High Tech Makers

Jun 01, 2022 — Atlanta, GA

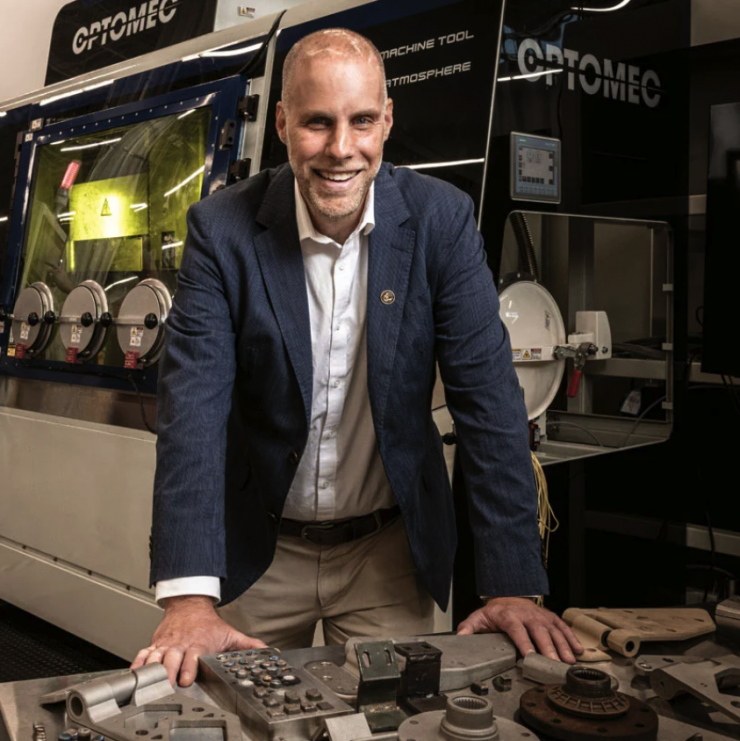

Harnessing Automation: John Morehouse, director of the Georgia Center of Innovation for Manufacturing at the Georgia Department of Economic Development, with a laser cutter at Georgia Tech that produced a variety of parts Photo: Kevin Garrett

Georgia is a place where people know how to make things. Consider that the parts holding rockets together as they blast into space are made in Dodge County. Carbice in Atlanta produces thermal tape for satellites. And Saft America in Valdosta makes advanced batteries that power airplanes, satellites and race cars.

Manufacturing of all types is soaring in the state, with over 11,000 companies employing an estimated 393,500 workers in 2021 – about 9% of Georgia’s workforce. Approximately three-quarters are production workers.

Today’s manufacturing is clearly not the old assembly line. Software and robots operated by highly trained technicians are driving America’s – and Georgia’s – maker resurgence. Even traditionally low-tech operations such as poultry plants are incorporating technology and robotics to automate dirty or dangerous jobs that are hard to fill.

Companies employing these advanced manufacturing practices had a total output of nearly $62 billion in 2019, representing approximately 10% of Georgia’s Gross State Product, according to National Association of Manufacturers (NAM) data.

Georgia has a lot going for it as a rising star in advanced manufacturing. Its reputation as the best state to do business is the result of a host of assets for companies looking to relocate and grow, according to John Morehouse, director of the Georgia Center of Innovation for Manufacturing at the Georgia Department of Economic Development (GDEcD). These assets include a pro-business climate, a trained workforce and a strategic location that allows companies to reach 80% of the U.S. market via truck, rail or plane. And the Port of Savannah is a gateway to (and from) the world.

One of the biggest draws is Georgia Quick Start, the nation’s No. 1 workforce training program that has provided customized training for more than 1 million workers. Another is the increasing flow of venture capital to the region.

Manufacturers are “recognizing this is where there’s a lot of value, and value is what they’re seeking,” says John Avery, director of the Advanced Technology Development Center (ATDC) at Georgia Tech.

Process Control

Maintaining a technological edge doesn’t come cheap. Southwire Company, a maker of wire and cable, is in the midst of a $1 billion investment that is “putting a lot of money into our factories, making a difference for our customers and adding capacity,” says CEO Rich Stinson.

While the process of making wire and cable has changed little over the years, the technology has advanced.

“What has changed is the equipment and the control of the process to make wire and cable,” explains Southwire Senior Vice President William Berry. “We’ve developed better control of motors, better products such as servo motors [that rotate machine parts with high efficiency].”

To grow manufacturing, the state is channeling resources into helping companies get started and improve their processes and technology. GDEcD’s innovation center has “teams that work in agricultural technology, energy technology, information technology, logistics, manufacturing, in aerospace,” says Morehouse. “We talk to them about what their challenges are to growth, and then connect them to the right resources in the state, whether that be an expert in academia, or other companies, or government agencies.”

The center can gear up to assist an entrepreneur with a new product idea or a large company with a production-line challenge.

New Industrial Revolution

The state, along with its agencies and educational institutions, has been pushing adoption of Manufacturing 4.0 (or Industry 4.0), which is dramatically changing the ways companies improve, manufacture and distribute products. New technologies like the Internet of Things (IoT), cloud computing and artificial intelligence (AI) are being integrated into operations.

Georgia Institute of Technology has been at the forefront of research and development in this area. Its Advanced Manufacturing Pilot Facility (AMPF) is a 20,000-square-foot, reconfigurable R&D facility in Midtown Atlanta that provides space for industrial, academic and government agencies to develop innovative manufacturing projects. It also serves as a teaching laboratory for Tech graduate students.

Made possible by a $3 million donation from the Delta Air Lines Foundation, AMPF is a flexible facility that can house all kinds of advanced manufacturing innovation projects, including industrial robotics and additive, hybrid, composite and digital manufacturing.

