Paper, Board, and Box Testing

To view Physical Testing of Paper on the screen, click on the center of the above graphic. To download the book, click here.

Paper Board/Box Testing at RBI has over 5600 square feet of lab space dedicated to address any paper, board, corrugated board/box and specialty product testing needs in areas of strength, optical, surface, and structural properties. In addition to a full complement of conventional Tappi method testing capabilities, the Paper Testing group can provide special services in the areas of environmental simulations and accelerated aging. Synergistic collaboration with RBI Chemical Analysis labs provides an unparalleled trouble-shooting capability to address any industry quality or production issue. Three large walk-in environmental chambers cover high and low temperature and humidity conditions. Unique capabilities include:

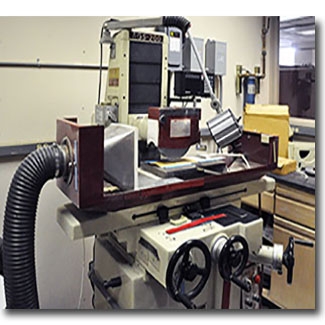

- Precision paper grinding or sheet splitting to produce specific thickness sections

- Score cracking of linerboards: measurement of crack angle by RBI method or cracking propensity by the AF&PA method

- Needle abrasion testing to predict relative slitter and knife blade wear caused by abrasive components in both base sheet and coating materials

- Nondestructive in-plane and out-of-plane (Z-directional) ultrasonic testing

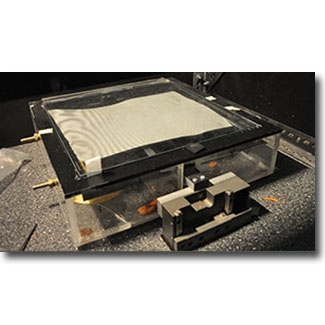

- Optical 3D Moiré surface topography and processing software for the measurement of curl or cockle

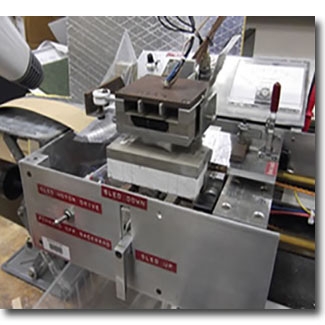

- An automated double backer simulator can fabricate 12 x 2” corrugated board samples for evaluating adhesive efficacy and application

- A torsion pendulum can measure the out of plane shear rigidity which is a sensitive measure of board crush on board physical properties in complement to the acoustic resonance “BQM” method

- Large platen 4 x 5’ box compression tester up to 20,000 lbs

- A twelve channel ECT creep measuring apparatus is available for evaluating lifetime performance of corrugated boards

- A programmable walk-in humidity chamber is also fitted with 8 accelerated creep measuring stations for corrugated box lifetime studies

Our labs also offer the latest automated capabilities for real time hygroexpansive response measurements, and horizontal plane static and kinetic coefficient of friction determinations. Humidity and temperature conditions are monitored and tracked continually to ensure proper standard Tappi conditions of 23 degrees C and 50 % RH.

The results from the RBI Paper Analysis Laboratory have been validated through RBI active participation in the Collaborative Testing Services Inc., and PAPRICAN Paper and Pulp Monitor programs. Along with routine internal checks using calibration standards, this ensures that the equipment, methods and results are consistent with correct industry practice.

Each contract is concluded with the issue of a formal report of measurements and analyses/graphs/interpretation via e-mail. Typical turn-around time for projects is 5 business days from receiving samples. Projects are initiated through contact with the IPST lab manager. A PO number or billable credit information sent through e-mail to Roman.popil@ipst.gatech.edu will get a project going.

Equipment

Available equipment shown (bottom of this page).

