A Day’s Work at the RBI Chemical Analysis Lab

Nov 09, 2023 — Atlanta, GA

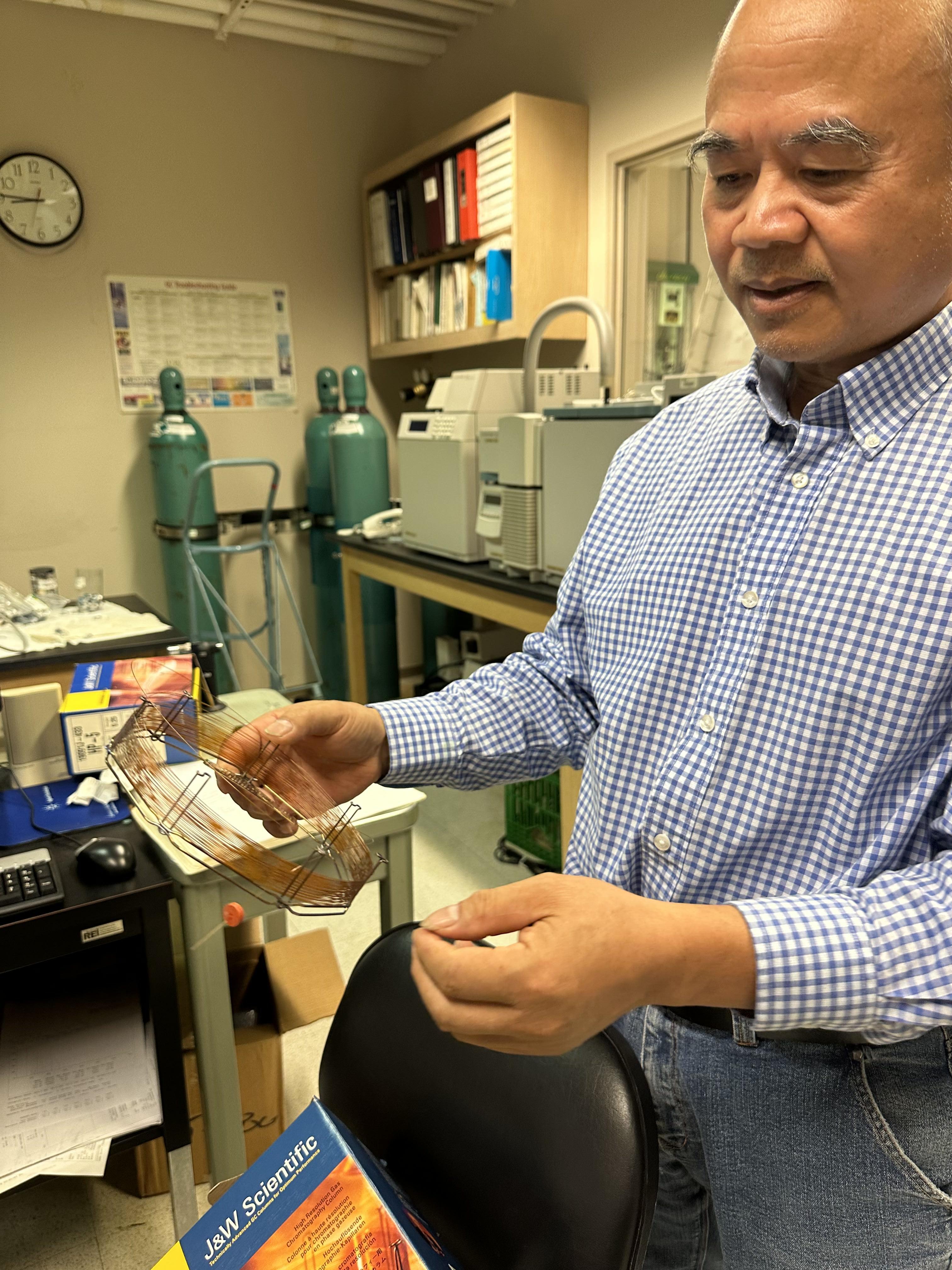

Rallming Yang, Senior Research Scientist and head of the Chemical Analysis Lab explains how FTIR Spectrometer works, at the RBI Chemical Analysis Lab