Companies use the space to test new designs and get feedback about new ways of producing products, according to Aaron Stebner, associate professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech, who is working on research integrating data informatics and machine learning for development of new manufacturing processes.

The state is committed to helping Georgia companies acquire and develop such advanced technologies to increase efficiency and competitiveness. As part of this effort, Georgia Tech launched the Georgia Manufacturing 4.0 Consortium to work with businesses in defense and related industries. The Georgia Manufacturing 4.0 initiative “is about helping Georgia manufacturers adopt Industry 4.0 technologies. There’s a special emphasis on small manufacturers who may be overwhelmed about the latest software they should buy, or don’t even have time to think about how to put a sensor on a machine to help with uptime,” says Stebner. “Through those programs, we can actually provide them assistance with workforce training, as well as innovate with them.”

Gulfstream, for example, equips workers with wearable devices to provide remote step-by-step instructions in situations where a supervisor is not on hand, says Stebner. Augmented intelligence can provide that supervision and continuous reminders to the employee.

“The human workforce is going to move to higher value-added activities, as they always have, whether it’s in agriculture, whether it’s in manufacturing today, and mechanization or automation back in the day,” explains Shreyes Melkote, a mechanical engineering professor who is executive director of the Novelis Innovation Hub at Georgia Tech. The partnership between Tech and the aluminum manufacturer and recycler focuses on basic and applied research related to sustainable processes.

Leading-edge Applications

Data is a key to adding efficiency to manufacturing operations. When ProcessMiner opened for business in 2014, its original goal was to optimize manufacturing processes for the pulp and paper industry.

Today, its platform predicts problems in real time using AI within the manufacturing process for companies in the pulp, paper and plastics industries. Pilot projects are underway for water treatment and energy sectors.

“We decided to go ahead and take on the challenge of solving this problem, not for one specific industry, but for manufacturing,” says Kamran Paynabar, co-founder and chief science officer at ProcessMiner.

The company’s focus is “leveraging AI, data science, machine learning, as well as domain knowledge for improving continuous manufacturing systems,” explains Paynabar. It can predict the quality of the product coming off the assembly line by collecting and processing data using machine learning and other technologies.

“Another thing that we really wanted to include in our offering and platform was the combined integration of domain knowledge and process experience plus data analysis to make sure that the solution that we provide actually works for the manufacturing system,” says co-founder and CEO Karim Pourak.

Lumber might seem like a simple business, but Rayonier Advanced Materials is developing decidedly high-tech applications for wood and its byproducts, such as purified cellulose. These substances are used in products that require absorbent materials like baby diapers and adult incontinence products. They’re also used in plastics, run-flat tires, sausage casings, timed-release pharmaceuticals and even LCD screens, according to Larissa Fenn, director of research and development into new high-purity cellulose (HPC) products at Rayonier’s Marketing and Research Center.

One recent project involved the use of wood byproducts to create prebiotics, or the food that fosters the growth of good bacteria in animals. Rayonier partnered with the University of Georgia’s poultry science department to test a product in chicken that was derived from wood extraction processes. “We wanted to see how it would perform in increasing their gut health and helping them to be resistant to disease,” Fenn says.

From Lab to Factory

The state is also a good place for new companies to get up and running.

Carbice is an Atlanta-based start-up company dedicated to designing, developing and producing a unique thermal material to remove heat from electronic devices. It produces thermal tape that can be used in satellites, and the growing company needed assistance to take its manufacturing operations to scale.

Carbice spun out of a lab at Georgia Tech to address a long-standing problem within the space industry of how to control heat generated by satellite circuit boards. It is a prime example of academic research that has evolved into a growing company with a valuable product.

“It’s one thing to be able to do lab-scale demonstrations of technology, but I focused on how do you make the material so that it can be scaled up for manufacturing,” says CEO Baratunde Cola. “Each of these satellites has about 50,000 square inches of thermal glue that they use to put on all the different electronic boxes. And the problem with it is that that glue is a very challenging manufacturing process.”

The company created a first-of-its-kind Space Pad that can adhere to the heat source on a satellite or other device. “Then you can easily take it off and stick it on. It takes a process that used to take three weeks and turns it into a three-minute process,” says Cola.

This is a material that will “replace things like thermal grease and thermal paste or graphite pads and ultimately simplify manufacturing,” says Cola. “It will improve performance across space, power trains in electric vehicles, semiconductor manufacturing, data centers and cloud computing, graphics cards and high-performance gaming.”

Technologies such as 3D printing enable companies to produce products that can be geared to customers in ways that were not possible in the past.

The Atlanta Drone Group is using advanced manufacturing processes to build its unmanned aircraft for “public safety from the ground up,” says CEO Matt Sloane. The company just released a new drone that can be configured to carry different kinds of payloads depending on the need of the individual agency, he says.

“We’ve done a lot of 3D printing of prototype parts, and in some cases, production parts are going to be 3D-printed,” says Sloane. “We’ve done a lot of 3D scanning, looking at the various sensors and scanning them so that we can integrate them into the design. And then we’re using cutting-edge carbon fiber lay-up [lamination] methods, that you typically see in [Formula One] racing rather than traditional drone manufacturing.”

Finding a Better Way

One of the biggest advanced manufacturing sectors is machining. This precision prototyping and manufacturing process creates parts that go into a wide range of products from farm equipment to airplanes.

Eastman’s Kencoa Aerospace, a supplier of multi-axis precision-machined and sheet metal-fabricated components, serves a customer list that includes Lockheed Martin, Gulfstream Aerospace and Boeing, which is constructing NASA’s Space Launch System – the most powerful rocket ever built.

