Additive Manufacturing Startup Receives International Recognition

May 26, 2016 — Atlanta, GA

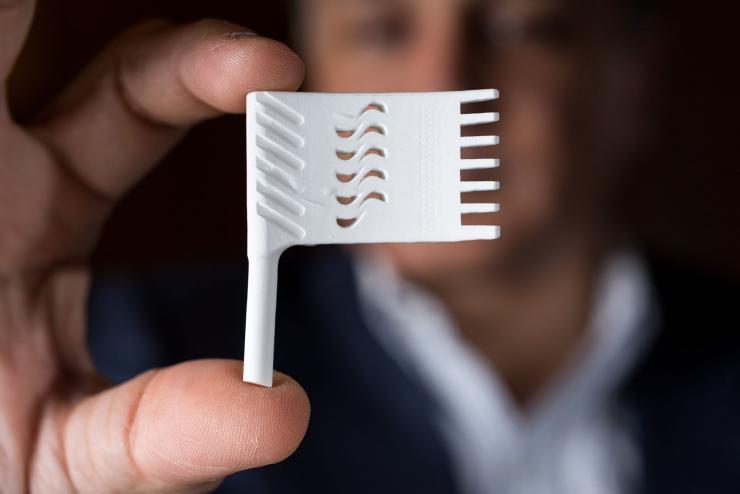

Suman Das, Morris M. Bryan, Jr. Chair in Mechanical Engineering for Advanced Manufacturing Systems and Professor, holds a piece made by the LAMP System CPT6060, a 3D printer used for fabricating ceramic cores and molds used in making aircraft parts.

A 3D printer based on technology developed at Georgia Tech was recently lauded by international industrial technology leaders for the device’s faster and less costly method of making ceramic cores and molds used in making aircraft parts.

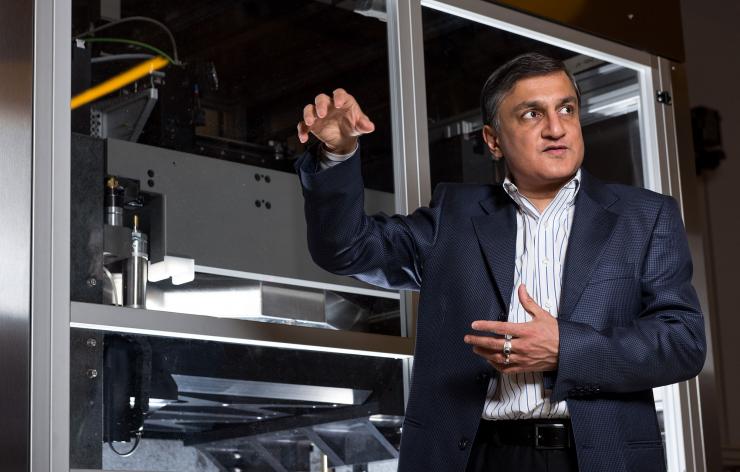

DDM Systems, a company formed by a Georgia Tech team led by Suman Das, a professor in the George W. Woodruff School of Mechanical Engineering, was one of five finalists and the only one from the United States nominated for a prestigious industrial award presented annually at the international industrial fair Hannover Messe.

Das’ team developed a machine that uses advanced 3D printing technology specifically designed to make ceramic cores and molds used by foundries to cast highly demanding and complex parts such as aircraft turbine engine components.

The machine, called the LAMP™ System CPT6060, makes the ceramic pieces directly from a computer-aided design file, drastically reducing the production time when compared with the traditional method of making castings.

The ceramic cores and molds are in great demand by manufacturers making precision components for a diverse group of applications, including aerospace, energy, biomedical and automotive industries. Traditionally, the process of making the molds involves numerous steps including injection molding a ceramic core, creating a wax model around the core, and using a ceramic slurry to slowly build a shell mold around the wax.

The LAMP machine circumvents that process by fabricating the mold directly from a digital design. In addition to the faster turnaround time, the new technique can reduce the cost of making the molds by as much as 65 percent for new component designs.

The development of LAMP technology began in 2007 with funding from the Defense Advanced Research Projects Agency (DARPA). In 2012, Das and John Halloran, a professor at the University of Michigan and Das’ co-principal investigator for the $6.3 million project, formed DDM Systems Inc. to help bring the technology to market.

The LAMP system works by converting a digital design into thousands of high-resolution images that the machine uses to build parts a single 100-micron layer at a time using a slurry mixture of photosensitive binder resin and ceramic particles.

The 3D printer is large enough to simultaneously build numerous parts during one session. Once the resin is removed from the molds, they are ready for use in casting.

Aside from its use in fabricating ceramic cores and molds for investment casting, the LAMP system is also capable of 3D printing a variety of other complex pieces from the ceramic slurry.

Das, who directs the Direct Digital Manufacturing Laboratory at Georgia Tech, called the environment at the institute crucial to supporting the development of the technology.

“The Georgia Tech Manufacturing Institute provided tremendous support,” Das said. “That allowed me to have the environment, the facilities, and the infrastructure to be able to do this kind of work – to be able to design and build these pieces of equipment and to really start to put all of these things together to a point where it wasn’t just a science project.”

The GTMI’s reputation for working closely with industrial firms to find innovations also leads to advancements such as LAMP being developed on campus.

“Every single day, someone from some industry is here on campus,” Das said. “Being able to interact with these kinds of people and getting to know what industry needs was extremely important. That doesn’t happen simply by people visiting. It happens when you’re embedded in an environment that encourages that, and is known for that.”

Das also relied on the Georgia Tech Integrated Programs for Startups (GT:IPS), which provides guidance for students and faculty aiming to launch start-up firms to translate discoveries made in labs on campus, as well as VentureLab, which helps create startup companies based on Georgia Tech research.

From its beginnings, the project exemplified Georgia Tech’s mission of using research and innovation to educate a host of students during their academic pursuits, Das said.

“The project played a critical role in the training of Master’s and Ph.D. students who participated in the incubation of a groundbreaking technology, a rare opportunity,” Das said. “And ultimately they all graduated and they’re having successful careers elsewhere. So it was a success story from that point as well.”

In addition to LAMP technology, DDM Systems is also commercializing a technology called Scanning Laser Epitaxy, which can be used to repair existing aircraft engine parts and build entirely new parts in the most demanding high-temperature alloys through additive manufacturing techniques. The company has licensed both technologies from Georgia Tech.

While Hannover Messe’s 2016 HERMES Award was given to another finalist, Das said the opportunity to showcase DDM’s technologies before an international audience represented an important milestone in the evolution of the company.

“Becoming the first US company to have received a top 5 nomination in the history of the award led to tremendous recognition, including a meeting with President Barack Obama and German Chancellor Angela Merkel, as well as other U.S. and German trade officials,” Das said.

Suman Das, Morris M. Bryan, Jr. Chair in Mechanical Engineering for Advanced Manufacturing Systems and Professor, stands in front of the LAMP System CPT6060, which makes ceramic cores and molds used in making aircraft parts.

Suman Das, Morris M. Bryan, Jr. Chair in Mechanical Engineering for Advanced Manufacturing Systems and Professor, joins President Barack Obama and German Chancellor Angela Merkel at the industrial trade fair Hannover Messe, where Das' company was honored for its LAMP System CPT6060, a 3D printer used for fabricating ceramic cores and molds used in making aircraft parts.

Research News