Licensing Georgia Tech Materials Innovations

Georgia Tech offers a large portfolio of available technologies in materials that can help solve industry R&D challenges.

We help Georgia Tech innovations and discoveries benefit the public by allowing industry to license and continue to develop and commercialize these cutting-edge innovations.

Available Technologies:

Electronic Materials

Cascaded Nickel Hard Mask

William Doolittle | Joseph M. Pettit Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

Many emerging high-power power devices require large, multiple micron-deep mesa structures that are typically etched by a plasma process, which necessitates masks to protect regions from the aggressive plasma-etch. Unlike small-depth mesas that can use thin masks, many high-density metals used for mesa protection experience significant stresses and adhesion issues when deposited in thicker layers suitable for the protection of etched thick mesas. Additionally, some forms of metal masks alloy with the semiconductor they are designed to protect, creating substantial damage and potential contamination when the mask is removed in later processing steps. The Georgia Tech innovation alleviates these difficulties.

Thin Current Spreading Layers Improve Breakdown Performance

William Doolittle | Joseph M. Pettit Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

This new approach to current spreading in quasi-vertical diodes avoids excessive current flow, field crowding, and premature breakdown at the mesa edges. It does this by improving electrical current uniformity in group III-nitride devices with thin current spreading layers (CSL). By sandwiching a thin gallium nitride (GaN):beryllium (Be) i-layer thin film inside the n-type GaN layer, the current uniformity dramatically increases from approximately 40% of the p-contact radii to nearly 100%, resulting in higher breakdown performance and reduced current leakage. This technology can be applied to any thickness drift layer and has been shown to be particularly effective for thicker drift layers needed for high voltage devices. It can be used for any Ga-containing alloy (e.g., aluminum-gallium-indium-nitride [AlGaInN]).

A Method for Creating a Protective Cap Layer for Semiconductor Wafers

William Doolittle | Joseph M. Pettit Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

Hybrid growth approaches to producing III-nitride-based semiconductor wafers have been shown to improve performance. This is due to the fact that no one deposition system can provide the best of all needed benefits. For instance, metal organic chemical vapor deposition (MOCVD) results in growth of high-quality LED and solar cells structures, but molecular-beam epitaxy (MBE) deposition is better suited to doping. To get the benefits of both, a process that leverages both types of deposition systems is advantageous but exposes samples to contamination when transferring between systems. These impurities get incorporated into any film or layers grown on top of them, resulting in defects and degrading performance. Georgia Tech’s method of producing a protective layer that can be evaporated during the deposition of the second layer directly addresses this problem.

p-type Be-Doped AlN Films and Layered Films

William Doolittle | Joseph M. Pettit Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

Because the limitation in the development of high-performance AIN-based devices was previously challenged in AIN doping, this new MME method enables the creation of p-type AlN:Be films as key components in ultra-wide bandgap (UWBG) semiconductors and semiconductor devices. Extension of this technology uses layers of these films with other WBG materials to access JBS and SBD diodes for use in UWBG applications as high-power, high-voltage, high-frequency devices capable of operation in extreme heat and radiation environments. This experimental achievement opens new doors for AIN-based novel deep ultraviolet, high-power, and high-frequency devices.

Self-Powered Highly Stretchable Sensing Interface for Gesture Recognition

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Serpentine’s flexibility and small size makes it ideal for integration into wearable, on-body human-computer interface applications to allow for natural and unobtrusive interactions. Beyond its potential for gesture recognition and assistive technologies, other applications could include human motion and health monitoring, structural health monitoring of buildings, and even electric musical instruments.

Chip-Scale Electrochemical Double-Layer (ECDL) Supercapacitors

W. Jud Ready | Principal Research Engineer; Georgia Tech Research Institute

Potential Commercial Applications

This novel chip-scale electrochemical double-layer (ECDL) supercapacitor uses carbon nanotubes to provide high-power energy storage for low-volume and low-weight microelectronics systems. Traditional ECDL approaches that utilize activated carbon often have limitations imposed by the structure of their pores. Georgia Tech’s nanostructured carbon–based ECDL electrodes offer improved performance due to their high surface area, high conductivity, increased porosity, and options for functionalization that enhance pseudocapacitance (i.e., electrochemical storage of electricity).