Aerotech Machining is part of a growing manufacturing sector springing up in Chatham County near the Port of Savannah. The firm opened decades ago to serve the aerospace, agricultural, power generation and rail industries. With the aid of CNC (computer numerical control) machine tools, the company designs and produces parts using preprogrammed software and code to control the movement of production equipment. Aerotech can fashion parts using detailed specs as well as create designs to meet a specific use.

“They may come to us with a need, not quite knowing what the part should look like, and we would design and give them a 3D rendering of the part for their approval,” says Aerotech President Joey Jones. “We would make them a prototype. If they accept the prototype, then we will send the part off into production and make them however many pieces they need – from two to 200, or a lot more than that.”

Advanced manufacturing companies like these are driven by the need for efficiency and the elimination of waste from production methods. Many companies have turned to production methods such as lean manufacturing to reduce process inefficiencies. Automation and other technologies are now also decreasing process times and costs.

“We started our lean journey in 2003 and so we’re working to eliminate waste in all areas of the business,” says Brandyn Chapman, CEO of PHX Holdings, which owns Phoenix Stamping Group. The company makes sheet metal and rod component parts. “We’ve utilized technology as another tool to assist to that end. It’s one way we’ve implemented an ERP [enterprise resource planning] system and then utilized that to streamline and automate specific functions through the use of information technology.”

New battery and electric-vehicle parts makers have gotten a lot of press lately in Georgia but one long-time corporate citizen is Saft America. A wholly owned subsidiary of France’s TotalEnergies, the company specializes in advanced technology battery solutions for industry. Its products are in everything from satellites to airplanes where reliability is a must. More than 500 batteries are in space “and we’ve been there since 1966, which I think makes a pretty big statement,” says Kirk Rosenlund, general manager at Saft America.

Across the state, advanced manufacturing is growing as the national economy expands and increasingly companies realize that the best place to make things is right here in Georgia.

This article originally appeared in the June 2022 issue of Georgia Trend.

Written by RANDY SOUTHERLAND

Walter Rich

A Story Of Forgotten Hanji, Korean Traditional Paper

Dr. Oh-Kyu Lee will share his experience in rediscovering how to make certain types of Korean traditional paper called Hanji. In the past, there were more than two hundreds varieties of Hanji, which varied depending on source materials, size, usage, etc. Only a few of them are still being produced in Korea today. The topic of Dr. Lee’s talk will focus on two types of Korean traditional paper, named Taeji and Siji. This work has been done by his group at the National Institute of Forest Service in Korea.

Technology Licensing Feature: Using Capillary Foams to Recover Spilled Oil

May 02, 2022 — Atlanta, GA

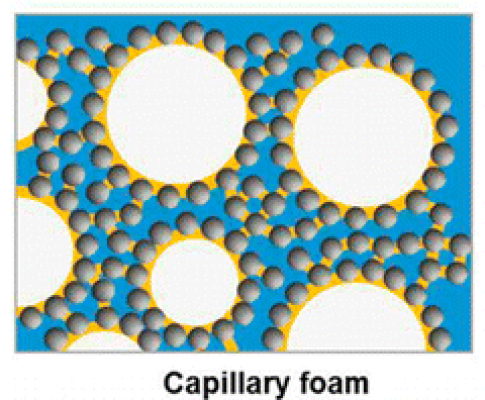

Capillary foam

Georgia Tech inventors (Carson Meredith, Sven Holger Behrens, and Yi Zhang) have identified a method that utilizes surfactant-free, oil-tolerant capillary foams consisting of a combination of colloidal particles, oil, water, and gas. This method allows the recovery of off-shore oil spills that allows the subsequent recovery of the oil.

A collection device allows the infusion of air and the addition of colloidal particles. As the oil and water is processed through the device, a capillary foam gel is formed. The foam cells are stabilized synergistically by oil and (readily available, inexpensive) solid particles of appropriate wettability, without the need for any surfactants. Networks of oil-bridged solid particles inside the aqueous lamella of capillary foams confer upon the foam a tunable viscosity. The accumulated foam can be mechanically removed from the water surface (either by skimming, scooping, or pumping), and transported to another location where a de-foaming agent can be added to “decompose” the capillary foam into its component parts (water, recovered oil, and stabilizing particles).

Read Full Feature

Walter Rich

ChBE Professors Win Curriculum Innovation Award

May 02, 2022 — Atlanta, GA

Carson Meredith, Fani Boukouvala, and Martha Grover

Five faculty members in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE) shared the 2022 Curriculum Innovation Award presented by Tech’s Center for Teaching and Learning for the development of the Online Graduate Certificate in Data Science for the Chemical Industry (DSCI).

The winning faculty team included ChBE Professors Fani Boukouvala, Martha Grover, Andrew J. Medford, Carson Meredith, and David Sholl. This award includes a prize of $3,000, which they will share.

Launched in Fall 2020, the Online Graduate Certificate in DSCI is the only credential of its kind, preparing chemical engineers with the skills and expertise they need for the future of work.

As chemical, energy, and manufacturing companies worldwide race to take advantage of big data trends in what has become known as Industry 4.0, a key need for that sector is strong domain knowledge in chemical engineering coupled with skills in data science.

Zak Kuiper, data scientist for the Mosaic Company, said that the DSCI program is “the first to the table in answering a need which most of the chemical industry is just now realizing they have. It has allowed me to develop as a professional significantly quicker than I would have otherwise and has shaped how our organization has focused on the area of Data Science.”

Designed to be completed in one-to-two years, the certificate (offered in partnership with Georgia Tech Professional Education) consists of six hours of core courses (Data Analytics for Chemical Engineers and Data-driven Process Systems Engineering) on foundational data science methods, with a strong emphasis on applications in the chemical process industry. An additional six hours of electives provide the opportunity to focus on a specific area of interest and can be selected from within Georgia Tech’s prestigious online master's degree in analytics.

