculty members of Georgia Tech, Augusta University, Georgia State University, the University of Georgia, and, in special circumstances, other USG institutions.

Dawn Baunach, Associate Vice Provost for Faculty

New Chip Could Make Treating Metastatic Cancer Easier and Faster

Aug 11, 2022 — Atlanta, GA

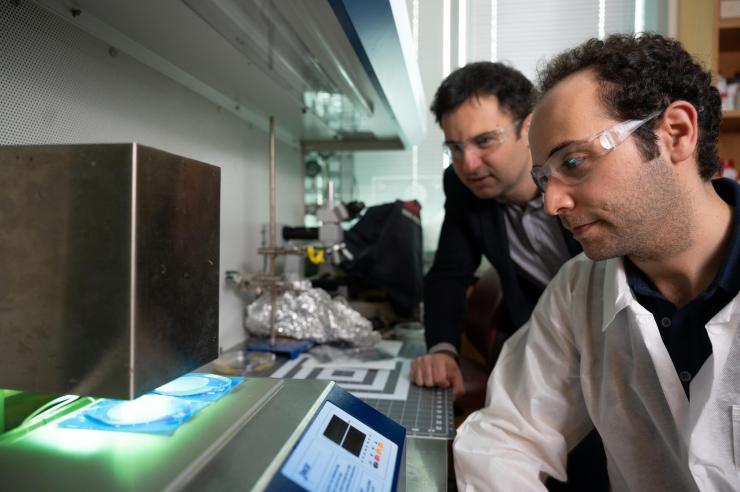

Fabrication of the microchip. The device is fabricated by injecting a polymer into a micro fabricated mold and the polymer is cured under ultraviolet light to produce low-cost, single-use devices.

Cancer spreads via circulating tumor cells (CTCs) that travel through the blood to other organs, and they are nearly impossible to track. Now, researchers at the Georgia Institute of Technology have found a detection method that could revolutionize cancer treatment by showing how cancers metastasize and what stage they are. This could lead to earlier and more targeted treatment, beginning with a simple blood test.

When a tumor starts metastasizing, it sheds its cell into the blood. An individual cell often doesn’t survive the bloodstream on its own, but clusters of cells are much more robust and can travel to other organs, effectively pushing the cancer to a metastatic state.

CTCs have proven difficult to study, let alone treat. Blood contains billions of cells per milliliter, and only a handful of those cells would be CTCs in a patient with metastatic cancer. Such intense filtration has been inaccessible using conventional lab methods. Most traditional filtration is too aggressive and would break the cluster back into single cells and ruin the ability to study the effect of a cluster.

“That’s what got engineers like me interested in this because we are really good at creating sensors, or small devices that actually do sensitive analysis,” said School of Electrical and Computer Engineering Associate Professor Fatih Sarioglu. “We started developing technologies to catch these precious cells to help manage cancer better.”

Sarioglu presented the research in “High Throughput, Label-free Isolation of Circulating Tumor Cell Clusters in Meshed Microwells,” recently published in Nature Communications.

Creating the Cluster-Well

Sarioglu’s lab invented a new type of chip called the Cluster-Well, combining the precision of microfluidic chips with the efficiency of membrane filtration to find CTC clusters. Using micron-sized features, microfluidic chips can precisely locate each cell in a blood sample and determine if it’s cancerous.

“Microfluidic chips give you more control as a designer to actually ask whatever question that you want to ask those cells,” Sarioglu said. “It increases the precision and sensitivity, which is what you need for an application like this because you want to find that single cell out of many blood cells.”

To rapidly process a clinically relevant volume of blood, the researchers relied on membrane filtration to make the chip operation more scalable. In effect, the chip looks like a standard membrane filter, but under an electron microscope the microfluidic chip reveals its delicate structure used to capture clusters while letting other blood cells pass through.

Practicality was just as important as functionality to the researchers. Although the chip is initially fabricated with silicon just like a central processing unit in a computer, it is later transferred to polymers to make it accessible, affordable, and single-use, while still retaining its delicacy and precision.

“We really created only the traps that we need to have for recognizing the clusters with the microfluidic chip, and the rest is just a standard filter holder,” Sarioglu said. “Compared to a conventional microfluidic chip, you will get a much more practical assay with orders of magnitude improvement in throughput and a higher sensitivity.”