Paper Testing

- RBI developed out-of-plane ultrasonic time-of-flight measurement

- Tear testing in progress

- RBI developed programmable robotic arm for in-plane ultrasonic measurements

- Emveco stylus, Emveco caliper and Mullen burst testers

- Optical properties measuring instruments: brightness, color, gloss, opacity

- Hygroexpansimiter for CD profiles of paper machine-wide strips

- Physical properties testing instruments: Out-of-plane ZTD, 4 point bending, high-pressure Mullen tester

- Compression tester for ECT pin adhesion and ring crush, Bristow wheel for ink absorption testing

- RBI developed general use robotic arm for in-plane stiffness measurements

- Taber bending stiffness, Parker Print-Surf roughness measurement instruments

- Instron test frame for generalized compression and tensile testing

- RBI developed variable humidity programmable tensile creep tester

- Tensile tester

- Video formation tester

- 2 point bending stiffness tester

- Variable environmental chambers

- Taber abrasion tester

- L&W densometer

- Out-of-plane/In-plane ultrasonic tester

- Handle-O-Meter "handle" or hand-feel tissue softness tester

- Scott Bond Tester

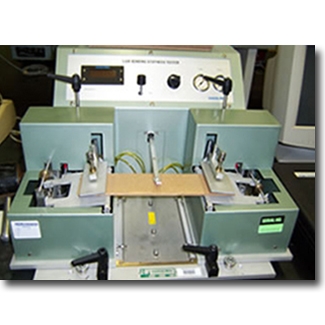

- Amontons II ISO Method Friction Tester

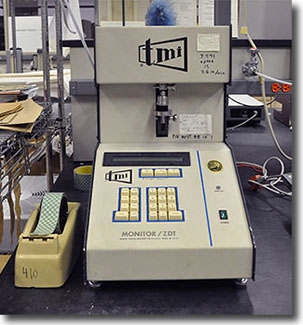

- Zero Span Tester

- ZD Tensile Tester

- Sutherland Rub Tester

- Paper Mullen Tester

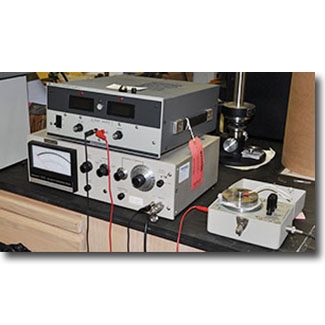

- Surface Resistivity

- Optical Moire Shadowgraphy

- Precision Grinder

- Computerized Oven for Moisture Solids and Ash

- Bendtsen and Sheffield Air Leak Method Roughness Testers

- Hot Coefficient of Friction (HCOF) tester detail

- Cycling Paper Bag Handle Tester

- Corrugated Board Puncture T 803 (GE) Tester

- Frazier Air Permeability

- Vapo-meter Cups Set-up for Moisture Vapor Transmission MVTR

Board Testing

- 4 Point Bending Stiffness Tester

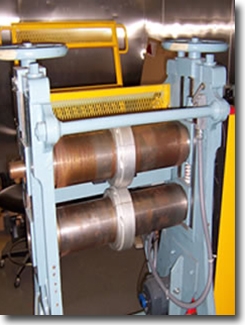

- Double Backer Simulator

- Mullen for Corrugated Board

- Billerud Cutter for T 839 ECT Samples

- Honshu AR&PA Score Crack Tester

- Crush Tester with T 839 Fixtures

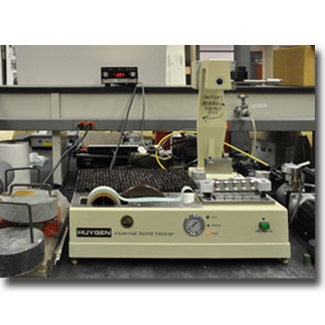

- RBI developed Torsion pendulum for out-of-plane shear rigidity measurment of combined board

- ECT Creep Analyzer

- RBI Crack Angle Tester

Box Testing

- Programmable High Humidity Walk-In Chamber

- BCT Creep Stations Inside Walk-In Chamber

- Box Compression Tester

- Concora Flat Crush Tester

How to Request Testing

- Send e-mail to jjl3@gatech.edu with details regarding the nature of the request, the tests required and the problem or issue that is to be resolved. Provide billing contact name and address.

- Samples via courier (UPS, FedEx, DHL, etc.) may be sent to the attention of:

Jonathan Jean-Louis

RBI at Georgia Tech

500 10th St. NW

Atlanta, GA. 30318-5794

If sending by U.S. mail replace the ZIP code with 30332-0620 - A Purchase Order for an amount to cover the costs for the requested testing is required.