Companies including 3M and Dow Chemical have partnered with Georgia Tech to enroll their employees in the DSCI program to provide skills in the emerging field of data science and data analytics. At the same time, the courses are also available to resident Georgia Tech graduate students, as well as senior undergraduate students, who take the courses for credit toward their degrees.

Writing in support of DSCI's nomination for the Curriculum Innovation Award, 3M officials Cristina Thomas and Chris Jacobs, said, "We value this program so highly that 3M Corporate R&D has granted full ‘internal’ scholarships to 11 employees to date and plan to award more for the coming school year with full support from their managers."

The certificate is built upon two core courses (Data Analytics for Chemical Engineers, and Data-driven Process Systems Engineering)

Christopher Jones, the John F. Brock III School Chair of ChBE, said the certificate program is “not only a fabulous educational innovation, it is also a crucial thought-leadership platform, one where we are far ahead of the curve, offering programmatic innovations that other institutions are just starting to imagine. I am tremendously proud of our DSCI team – we are fortunate to have them as members of our community.”

Jackson Dean, BS ChBE 2021, a data science associate (pharmaceutical supply chain) for GlaxoSmithKline, said, “I found success in these courses due to the thoughtful design of each course, which fostered a high level of engagement….The combination of lecture videos and instructor-created code demo notebooks to act as the primary course material meant that I had multiple ways of learning the material.”

Dean added: “The curriculum of this certificate program directly addresses this need of creating data-fluent chemical engineers – teaching skills such as data management/cleaning, building machine learning models, and data visualization.”

The application deadline for Fall 2022 is May 1, 2022. Learn more.

Walter Rich

Marilyn Brown Tapped as First Woman to Receive Class of 1934 Distinguished Professor Award

Apr 29, 2022 — Atlanta, GA

Marilyn Brown, Regents' and Brook Byers Professor of Sustainable Systems in the School of Public Policy, at the Clough Building rooftop solar panels.

Marilyn Brown is a world-leading expert on renewable energy and energy efficiency, a transformative intellectual thinker, and one of the founders of the field of energy and climate policy.

Her research has shaped energy policy in the U.S. and globally. Over the past two years, she has been tapped for several prestigious honors, including being elected to both the U.S. National Academy of Engineering and the National Academy of Sciences, and receiving the 2021 World Citizen Prize in Environmental Performance. Now, she is the first woman to receive the Georgia Tech Class of 1934 Distinguished Professor Award in the 38 years of its existence. It is the highest honor given to a Georgia Tech professor. The award is presented to a professor who has made significant, long-term contributions to teaching, research, and public service.

Brown is the Regents and Brook Byers Professor of Sustainable Systems in the School of Public Policy. She joined Georgia Tech after 22 years at Oak Ridge National Laboratory, where she directed several national climate change mitigation studies and became a leader in the analysis and interpretation of energy futures.

At Oak Ridge National Laboratory, she was the joint highest-ranking female manager. Brown was attracted to Georgia Tech after working with a high-level group of scientists from Oak Ridge, the Imperial College of London, and Georgia Tech on a project involving next-generation energy, including advanced broadband. “I really liked the people from Tech who I worked with on the project,” said Brown. “They had a can-do attitude. At other universities, they might say, ‘That can’t be done.’ The people from Georgia Tech said, ‘We’ll find a way.’” In 2006, she was encouraged to apply for the position of — and was chosen as — a full professor in the School of Public Policy in Georgia Tech’s Ivan Allen College of Liberal Arts.

Throughout her career, Brown has been known for her transdisciplinary, action-based research and linking behavior to policy. “I started my career in the physical sciences at Rutgers. “From the beginning, I brought sciences into my work and have been quantitative. It has given me the ability to span sciences and related fields,” said Brown. “I tell my students they have to be quantitative in math and the physical sciences to be effective in energy.”

The focus of her research has been on the clean energy transition — bridging engineering, social and behavioral sciences, and policy studies to advance the design, adoption, and diffusion of clean energy technologies and policies. She is particularly interested in energy disparities and work to strengthen energy infrastructure, especially in areas of financial need. “It is all about the diffusion of innovation to the benefit of all,” she said.

Drawdown Georgia

Brown also leads the research program Drawdown Georgia, which she helped to create with the inspiration and funding of the Ray C. Anderson Foundation. Georgia Tech alumnus Ray C. Anderson was founder and chair of Interface Inc., and a pioneer in sustainability.

Drawdown Georgia was created and is being conducted in partnership with Emory University, the University of Georgia, and Georgia State University, as well as the Southface Institute, the Partnership for Southern Equity, and Greenlink Analytics.

Drawdown Georgia has identified a roadmap to significantly cut Georgia’s greenhouse gas emissions and achieve carbon neutrality. The Drawdown Georgia study, localized for Georgia’s urban and rural areas, was published in the Proceedings of the National Academy of Sciences in 2021. The plan identified technology and practices that could resonate with individuals, towns, and corporations throughout the state, including ways to bring more clean energy resources and technologies to rural Georgia and help people use limited resources more efficiently.

Through collaboration with the Scheller College of Business, 25 Georgia CEOs from throughout the state agreed to join Drawdown Georgia. The project includes a dashboard of emissions by Georgia’s 159 counties, tracked monthly. The next step will be to track implementation of the 20 solutions in the plan, measuring investments by counties, and the use of electric vehicles, rooftop solar systems, alternative transportation, recycling, composting, afforestation, and silvopasture — the integration of trees and livestock operations on the same land.