Post-Processing Side Chain Cleavage to Enhance Conjugated Polymers

John Reynolds | Professor; Chemistry & Biochemistry and Materials Science & Engineering

Potential Commercial Applications

This method for removing large side chains from conjugated polymers (CPs) can significantly increase the electrical and thermal conductivity of polymer films used in myriad applications ranging from batteries to advanced display technologies. Utilizing post-processing hydrolysis for side chain removal, Georgia Tech’s innovation can be applied to high-performance polymer repeat unit structures. Doing so yields an average conductivity of more than 450 siemens/centimeter (S/cm)—the highest value of any non-PEDOT dioxythiophene-based material. The method even outperforms any currently available oligoether/glycol-based CP system, making it ideal for applications requiring highly conductive materials.

High-Performance Broadband Photodetector

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Georgia Tech’s innovation has a 3D photodiode structure that features a specially designed textured top electrode with nanowire arrays to maximize light absorption. A conformal alumina layer is inserted between two constituent semiconductors of a p-n junction to form dual inversion layers. This unique structure leads to significant enhancement of photo-excited charge carrier separation and collection efficiency. The photo-sensing responsivity and sensitivity are nearly one order of magnitude higher than that of a reference device of p-Si/N-ZnO nanowire arrays. This innovation potentially paves the way for a practical and efficient approach to converting light to electricity, resulting in high-performance broadband photodetectors and other optoelectronics.

Optical Architecture Enables High-Performance Chips

Ali Adibi | Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

Photonics technology offers unique solutions for accelerator chips to work in conjunction with electronic processors to enable computations that are not feasible with current processors. Most existing ideas for implementing high-performance optical computing systems rely on conventional optical neural networks (NNs). However, implementing artificial NNs with photonic chips is difficult due to the limited control on optical connections and nonlinearities. Additionally, errors caused by fabrication imperfections deteriorate the performance of manufactured chips. These limitations make the training of optical computing chips increasingly challenging and restrict optical NNs to low-efficiency processors with a small number of neurons—not useful for solving real-world computing and modeling problems.This Georgia Tech innovation offers a new paradigm for high-performance computing hardware that can be adopted by a variety of platforms.

Hybrid Meta-Surfaces for Active, Non-Volatile Light Manipulation

Ali Adibi | Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

This Georgia Tech innovation lays a foundation for reconfigurable hybrid plasmonic-photonic meta-surfaces as promising candidates for the development of miniaturized energy-harvesting, optical-sensing, and imaging meta-systems. To determine feasibility, researchers experimentally demonstrated miniaturized tunable meta-surfaces that globally manipulate the amplitude and phase of incident light necessary for near-perfect absorption and anomalous/specular beam deflection.

Hybrid Triboelectric Nanogenerator Harvests Mechanical and Electrical Energy

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Interest in technologies that can harvest renewable energy from the environment is increasing and, while Georgia Tech has developed several applications for the TENG, this variation can be used in wet conditions and utilizes contact electrification with sources other than solid materials. Innovations like this hybridized TENG are particularly desirable in remote locations where power sources may be sparse or for agencies looking to save costs by reducing the power consumption of their systems. Such a technology would also be highly useful across industries that require remote sensing applications, including military/aerospace, wireless networks, energy and utilities, environmental monitoring, oceanography, manufacturing, automotive and aerospace electronics, and even for medical devices.

High-Performance Broadband Photodetector and Power Generator

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

The photovoltaic effect has been widely investigated in solar cells as a sustainable energy source that could replace fossil fuels. While the direct current generated by conventional photovoltaic technologies—like solar panels—is useful, this Georgia Tech method that produces alternating current generates significantly more current overall and broadens the potential applications of the photovoltaic effect. Additionally, this process allows for photodetector devices to operate without a voltage bias and with a high sensitivity, even at low light intensity. It could also be used to boost the power output from photocells.