Analyzing Patient Tumor Cell Clusters

The researchers used the chip to screen blood samples from patients with ovarian or prostate cancers through a partnership with the Emory and Northside Hospitals. They isolated CTC clusters ranging from two to 100 or more cells from prostate and ovarian cancer patients and used RNA sequencing to analyze a subset.

The chip’s unique design means CTC clusters are filtered in microwells and can later be accessed for further analysis. Even a single CTC can contain a significant amount of data on the patient and their specific cancer, which can be critical for managing the disease. For example, the researchers noted hundreds of CTCs in clusters in the blood of ovarian cancer patients, some still alive, a finding that could be consequential to the spread of the disease.

Also, by sequencing the RNA in prostate CTC clusters isolated by the chip, the researchers identified specific genes expressed by these metastasizing cells. Importantly, CTC clusters from different patients were shown to express different genes, which can be potentially utilized to develop personalized, targeted therapies. Sarioglu envisions Cluster-Wells as being a routine part of the treatment process to determine what stage the cancer is at from a simple blood draw.

“Finding these clusters was very elusive,” Sarioglu said. “But this is a technology that allows these precious circulating tumor cell clusters virtually in any cancer to be accessed with precision and practicality that has not been possible before.”

CITATION: Boya, M., Ozkaya-Ahmadov, T., Swain, B.E. et al. High throughput, label-free isolation of circulating tumor cell clusters in meshed microwells. Nat Commun 13, 3385 (2022). https://doi.org/10.1038/s41467-022-31009-9

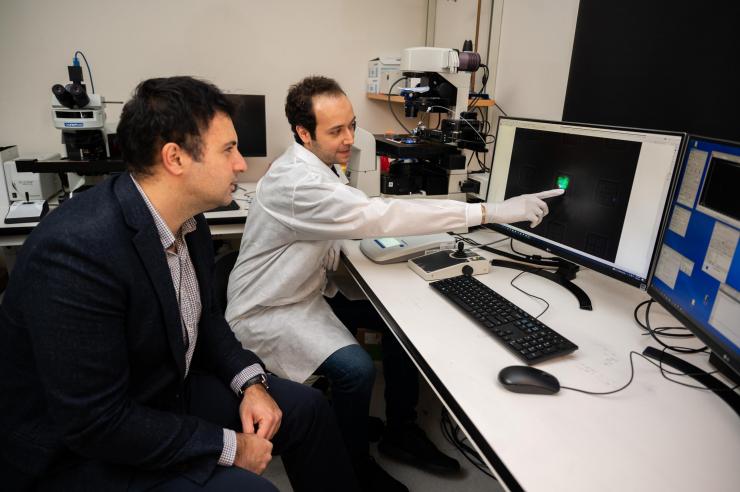

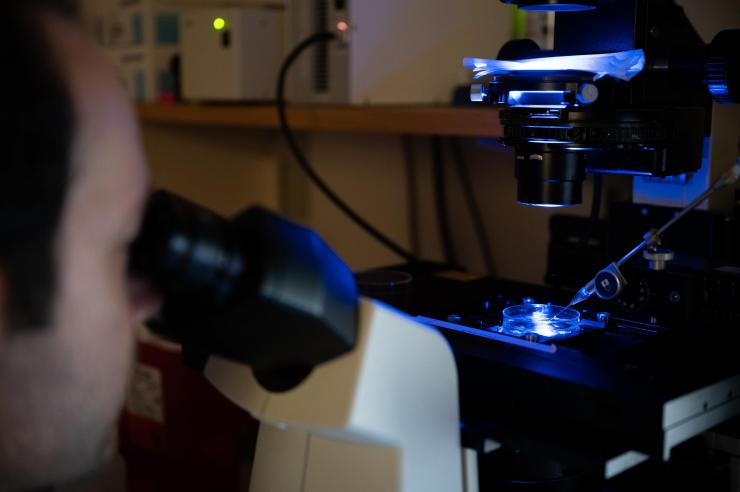

A circulating tumor cell cluster isolated from a prostate cancer patient blood sample is being imaged with a fluorescence microscope. Tumor cells are labeled with a green fluorescent label for identification.

Tumor cells harvested from patient blood samples are being picked from the device for sequencing. The device is in a Petri dish on the microscope stage. A glass micro capillary collects the circulating tumor cell clusters.

Prof. A. Fatih Sarioglu (front) and the graduate student Mert Boya are near the instrumental setup used to process the patient blood samples.