Sustainability as a Way of Life

When asked what she wishes people knew about sustainability, Brown said, “Sustainable technologies and behaviors are not costly. They can be good for your pocketbook. Consider the home refrigerator. Twenty-five years ago, it consumed 2,000 kilowatt hours a year. Today it requires less than 600 kWh, and they don’t cost any more than they used to. People just have to be smart about what they choose and pay attention to cradle-to-grave resource issues.”

Brown also lives her values. At her home, she grows vegetables and composts, has rooftop solar, a Tesla Powerwall battery, and uses heat pumps for water heating, air conditioning, and heat. Her family has an energy focus. Her husband, Frank Southworth, is an adjunct professor in the School of Civil and Environmental Engineering at Tech, and an accomplished transportation planner. Their daughter, Katie Southworth, is an attorney with Southface Energy Institute.

Working with Students

Brown created and co-leads the Climate and Energy Policy Lab in the School of Public Policy at Tech. She developed the Master of Sustainable Energy and Environmental Management degree. She has advised 19 Ph.D. students, many of whom have gone on to leading roles in government agencies, academia, and industry.

She is known as an excellent mentor, communicator, and educator, inside and outside of the classroom. She challenges students to expand their knowledge and excel in their project work while developing their confidence and leadership skills. She has been described as generous with her time in providing students with guidance on professional development. As she was one of very few women in her field when she began her career, she has been purposeful about mentoring women.

Background

Brown earned her Bachelor of Arts degree in political science from Rutgers University, and a Master of Regional Planning degree from the University of Massachusetts. She holds a Ph.D. from The Ohio State University in geography, with a minor in quantitative methods. Before joining Oak Ridge National Laboratory, she was an associate professor of geography at the University of Illinois, the first woman to earn tenure in geography there. Previously, she was a lecturer in the Department of Geography and Geology at Ohio Wesleyan University.

She has authored six books and more than 250 publications, and contributed to the United Nations 2007 Intergovernmental Panel on Climate Change (IPCC), a joint winner of the Nobel Peace Prize that year. Her work has had significant influence and visibility in the policy arena as evidenced by her impact on policies and programs, such as the Kyoto Protocol and the U.S. Department of Energy’s Weatherization Assistance Program, and briefings and testimonies before state legislative and regulatory bodies, committees of both the U.S. House of Representatives and Senate, and numerous international organizations.

Brown served two terms (2010-2017) as a presidential appointee and U.S. Senate-confirmed regulator on the board of directors of the Tennessee Valley Authority (TVA), the nation’s largest public power provider. At TVA, she contributed to reducing TVA’s CO2 emissions by 60% over a 15-year period. She also chaired for eight years the Nuclear Oversight Committee, which was responsible for bringing the most recent nuclear unit into commercial operation in the U.S., in 2016 at Watts Bar in Tennessee.

Reflecting her commitment to the role of demand-side management, Brown co-founded the Southeast Energy Efficiency Alliance (SEEA), chaired its board of directors for several years, hired its first executive director, and provided SEEA’s first office space at Georgia Tech.

Quotes from Colleagues and Former Students

“In her work, she conceptualizes the coevolution of technology and society, with an emphasis on the formation of a set of unsustainable systems for the provision of energy, food, mobility, water, and other areas — and the construction of new sustainable alternatives that may become the foundation for the formation of a new set of systems. However, rather than adhering to a narrow interpretation and application of geography and economics, her background, she uses sociotechnical insights to inform her research and sheds light on the complex processes of societal transformation needed for addressing the climate and biodiversity crises as well as steep inequalities. In short, she draws on science to make extremely compelling and insightful contributions to addressing contemporary challenges.”

Benjamin Sovacool

University Distinguished Professor of Business and Social Sciences – Aarhus University, Denmark

Professor of Energy Policy, Science Policy Research Unit – University of Sussex Business School, United Kingdom

“Dr. Brown’s contributions to the school and Institute extend beyond her own record to also include those of her students, who are excelling and driving important work both in and out of academia. Her students have founded startups in the explosive new climate tech field, lead energy and climate policy for major corporations like Google, work at multiple energy commissions at the state and federal level in regulatory staff roles, lead new areas of research in economics and policy in research centers across the world, and recently, one of her students was appointed as a deputy assistant secretary at the U.S. Department of Energy. I don’t believe that it is a coincidence that this group of exceptional people all happened to emerge from the same lab at Georgia Tech. Dr. Brown played a formative role in helping develop the attitudes and thought processes that have enabled her students’ success and grown the influence of Georgia Tech around the globe.”

Matt Cox

CEO and Founder, Greenlink Analytics

“Marilyn challenges students to reflect on what can be done to show impact and relevance. She challenges students and collaborators to identify gaps in research that need to be addressed to advance science and discovery. Marilyn has had an exemplary career in teaching, research, and service, and her impact is significantly amplified by the hundreds of students and collaborators she has developed into the current and future generation of research and policy leaders and mentors.”

Melissa V. Lapsa

Building Technologies Program Manager

Energy Science and Technology Directorate

Oak Ridge National Laboratory

“Marilyn led by example as a Clean Energy and Education Empowerment (C3E) ambassador who sought to inspire the next generation of clean energy practitioners and researchers. I have always been impressed by the way Marilyn brought her intellectual acumen, strong moral compass, and sound judgement to bear on the deliberations and decision making with the wide range of different stakeholders involved in C3E. Moreover, Marilyn always made it a point to recognize the work of women researchers in academia and national laboratories in terms of the impact and importance of their contributions.”

Ellen Morris

Director, University Partnerships

NREL (a national laboratory of the U.S. Department of Energy)

“The regularly scheduled Friday meetings of students and faculty at Dr. Brown’s direction were among the most innovative and rigorous discussions of clean energy policy and economic analysis anywhere.”

“Through both her body of work and numerous former students who work at or with the [Georgia Public Service Commission], she has a major indirect influence on the direction of utility regulation in this state and around the country.”