Available Technologies:

Biomedical Materials & Devices

New Methods for Skin Tissue Engineering:

Textile-Based Sandwich Scaffold and CNT-based

Electrospun Polymer Composite Yarns

Ben Wang | Gwaltney Chair in Manufacturing Systems, Professor Emeritus in Materials Science & Engineering, Georgia Tech Chief Manufacturing Officer, and Chair of the National Materials and Manufacturing Board

Potential Commercial Applications

These new methods for tissue engineering address the challenges of building scaffolds that exhibit the properties of real human tissue. Georgia Tech’s innovations leverage a method using fabricated polycaprolactone (PCL) yarns by wet electrospinning. The PCL yarns can be used for constructing a textile-based sandwich scaffold that—unlike existing scaffold fabrication methods—mimics the strain-stiffening behavior observed in human tissues. Additionally, carbon nanotubes (CNT) can be incorporated into the yarns, providing conductive properties to the polymer composite.

Wearable Health Monitoring Device Improves Data Quality and Accuracy

W. Hong Yeo | Associate Professor; School of Mechanical Engineering

Potential Commercial Applications

Unlike conventional sensors and systems that operate with aggressive adhesives or straps—and often lose valuable data due to significant MA interference—Georgia Tech’s chest-mounted innovation adheres to the skin with a breathable soft membrane for continuous conformal contact. In testing against commercially available skin-mounted biosensors, the new device provided real-time wireless data of multiple physiological signals with a significant reduction in MA interference. Additionally, trial participants experienced few or none of the challenges typical of conventional health monitoring devices, including device lamination issues, signal degradation, excessive sweating, or skin irritation.

Next-Generation Custom-Fit Reusable Mask for Respiratory Protection

Sundaresan Jayaraman | Professor; School of Materials Science and Engineering

Potential Commercial Applications

N95 respirators are designed to protect wearers from the transfer of microorganisms, body fluids, and particulate matter. Their successful deployment depends on factors such as fit, comfort, shape conformance, and durability. Current respirators are intended for a single use and fabricated from non-woven materials. They require fit-testing to ensure proper protection, a tedious and time-consuming process, particularly during emergencies, such as the COVID-19 pandemic. This transformative Georgia Tech innovation has the potential to ensure proper and customized fit and eliminate face-seal leakage, leading to comfortable and cost-effective respiratory protection. The use of 3D-printing technology and polymer materials enables a reusable and novel approach to respiratory protection.

Rotary Mechanism for Lab-on-a-Chip Microvalves

Peter Hesketh | Professor; School of Mechanical Engineering

Potential Commercial Applications

This invention features a novel in-plane rotary bistable mechanism (IPRBM) that can produce rotational motion in microelectromechanical system (MEMS) devices. Designed particularly for use in microfluidic systems, this MEMS component overcomes the limited mechanical displacement provided by typical linear micromechanisms. Georgia Tech researchers have leveraged this IPRBM to produce a rotary gate microvalve that operates on a chip with a small sample volume, rapid response time, and low power consumption while maintaining a high flow rate. It relies on the bistable mechanism to provide rotary motion and regulate the flow path of the microvalve design. This rotary mechanism has several additional applications, including in opto-MEMS devices, biomedical devices, microlocks, and sensors.

Novel Polymer Hybrid Improves Stability of Implantable Devices

Meisha Shofner | Associate Professor; School of Materials Science & Engineering

Potential Commercial Applications /h6>

Nearly 75 percent of back pain is attributed to degenerated or damaged spinal discs. Surgical spinal fusion is a common remedy but can limit patient range of motion. Artificial IVDs are a growing technology designed to treat damaged discs as they provide greater comfort and flexibility. Consisting of a fibrous set of rings encircling a gel-like center, they permit dynamic rotational and compressive movement. Georgia Tech’s PVA-based polymer material is easily processed into a variety of constructs with no need for additional chemicals. Designed for use as an artificial IVD, it can be used for other fibrocartilage replacements and also offers potential for applications that require a modifiable compressive use.