Georgia Institute of Technology

Bursar’s Office/A/C Receivable

225 North Avenue, NW

Lyman Hall, Suite #111

Atlanta, GA 30332-0257

A copy of the Purchase Order sent via fax to 404-894-4778 is requested. - The sender should have the name of the appropriate RBI contact and phone number on their invoices/P.Os

- Receipt of samples coupled with e-mail detailing testing requirements and any background information initiates the generation of an internal project and officially starts the project.

- The work request is queued with others in order of time of receipt of samples. Work requests may be expedited under special circumstances.

- A report will be issued within the agreed turnaround time.

- Bills are sent separately by mail through the GT accounting system.

Pricing Policy

Paper Physical Testing Services are provided on a non-profit basis. Accordingly, the rates have been set through Georgia Tech's Cost Accounting analysis to recover operational costs, labor and materials consistent with Georgia Tech policy.

Informal estimates are issued upon client request. A typical billing for some test measurements on several samples is usually in the range of a few hundred to two thousand dollars. Final billing is based on the total time spent per contract per person.

A purchase order number is requested prior to commencement of testing.

For estimation purposes only:

Clients may consider that one test on one sample which may consist of several repeated measurements is in the order of $70.

For specific pricing contact jjl3@gatech.edu

PAPER, BOARD, AND BOX CONTACT

Jonathan Jean-Louis

Mechanical Technician II

Materials Institute

jjl3@gatech.edu

Paper Testing Equipment

RBI Developed Out-of-plane Ultrasonic |

Tear Testing in Progress |

RBI Developed Programmable Robotic Arm |

Emveco Stylus, Emveco Caliper and |

Optical Properties Measuring Instruments: |

Hygroexpansimiter for CD Profiles of |

Physical Properties Testing Instruments: |

Compression Tester for ECT Pin Adhesion |

RBI Developed General Use Robotic Arm for |

Taber Bending Stiffness, Parker Print-Surf |

Instron Test Frame for Generalized |

RBI Developed Variable Humidity |

Tensile Tester |

Video Formation Tester |

2 Point Bending Stiffness Tester |

Variable Environmental Chambers |

Taber Abrasion Tester |

L&W Densometer |

RBI Developed Torsion Pendulum |

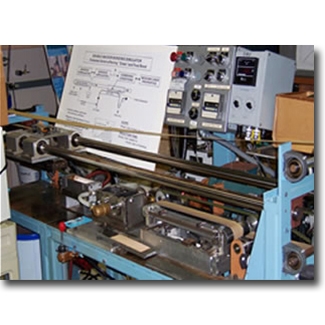

Double Backer Simulator |

Mullen for Corrugated Board |

Billerud Cutter for T 839 ECT |

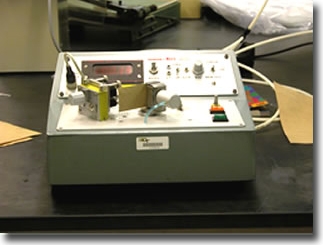

Honshu AR&PA Score Crack Tester |

Crush Tester with T 839 Fixtures |

4 Point Bending Stiffness Tester |

ECT Creep Analyzer |

RBI Crack Angle Tester |

Programmable High Humidity Walk-In |

BCT Creep Stations Inside Walk-In Chamber |

Box Compression Tester |

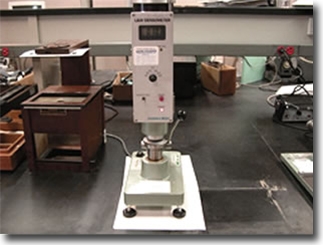

Out-of-plane/In-plane Ultrasonic Tester |

Handle-O-Meter "Handle" or Hand- |

Scott Bond Tester |

Amontons II ISO Method Friction Tester |

Zero Span Tester |

Sutherland Rub Tester |

Paper Mullen Tester |

Surface Resistivity |

Optical Moire Shadowgraphy |

Precision Grinder |

Computerized Oven for Moisture Solids |

Bendtsen and Sheffield Air Leak Method |

Hot Coefficient of Friction (HCOF) tester |

Cycling Paper Bag Handle Tester |

Frazier Air Permeability |

Corrugated Board Puncture T 803 (GE) |

Vapo-meter Cups Set-up for Moisture Vapor |

ZD Tensile Tester |