Benjamin H. Deitchman

Utility Analyst, Georgia Public Service Commission

Georgia Tech, Ph.D. in Public Policy, 2014

This story originally appeared in the Georgia Tech News Center.

Patti Futrell

Faculty Communications Program Manager

Carbon Tracker Lets Georgians Monitor Emissions

Apr 15, 2022 — Atlanta, GA

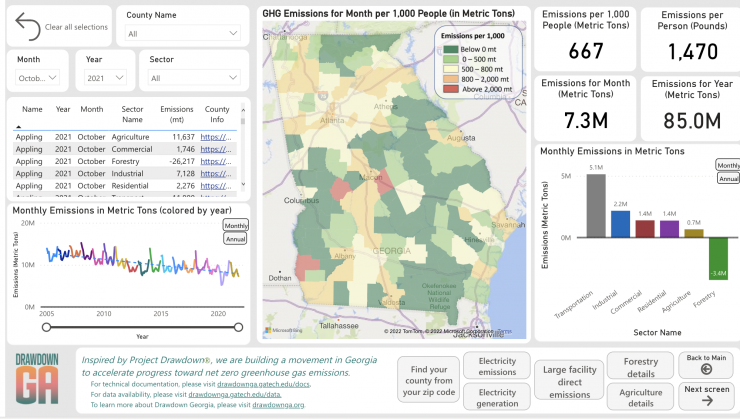

Georgians can now track where greenhouse gas emissions come from thanks to a tool that estimates those emissions at the state and county level.

Developed by Georgia Tech professors, the interactive map allows users to filter publicly available greenhouse gas estimates by county, month, year, and energy sector. Users can specify whether the emissions come from transportation, agriculture, commercial, forestry, residential, or industrial sources and counter with how much carbon is absorbed by trees and soils.

“The purpose of the tracker is to bring technology to bear on climate solutions,” said William Drummond, an associate professor in the School of City & Regional Planning and the lead behind the tracker. “This is the first time there has been effort to downscale emissions to the local level in a dynamic way we can update every month.”

The initiative is part of a trifold effort in Drawdown Georgia, a Ray C. Anderson Foundation–funded project across state universities to decrease reliance on carbon inspired by the national program Project Drawdown. As the first stage, the tracker enables Georgians to understand how the state contributes to emissions. Next, the Scheller College of Business will develop a business compact study to assess the economic impact of less carbon, and then the School of Public Policy will lead solutions activation. The tracker ties everything together by letting researchers measure how effective all the efforts are combined.

Ultimately, the researchers hope to inspire everyday Georgians to get involved in combatting climate change. With the public’s familiarity with Covid-19 case trackers, Drummond believes the tracker is accessible to most users, from regular citizens unsure how to help the environment to high school science students.

“This tracker is designed to be a catalyst for a climate movement across the state of Georgia, so it's important that we include ordinary citizens, advocacy groups, and businesses as partners in working toward climate solutions in Georgia,” Drummond said.

The researchers expect the carbon tracker will grow beyond Georgia. The tool is written in the common coding language R, so other states can replicate it. They also hope to track many other climate elements in the next few years.

“We'll progress as the technologies and markets evolve, and will soon turn to where the solutions are — not just where are the emissions are,” said Marilyn Brown, a Regents' and Brook Byers Professor of Sustainable Systems in the School of Public Policy. “We’re going to tie it all together, and it's all going to be facilitated by this geospatial tracking.”

Tess Malone, Research Writer/Editor

Sholl Appointed to New Department of Energy Office

Mar 11, 2022 — Atlanta, GA

Professor Sholl is the former chair of Georgia Tech’s School of Chemical and Biomolecular Engineering, and he is a faculty member of the Renewable Bioproducts Institute.

David Sholl has been appointed as a senior portfolio advisor in the Department of Energy's new Office for Clean Energy Demonstrations (OCED). OCED has been allocated over $20B through the Infrastructure Investment and Jobs Act for large-scale demonstrations in clean hydrogen production, carbon capture, energy storage, and advanced nuclear reactors. In this half-time position, Professor Sholl will advise OCED's Portfolio Management group as they coordinate OCED's strategy for these demonstrations.

Professor Sholl is the former chair of Georgia Tech’s School of Chemical and Biomolecular Engineering, and he is a faculty member of the Renewable Bioproducts Institute.

More information about OCED is available here: https://www.aip.org/fyi/2022/doe-stands-clean-technology-demonstration-office#:~:text=The%20Department%20of%20Energy%20announced,Infrastructure%20Investment%20and%20Jobs%20Act.

Link to the Sholl Research Group.

Walter Rich

BioMADE Supports Georgia Tech Researchers to Strengthen American Competitiveness in the Bioindustrial Manufacturing Industry

Mar 03, 2022 — Atlanta, GA

BioMADE Supports Georgia Tech Researchers to Strengthen American Competitiveness in the Bioindustrial Manufacturing Industry.

BioMADE, a Manufacturing Innovation Institute sponsored by the U.S. Department of Defense, has recently funded a research project at Georgia Tech entitled ‘Stress Testing Supply Chains and their Ecosystems for Levels of Trust, Security, Resilience, Agility, and Competitiveness’. Headed by faculty members Chip White, Kevin Wang, and Ben Wang, this project will design, develop, and validate a simulation platform to stress test end-to-end bioindustrial manufacturing facilities and supply chains resiliency over multiple risks with the intent of strengthening American competitiveness and creating more robust and resilient supply chains.

Bioindustrial manufacturing uses living organisms such as bacteria, yeast, and algae, to make new products or replacements for current products that are more sustainable and environmentally friendly than current processes.