Available Technologies:

Sustainable &

Renewable Materials

Micro Ammonia Production System (MAPS)—Systems and

methods for making nitrogen-based compounds

Mostafa El-Sayed | Regents' Professor Emeritus; School of Chemistry

Potential Commercial Applications

This MAPS ammonia production technology uses hollow hybrid plasmonic nanocages to create a highly effective electrocatalyst for ammonia synthesis from nitrogen (N2) and water (H2O) under ambient temperatures and pressure in the gas- and liquid-phase system. As a major energy carrier and a critical ingredient in producing fertilizers, ammonia is widely produced globally. To meet these ammonia demands, Georgia Tech researchers have developed this sustainable and environmentally friendly production method that enables a high ammonia yield rate with unprecedented Faradaic and energy efficiency. This technology decentralizes the production of ammonia while consuming significantly less energy than current methods, permitting local or on-site production with renewable electricity sources and long-term energy storage.

Nanoparticle-Stabilized Carbon Molecular Sieve Membranes for Efficient, Large-Scale Gas Separation

William Koros | Professor; School of Chemical & Biomolecular Engineering

Potential Commercial Applications

This technology is designed to reduce CMS fiber collapse during pyrolysis while allowing for economical integration into CMS precursor formation. Substructure collapse can result in increased thickness of the separation layer—which often causes a drastic loss in gas permeance—and its prevention is important for the enabling of practical CMS applications. Tests show that a multilayer CMS precursor hollow fiber with an inner nanoparticle core support layer and an outer sheath layer can eliminate the need for post-treating precursor fibers. Elimination of this additional conventional method for preventing collapse can reduce cost and complexity to the fabrication process.

Quasi-Melt Processing Technique for Stronger Single-Polymer Composites

Donggang Yao | Professor; School of Materials Science & Engineering

Potential Commercial Applications

This processing technique strengthens single-polymer composites (SPCs) and makes it easier to mass produce them using conventional melt processing methods. SPCs are comprised of fibers and matrices that are made from the same polymer. When compared with heterogeneous composites, SPCs offer superior impact resistance, reduced weight, and enhanced recyclability while maintaining high mechanical strength.

Sustainable Combination Technology Delivers a Long-Lasting Self-Powered Battery

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Conventionally, power sourcing has been siloed into two technologies: energy generation and energy storage. The discovery of TENG technology in 2012 introduced new possibilities for low-cost and highly efficient energy generation, but it lacks stability due to its ambient environment. Meanwhile, energy storage has had few significant improvements since the Li-ion battery became commercially available in 1991. The researchers at Georgia Tech have identified the benefit of combining TENG and Li-ion batteries to create this self-charging power unit that is sustainable, continuous, and eco-friendly.

Zeolite Membrane Sieves Fabricated on Low-Cost Alumina Hollow Fiber Substrates

Christopher Jones | Professor & John F. Brock III School Chair; School of Chemical & Biomolecular Engineering

Potential Commercial Applications

Innovators at Georgia Tech have developed novel methods for fabricating low-cost zeolite membranes used in molecular separation techniques. Both methods offer a path forward for utilizing zeolite sieves to accelerate scale-up and applications of thin, selective membranes for separating gases and other molecules for energy production, greenhouse gas mitigation, and other applications.

Novel Thin-Film Coatings for Enhanced Solid Oxide Fuel Cell (SOFC) Cathodes

Meilin Liu | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Intensive research has been conducted in the field of fuel cell technologies in the search for a clean and sustainable energy supply that has low environmental impact. Fuel cells provide high conversion efficiency through direct conversion of chemical fuels to electricity, with solid oxide fuel cells having the greatest potential due to their use of low-cost ceramic materials and extremely high electrical efficiencies. SOFCs can use a wide variety of fuels, including hydrogen and hydrocarbons, coal gas, and bio-derived fuels. However, significant technical challenges have inhibited commercialization of SOFCs because they require high operating temperatures (generally above 800°C), which requires the use of expensive materials and creates engineering challenges. This technology’s enhancement of cathode activity represents a vital step toward successful reduction in operating temperature since the resistance to oxygen reduction reaction contributes the most to energy loss in existing SOFCs, and even more so at lower temperatures.