Tess Malone, Research Writer/Editor

Top Prize Awarded to Lim, Agnesina for 3D IC Design Methodology Research

Aug 11, 2022 — Atlanta, GA

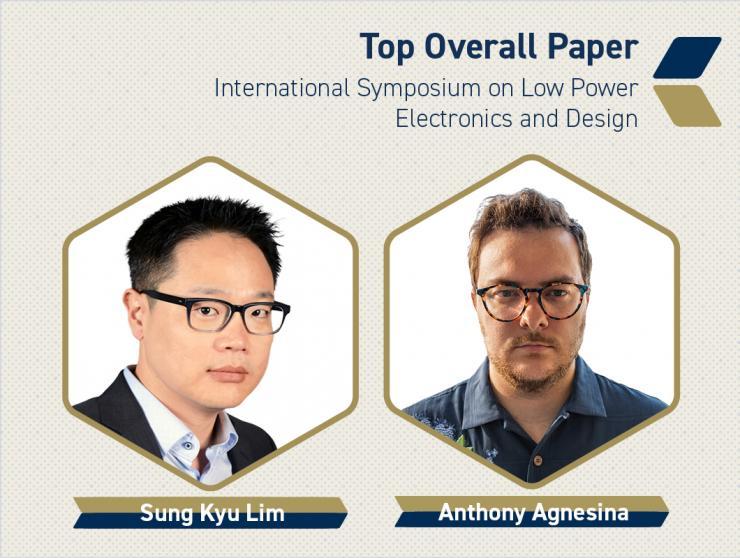

Georgia Tech professor Sung Kyu Lim and recent Ph.D. graduate Anthony Agnesina

The award-winning article proposes a novel hierarchical physical design flow enabling the building of high-density and commercial-quality two-tier face-to-face-bonded hierarchical 3D ICs.

Georgia Tech professor Sung Kyu Lim and recent Ph.D. graduate Anthony Agnesina have won the top paper award at the 2022 International Symposium on Low Power Electronics and Design (ISLPED) for their research entitled, “Hier-3D: A Hier archical Physical Design Methodology for Face-to-Face-Bonded 3D ICs.”

Lim is a Motorola Solutions Foundation Professor in Tech’s School of Electrical and Computer Engineering (ECE) and Agnesina is currently a research scientist at NVIDIA and was advised by Lim while at Georgia Tech. Co-authors include eight researchers from the Interuniversity Microelectronics Centre (IMEC), the University of Bremen, ETH Zurich, and the University of Bologna.

The award-winning article proposes a novel hierarchical physical design flow enabling the building of high-density and commercial-quality two-tier face-to-face-bonded hierarchical 3D ICs. Hierarchical very-large-scale integration (VLSI) flows are an understudied yet critical approach to achieving design closure at giga-scale complexity and gigahertz frequency targets.

The authors significantly reduced the associated manufacturing cost compared to existing 3D IC implementation flows and, for the first time, achieved cost competitiveness against the 2D reference in large modern designs.

Experimental results on complex industrial and open manycore processors demonstrate in two advanced nodes that the proposed flow provides major power, performance, and area/cost (PPAC) improvements of 1.2 to 2.2× compared with commercial 2D ICs, where all metrics are improved simultaneously, including up to 20% power savings.

ISLPED was held at the Boston University Electrical and Computer Engineering Department / Photonics Center on August 1-2, 2022. The symposium is the premier forum for presentation of innovative research in all aspects of low power electronics and design, ranging from process technologies and analog/digital circuits, simulation and synthesis tools, system-level design, and optimization, to system software and applications.

Dan Watson

dwatson@ece.gatech.edu

Fall 2022 Short Course on Soft Lithography for Microfluidics

This course module is designed for individuals interested in hands-on training in the fabrication of microfluidic devices using the soft lithography technique. It is structured to assume no prior knowledge of the technologies by the participants. The course agenda is evenly divided between hands-on laboratory sessions, including SU-8 master mold creation using photolithography and PDMS device fabrication in the IEN cleanroom, and supporting lectures.

Georgia Tech’s $26 Million Partnership with National Science Foundation to Transform Fertilizer Production

Aug 10, 2022 — Atlanta, GA

Paul Kohl (School of Chemical and Biomolecular Engineering) and Marta Hatzell (George W. Woodruff School of Mechanical Engineering) will lead CASFER’s efforts at Georgia Tech.

The Center for Advancing Sustainable and Distributed Fertilizer Production (CASFER) is a collaborative effort between the National Science Foundation (NSF) and five universities.