The simulation platform will be a customizable decision support system that will target disruptions that may be faced by supply chains in the biomanufacturing industry. Understanding the impact on performance of each disruption can lead to supply chain design and operations changes that will produce improved levels of supply chain performance when disruptions occur.

“Although this project is initially focused on supply chain productivity at the product or firm level, it is also intended to provide insight into how investments in the bioindustrial ecosystem can improve bioindustrial supply chain supply chain performance while ensuring the Nation’s public health, defense, and economic security,” said White.

Understanding how performance at the product- and firm-level throughout the industry contributes to industry ecosystem performance, and vice versa, will help to inform both future product- and firm-level supply chain design and the development of the Nation’s bioindustrial ecosystem.

Chip White holds the Schneider National Chair of Transportation and Logistics and is a professor in the Stewart School of Industrial and Systems Engineering. Kan Wang, Ph.D., is a senior research engineer in the Georgia Tech Manufacturing Institute (GTMI). Ben Wang is executive director of GTMI, holds the Gwaltney Chair in Manufacturing Systems and is a professor in both the Stewart School of Industrial and Systems Engineering and the School of Materials Science and Engineering.

Walter Rich

Atlanta Company Converts Hard-to-recycle Plastics into Fuel

Feb 22, 2022 — Atlanta, GA

Carsten Sievers is an associate professor in the School of Chemical and Biomolecular Engineering at the Georgia Institute of Technology.

ATLANTA — An Atlanta company is making the world a cleaner place with new technology.

Nexus Circular in southwest Atlanta has converted millions of pounds of landfill-bound plastics back into oil and wax to be used for new plastics production.

This is important because about 27 million tons of plastic went into landfills last year, according to the U.S. Environmental Protection Agency.

This potentially harmful garbage takes hundreds of years to break down.

Many residents place unrecyclable products into single-stream recycling bins, including plastic bags and food film, that are too expensive or complex to recycle, according to Cherokee County recycling manager Troy Brazie.

Brazie said about 20% of what he receives from customers at his facility ends up in a landfill.

“There is the thought process that well, it’s plastic so it’s going to be recycled because I’m putting it in recycling,” Brazie said.

That hard-to-recycle plastic is exactly what Nexus founder Jeff Gold wants. In his 120,000 square foot plant, he converts 50 tons of plastics to fuel a day.

That oil and wax are sold to partners including Shell and Chevron Philips to make new plastic.

Last year Nexus received a major investment from Cox Enterprises to get the operation up to scale.

“The amount of material (we’ve) diverted, almost 4 million pounds of plastic that would otherwise be going to the landfill, back into useful valuable products that they themselves are recycled circular processes,” Gold said.

Georgia Institute of Technology professor Carsten Sievers said Nexus is one of a handful of companies in the U.S. and Europe using this type of molecular recycling.

He said converting it back into the building blocks of new plastic is a vast improvement from sitting in a landfill.

Sievers said potentially dangerous plastic breaks down into our oceans and water supply.

“I think managing our environmental footprint is generally something we should all desire,” he said.

By Dave Huddleston, WSB-TV

Carsten Sievers is an associate professor and Thomas J. Pierce Jr. Faculty Fellow in the School of Chemical and Biomolecular Engineering at the Georgia Institute of Technology.

Walter Rich

Nearly Two-Thirds of Georgians Support Immediate Action on Climate, Survey Shows

Feb 21, 2022 — Atlanta, GA

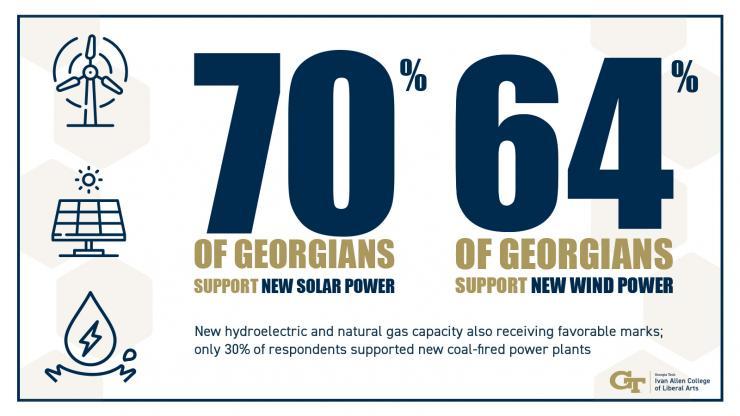

A majority of Georgia residents strongly support new solar and wind power capacity over new coal-fired plants and believe the state should set a carbon emissions reduction goal, according to a new survey conducted for researchers at Georgia Tech and the University of Georgia.

The survey, conducted by polling firm Dynata, found that 60% of Georgia residents back the creation of a state carbon emissions reduction goal. That includes 74% of Democrats and Democratic-leaning independents, 52% of independents, and 45% of Republicans and Republican-leaning independents.

The poll also found that 70% of Georgians support new solar power and 64% support new wind power, with new hydroelectric and natural gas capacity also receiving relatively favorable marks.

The survey found only 30% of respondents supported new coal-fired power plants.

“This survey demonstrates that many Georgians across the political spectrum are in favor of green energy solutions that will benefit the state’s environment, create new jobs, and support our economy,” said Marilyn Brown, Regents Professor and Brook Byers Professor of Sustainable Systems in Georgia Tech’s School of Public Policy.

Cory Struthers, assistant professor in the School of Public and International Affairs at the University of Georgia, and Brown designed the survey with help from graduate students in Georgia Tech’s Climate and Energy Policy Lab (CEPL).

Brown and Struthers are affiliated with Drawdown Georgia, a project of the Ray C. Anderson Foundation, which provided funding to universities and stakeholders across Georgia to identify promising climate solutions for the state. The Foundation provided support for this survey, in addition to other activities to translate research into action, including the Drawdown Business Compact.