Hybrid Zeolitic Imidazolate Frameworks for Effective Gas Separation

Christopher Jones | Professor & John F. Brock III School Chair; School of Chemical & Biomolecular Engineering

Potential Commercial Applications

Georgia Tech researchers have developed hybrid zeolitic imidazolate framework (ZIF) materials that allow for the continuous tuning of their porosity and functionality. ZIF materials in general contain metal centers connected by imidazole linkers. The continuous control over pore characteristics (like size, shape, flexibility, and functional groups) of the hybrid ZIFs means that the materials can be tailored to a specific application, like for CO2/N2 or CO2/CH4 separations for natural gas purification. Leveraging the inherently advantageous properties of ZIF—thermal and chemical stability, high microporosity, and high surface area—researchers have prepared this new model of material to include more than one type of imidazole ligand simultaneously in a tunable manner, a differentiating feature from earlier ZIF models. A unique method of synthesis produces hybrid materials with properties distinctly different from the parent single-linker materials. This synthesis technique provides a platform for tuning functionality or porosity based on the ligands used.

Piezoelectric Nanogenerator for Self-Powered, Energy-Harvesting Sensors

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Renewable and green energy sources are needed for sustainable, maintenance-free, and continuous operation of small-scale electronics, such as implantable biosensors, nanorobotics, and mobile environmental sensors. The research team has developed nanogenerators that operate not only as self-sufficient power sources for micro- and nano-systems but also as self-powered sensors for detecting motion, vibration, or any mechanical disturbance. This super-flexible and conformable nanogenerator can not only enable energy harvested from a waving flag but also detect skin movement when attached to a human face.

Alternative Plastic Solution Using Chitin Nanofibers

J. Carson Meredith | Executive Director of the Renewable Bioproducts Institute

Potential Commercial Applications

There is immense interest in producing packaging plastics from renewable resources. Plastics are often used to protect food from oxygen and water, and due to not being produced by renewable resources, they are difficult to recycle or biodegrade. Chitin, a natural sugar compound and the second most abundant biopolymer in nature, is a sought after bio-derived material for its high stiffness, strength, and protective barrier properties and its natural nanofiber structure. Current extraction and processing techniques rely on strong acids and bases or volatile organic solvents that reduce chitin’s sustainability and diminish its natural properties. Thus, there is a need for a processing method that retains the properties of chitin while producing a functional product.

Available Technologies: Next-Gen

Materials; Development & Characterization

Molecular Flux Measurement Device and Method

William Doolittle | Joseph M. Pettit Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

This new device and method enable users to measure the molecular flux leaving an effusion cell in a molecular beam epitaxy (MBE) system. Georgia Tech’s innovation consists of a metallic crucible with an optional dielectric shield. An optional metallic outer coating is designed to act as an insulator and guard terminal. The technology can be used in a closed-loop control system to provide in-situ flux control and stability by feeding an amplified current signal to a process controller. This configuration enhancement of an in-situ measurement (versus ex-situ) results in greater efficiency and enables a threefold improvement in speed compared with existing technology while eliminating unreliable variations and long-term drifts.

Zeolitic Nanotubes for Advanced Chemical Catalysis and Separation

Christopher Jones | Professor & John F. Brock III School Chair; School of Chemical & Biomolecular Engineering

Potential Commercial Applications

This Georgia Tech technology is designed to provide the next generation of hierarchical zeolite materials by combining microporous zeolites and mesoporous materials. The nanotubes are perforated with micropores and also maintain a mesoporous structure in their central channel without collapsing, an advancement of the current state of the art. In this way, the material could allow for new types of chemical processes that would not be possible with conventional zeolites.