Providing research testing services to both internal and external stakeholders is an integral function of the Renewable Bioproducts Institute (RBI). These services include chemical analysis; corrosion; paper, board and box testing; pulp analysis; and pulp recovery analysis. Established over 25 years ago, RBI’s testing services are well-known in the industry for their quality and customer service. RBI is one of the ten interdisciplinary research institutes at Georgia Tech that champions innovation in converting biomass into value-added products, developing advanced chemical and bio-based refining technologies, and advancing excellence in manufacturing processes.

The RBI research testing services is a team of professional scientists and engineers who work together to provide information and offer solutions required by a manufacturers and users of biomass products, as well as Georgia Tech faculty and students engaged in research on campus. The multidisciplinary capabilities of the team make them uniquely qualified to address customers' technical needs in the areas of process and product development, and quality control. Where appropriate, the team involves RBI faculty and other staff experts to arrive at the best possible solution for their customers and users.

In this article, we will focus on a day’s work with the chemical analysis team. Headed by Rallming Yang, senior research scientist at RBI, the team is equipped to follow the Technical Association of the Paper and Pulp industry (TAPPI) standard of testing, which only a small number of labs in the country can do, and has also developed some of its own internal protocols. Yang leads two specific characterization programs within RBI: (1) the pulping and bleaching analysis, paper recycling, and recovery lab, and (2) the chemical analysis lab.

The chemical analysis team is busy year-round with research projects and testing services. In addition, during the Spring semester, the team also provides support to a paper science laboratory course for undergraduate and graduate students. In the recent times, chemical analysis of black liquor from pulp mills has kept the team busy with more than 30 projects completed by the team over three months for various industry customers. Currently, black liquor analysis continues to account for over 50% of the workload of the lab.

Black Liquor (BL) is a byproduct of a wood pulping and is released when cellulose fibers are separated from wood chips. BL contains lignin, which is used as a biofuel within the mill, and several other chemicals that are recovered and reused. In most pulp mills, nearly 50-70% of BL is converted into a convenient source of fuel or energy. Due to the important role played by black liquor in a paper mill, it needs to be tested regularly to ensure consistency in composition. The RBI chemical analysis lab gets BL samples from a pulp mill, who contact the lab by email to get their testing request into the queue. The process involved in the testing is very intense and has multiple steps that need to be carefully administered.