Thanks to efforts to combat climate change, many have heard the catchphrase “closing the carbon loop” — a global effort to convert carbon dioxide into something useful to mitigate the damaging effects of pollution on the planet. Another environmental challenge relates not to carbon dioxide but nitrogen. Now, an ambitious plan to close the nitrogen loop is underway, and with it comes the potential to revolutionize agriculture in the U.S. and around the world.

The Georgia Institute of Technology will be part of CASFER, an NSF Engineering Research Center (NSF-ERC), with four other universities. Supported by an initial grant of $26 million from NSF, CASFER seeks to transform the U.S. from nitrogen cycle pollution to a nitrogen circular economy by developing new technologies and programs for capturing, recycling, and producing decarbonized nitrogen-based fertilizers (NBFs). Georgia Tech is joined by Florida Agricultural and Mechanical University, Case Western Reserve University, the Massachusetts Institute of Technology, and Texas Tech University, which will lead the effort and serve as CASFER’s headquarters.

Nitrogen is used in many commercial applications, but one of the most significant uses is in NBFs for growing food. NBFs are put out into fields, but most do not get used — 80% are washed away and wasted, ending up as pollutants in the watershed. With support from NSF, this team of universities will attempt to recover and reuse nitrogen compounds, the principal element in fertilizers.

“By taking pollutants out of the water and converting them for use, we are taking a negative and making a positive out of it,” said Paul Kohl, Regents' Professor and Thomas L. Gossage Chair in the School of Chemical and Biomolecular Engineering (ChBE) and co-lead of the CASFER effort at Georgia Tech, along with Marta Hatzell, associate professor in the George W. Woodruff School of Mechanical Engineering. “This process will both decrease pollution and lower the cost of farming.”

CASFER has three areas of focus it will pursue to achieve its goal. The first involves measuring and analyzing data to identify new opportunities and locations for collecting wasted fertilizer and determining how exactly the fertilizer affects individual environments.

The second area — Kohl and Hatzell’s focus — is the actual collection and separation of nitrogen compounds from the three types of environments where they usually show up: produce farms, livestock farms, and wastewater treatment plants. They will develop specialized separation methods to pull nitrogen pollutants out of the various environments, creating new types of polymer membranes that work to separate and concentrate the compounds into solutions that can be converted for future use. The work will start in the laboratories at Georgia Tech, but later the team will build test beds — portable laboratories the size of small trailers — to test their separation methods on-site.

“All our separations technologies will be modular, electrified, and largely decarbonized,” said Hatzell. “Our overall goal is to design processes that synthesize new or recover used fertilizers from waste at the same or lower price than traditional chemical manufacturing processes.”

The third area is reconverting the concentrated solutions into usable fertilizer. Humans have been making fertilizer the same way for more than 100 years, using an expensive chemical process that requires natural gas — a resource in short supply. CASFER researchers will develop the conversion methods to create new fertilizers and strategies for dispensing it back into fields for growing crops.

“One strength of NSF Engineering Research Centers is their ability to bring interdisciplinary academic teams together in convergent research to identify novel approaches to thorny societal challenges,” said NSF Assistant Director for Engineering Susan Margulies. “With their unique testbeds and industry partners, the centers innovate and translate solutions that are effective and sustainable.”

CASFER is poised to bring about dramatic changes to the agriculture industry. Since the inception of the Engineering Research Centers program in 1985, the NSF has awarded fewer than 100 grants to open ERCs, which are designed to foster innovation and collaboration between industry leaders, government agencies, and institutions of higher education.

“For decades, NSF Engineering Research Centers have transformed technologies and fostered innovations in the United States through bold research, collaborative partnerships, and a deep commitment to inclusion and broadening participation,” said NSF Director Sethuraman Panchanathan. “The new NSF centers will continue the legacy of impacts that improve lives across the nation.”

Looking to the future, universities will launch workforce development efforts like training and education to prepare a new generation of farmers and scientists for work in the nitrogen circular economy.

Georgia Tech researchers involved in the grant include Kohl (Co-Thrust Leader), Andrew Medford, and Joseph Scott from ChBE; Peter Hesketh (Co-Thrust Leader) and Hatzell (Thrust Leader/Co-PI) from the Woodruff School; Mary-Lynn Realff from the School of Materials Science and Engineering; Lizanne DeStefano (EWD Lead) from CEISMC; and Jie Xu and Milad Navaei from the Georgia Tech Research Institute.

Catherine Barzler, Senior Research Writer/Editor

catherine.barzler@gatech.edu