Non-Aqueous 2D Material-Based Hydrogen Isotope Separation

Eric Vogel | Professor; School of Materials Science & Engineering

Potential Commercial Applications

Inventors at Georgia Tech describe the design and methods for production of an ion selective hydrogen pump using solid state proton conductors coated with 2D materials (graphene and hBN). Isotope separation is the process of removing excess ions to identify a concentration of specific isotopes. Currently, 2D materials have been shown to exhibit ion selectivity when operated as a simple hydrogen pump. However, delivery of the hydrogen to the 2D material is of critical importance to a functioning device with adequate efficiency. Importantly, the conductivity of unique nuclei across the 2D material is significantly higher than that of atoms or molecules. For this reason, a proton conductor must be coupled to the 2D material to fabricate a functioning device.

Available Technologies:

Advanced Manufacturing

Materials & Processes

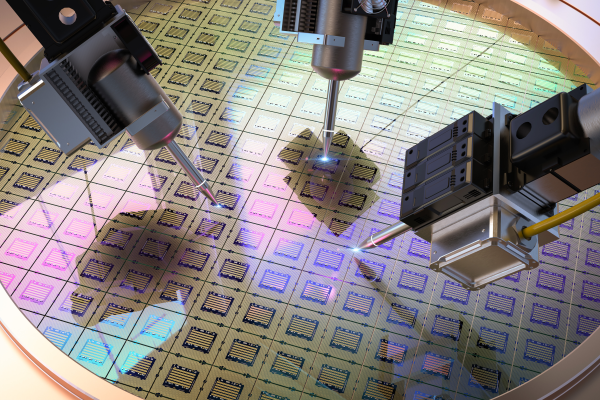

Heterogeneous Integration Method for III-Nitride Devices

Abdallah Ougazzaden | Professor; School of Electrical & Computer Engineering

Potential Commercial Applications

As the electronics industry enters an era of acceleration and disruption, heterogeneous integration will become an important component for emerging technology fields, such the Internet of Things (IoT) and advanced communication technology. One approach to heterogenous integration is the transfer of epilayers from their native growth substrate to a dissimilar receiving substrate. A range of epitaxial layer separation approaches have been developed, such as laser liftoff and chemical liftoff, but their use is limited by high costs and long processing times.This Georgia Tech innovation utilizes a mechanical liftoff technique that is fast and results in smooth separated surfaces, facilitating epitaxial growth on large wafers and enabling the development of industrial-scale III-Nitride-based integrated devices.

High-Caliber 3D and Aerosol Jet Printing with Regenerated Silk Fibroin (RSF)

Kyriaki Kalaitzidou | Rae S. and Frank H. Neely Professor; School of Mechanical Engineering

Potential Commercial Applications

Silk has been hailed as a multi-purpose material for centuries, thanks to its versatile mechanical properties, biocompatibility, and biodegradability. Its use in industries like medicine and food production, however, requires an efficient, non-contact printing method that can produce highly precise patterns. Aerosol jet printing has been identified as a promising technique for developing objects from RSF, as it can process drop volumes much smaller than inkjet printing and with a wider range of viscosity. To address the issues of RSF’s low printability in aerosol jet printers, this technology prepares and fabricates RSF material in such a way that—when combined with particular parameters—it can print high-quality samples with more ease and adaptability.

Electrohydrodynamic Jet Printing Driven By a Triboelectric Nanogenerator

Zhong Lin Wang | Regents' Professor; School of Materials Science & Engineering

Potential Commercial Applications

Electrohydrodynamic jet (e-jet) printing is a high resolution printing solution where an electric field is used to print liquid through micro/nano-scale nozzles, as opposed to acoustic or thermal energy. The technology is commonly used for micro/nano manufacturing for patterning materials onto substrates. Among others, a big setback for commercializing this technology has been slow printing speeds. There is a need to increase printing speeds, lower cost, and produce higher resolution.