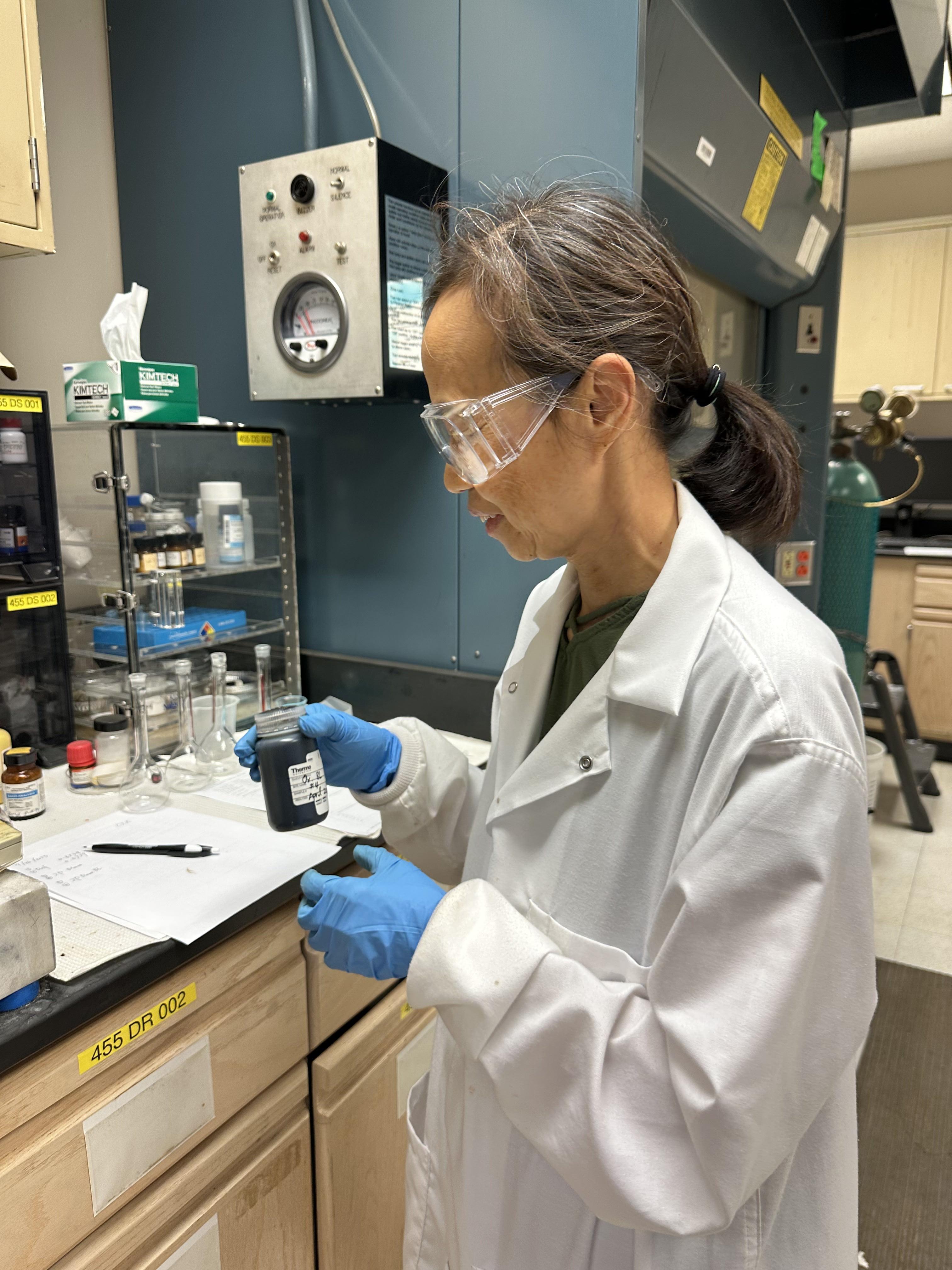

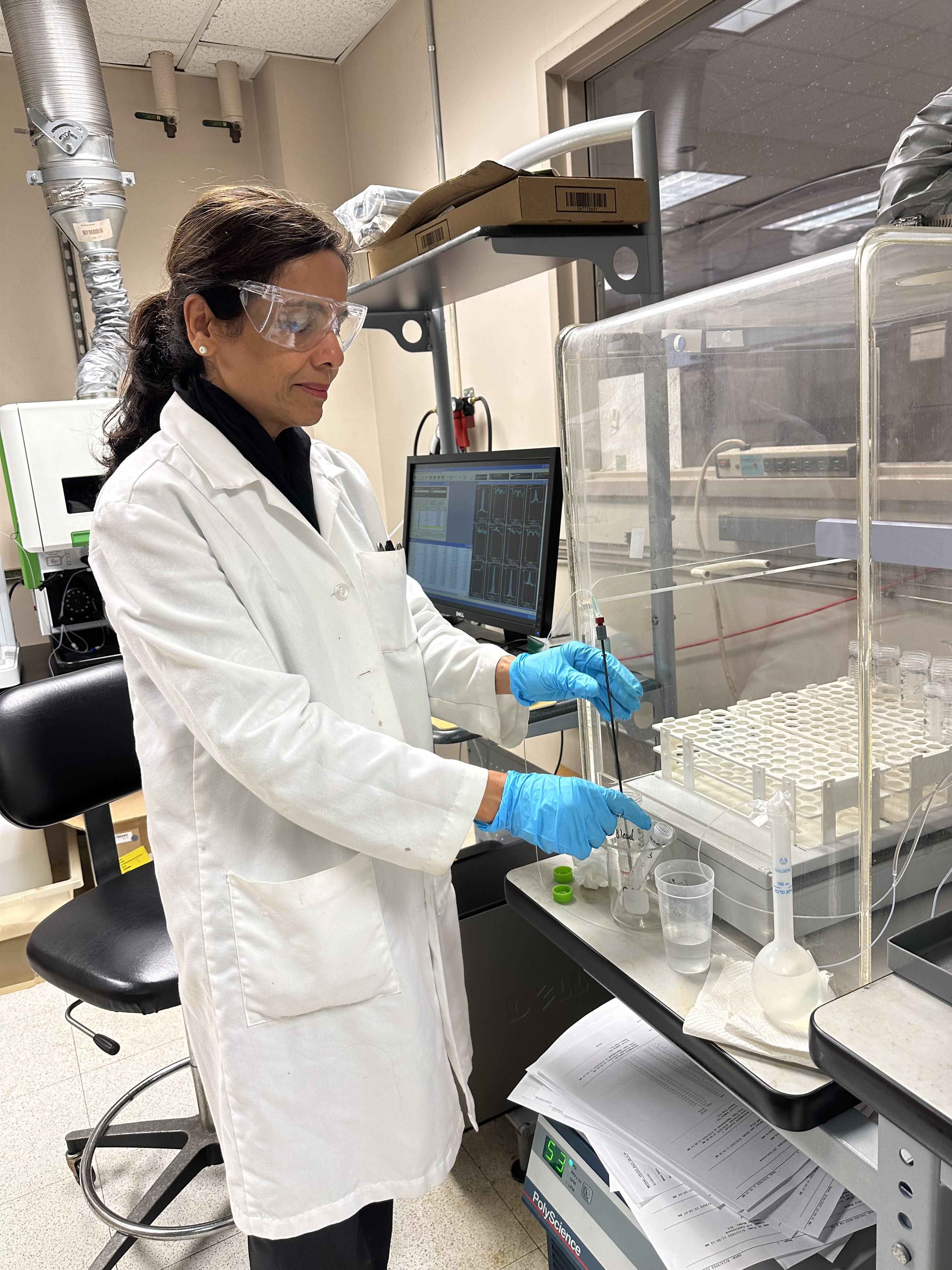

In the first step, inorganic elements in BL are identified by digesting it in a precise mixture of acids and filtering the mixture. The filtrate is introduced into an Inductively Coupled Plasma (ICP) Emission Spectrometer that can identify more than 70 different inorganic elements and compounds like sulfur, potassium, sodium, iron, calcium, etc. The next step involves identifying the proportion of anions like sulfate, chloride, thiosulfate. In this step, BL is diluted to a specific level and analyzed using a method called Capillary Ion Electrophoresis (CIE).

The next step involves analyzing BL for organic substances using two methods – gas chromatography mass spectrometry (GC/MS) and Fourier Transform Infrared Spectrometry (FTIR). For organic substances with a lower molecular weight of less than 600 Daltons (Da), GC/MS is employed where the gas chromatography separates the chemical mixture, and the mass spectrometry identifies each of the components.

The final step is to identify organic substances and polymers with higher molecular weights. For example, lignin is one of the main polymers in BL with a molecular weight higher than 600 Da. FTIR is used for testing during this step. Based on vibrations within each molecule, an FTIR spectrum allows identification of molecular groups within lignin. The equipment then uses a computer to identify the substances by comparing the sample spectrum with a built-in library. The RBI team provides detailed lab reports that is used by the pulp mill to adjust their operating parameters for trouble-free operations.

In addition to the chemical analysis of byproducts like black liquor and other chemical compounds, Rallming Yang’s team also conducts studies on pulping and bleaching, repulping, and fiber characterizations.

Xiaoyan Zeng, Research Scientist at RBI preparing black liquor for identifying anions

Diluted black liquor ready for testing

Tabassum Shah, Research Coordinator at RBI, tests black liquor using ICP Emission Spectrometer

Priya Devarajan || Research Communications Program Manager, RBI