“This survey provides important new information about how people in Georgia feel about climate solutions,” said Blair Beasley, the Foundation’s director of climate strategies. “We are pleased to see that the results validate Georgians' support of many high-impact solutions that Drawdown Georgia has identified for their potential to reduce emissions in our state this decade.”

The Busbee Endowment at the University of Georgia and Georgia Tech’s Brook Byers Institute for Sustainable Systems also provided support for the survey.

Support for a Range of Climate Solutions

The survey of 1,788 Georgia residents was conducted online from Aug. 20, 2021, to Sept. 5, 2021.

All survey participants answered a set of common questions about their demographics, energy bills, knowledge of climate solutions, values, and more. The respondents were then divided into three groups, with participants in each answering additional questions that focused on one of three transformational climate solutions: rooftop solar, retrofitting, or electric vehicles.

The survey’s margin of error is plus or minus 2 percentage points for questions in the larger, common, sample and plus or minus 4 percentage points for those in the smaller sample.

Overall, 75% of Democrats, 55% of independents, and 49% of Republicans supported development of a climate resiliency plan for Georgia to prepare for the impacts of climate change.

When asked about new energy infrastructure, new solar panels and wind farms received 70% and 64% support, respectively. In contrast, 36% of those surveyed showed support for new nuclear power plants, somewhat higher than for new coal plants. Seventy-one percent of respondents favored energy efficiency strategies and smart-meter infrastructure.

Climate technologies that individuals can adopt at home were also well-viewed. A majority of respondents either already had residential energy-saving technologies or were interested in adopting them. The highest combined level of interest and adoption was for using LED lights at 93%, followed by efficient HVAC systems (80%), rooftop solar (59%), community solar (59%), and electric vehicles (55%).

Many respondents were also willing to support government funding for financial incentives to go green: 50% said they would support $5,000 rebates for electric vehicles, 55% said they would look favorably on up-front financing for heat pumps, and 64% said they would support a similar strategy for rooftop solar projects.

“These high-impact solutions have the potential to both reduce emissions and increase energy efficiency in Georgia,” Struthers said. “A cleaner, more efficient Georgia means increased air and environmental quality, job creation, and gains in public health.”

Survey Also Reveals Details of Energy Poverty, Low Energy Literacy

The survey findings also shed light on the prevalence of “energy poverty” in Georgia. A household is energy-poor when it spends more than 6% of its income on energy. The survey found that while households with incomes greater than $150,000 spent about 2% of their income on energy bills each month, households with incomes less than $20,000 spent, on average, between 14% and 21% of their monthly earnings on energy.

The survey also found low levels of literacy in regard to climate solutions, energy technology, and policy among respondents. Fewer than 35% of respondents knew the correct answer to questions related to energy and climate, including what energy sources are fossil fuels and the relative cost of operating electric and gasoline-powered vehicles. Only 4% of those surveyed correctly answered that solar panels generate energy in full sunlight, in the shade, and on rainy days.

“We want to use this data to continue to answer questions about the diffusion of, and support for, clean and equitable energy technology transition in Georgia,” Brown said. “How can this data help us overcome ambivalence toward clean energy and design programs that make the energy transition work for all Georgians, especially the most vulnerable? How can it help us to raise knowledge and awareness about the promise of high-impact climate solutions?”

A PowerPoint of the full findings can be downloaded from the CEPL website.

About Georgia Tech

The Georgia Institute of Technology, or Georgia Tech, is a top-10 public research university developing leaders who advance technology and improve the human condition.

The Institute offers business, computing, design, engineering, liberal arts, and sciences degrees. Its nearly 44,000 students, representing 50 states and 149 countries, study at the main campus in Atlanta, at campuses in France and China, and through distance and online learning.

As a leading technological university, Georgia Tech is an engine of economic development for Georgia, the Southeast, and the nation, conducting more than $1 billion in research annually for government, industry, and society.

The Ivan Allen College of Liberal Arts, home of the School of Public Policy, provides innovative, human-centered perspectives at the intersections of humanities, social sciences, arts, and STEM, developing leaders who advance technology and improve the human condition. Nearly 350 tenured, tenure-track, non-tenure track, and permanent research faculty, prepare students to be leaders capable of balancing a richly defined base of expertise with a well-grounded sense of responsibility. Our programs encompass traditional fields as well as unique and professional disciplines. Many of our faculty members engage in ground-breaking, interdisciplinary research to solve complex issues of the world.

About the University of Georgia

Chartered by the state of Georgia in 1785, the University of Georgia is the birthplace of public higher education in America. What began as a commitment to inspire the next generation grows stronger today through global research, hands-on learning, and extensive outreach. A top value in public higher education and research, the University of Georgia tackles some of the world’s grand challenges, from combating infectious diseases and creating a dependable food supply to advancing economic growth and strengthening cyber and global security.

As Georgia’s flagship institution, the university is recognized for its commitment to student excellence through an emphasis on rigorous learning experiences both inside and outside the classroom, including hands-on research and leadership opportunities. These experiences contribute to the university’s exceptional rates in retention, graduation, and career placement. Among public universities, the University of Georgia has been one of the nation’s top three producers of Rhodes Scholars over the past two decades. The university is also home to the Peabody Awards, the most prestigious prize in electronic media.

Since 2001, the School of Public and International Affairs has been dedicated to enhancing civic engagement, public leadership, scholarship on political institutions and policy, and effective governance. Now, more than ever, the nation and the world require scholars and students to focus their attention on the pressing policy and governance issues of the day. Guided by an award-winning teaching faculty and innovative research, the School offers critical training to future public servants and a deep understanding of national and international politics.

Michael Pearson

michael.pearson@iac.gatech.edu