Jun. 07, 2024

Nakia Melecio, the VentureLab Principal under the Office of Commercialization, has made remarkable progress in enhancing the grant programs of the National Institutes of Health (NIH). Over an intensive eight-month period, Melecio was part of an evaluation committee that focused on refining initiatives of the NIH’s National Cancer Institute, particularly the Small Business Transition Grant and other related grant programs.

“The experience was both enlightening and challenging,” Melecio said. “We engaged with faculty from over 20 universities to understand the diverse needs — from early-stage research to the commercialization of technology.” His pivotal role in streamlining the application processes for the Small Business Innovation Research and Small Business Technology Transfer programs has significantly enhanced their efficiency and accessibility.

A key aspect of Melecio’s efforts was to increase participation from historically underrepresented groups, with a significant focus on supporting historically Black colleges and universities and minority-serving institutions. His strategic insights have helped reshape these programs to better facilitate the commercialization of technologies developed within academic institutions.

Keith McGreggor, director of VentureLab, praised Melecio’s contributions. “Nakia’s work embodies our mission to transform research into viable market opportunities, ensuring broad access and benefit. The approval of the committee’s recommendations by the NCI leadership marks a significant advancement in our ongoing effort to make NIH funding more accessible and effective,” he said.

As these enhancements are implemented, they promise to significantly improve the landscape for commercializing technologies originating from university research, fostering broader innovation and practical application of groundbreaking discoveries.

The Office of Commercialization at Georgia Tech continues to support faculty and researchers as they navigate these improved opportunities, ensuring that the leadership and expertise within our community are directed toward national and global advancements in science and technology.

Stay engaged with the Office of Commercialization for ongoing updates on this and other initiatives.

News Contact

Lacey Cameron

Jun. 06, 2024

Ask a person to find a frying pan, and they will most likely go to the kitchen. Ask a robot to do the same, and you may get numerous responses, depending on how the robot is trained.

Since humans often associate objects in a home with the room they are in, Naoki Yokoyama thinks robots that navigate human environments to perform assistive tasks should mimic that reasoning.

Roboticists have employed natural language models to help robots mimic human reasoning over the past few years. However, Yokoyama, a Ph.D. student in robotics, said these models create a “bottleneck” that prevents agents from picking up on visual cues such as room type, size, décor, and lighting.

Yokoyama presented a new framework for semantic reasoning at the Institute of Electrical and Electronic Engineers (IEEE) International Conference on Robotics and Automation (ICRA) last month in Yokohama, Japan. ICRA is the world’s largest robotics conference.

Yokoyama earned a best paper award in the Cognitive Robotics category with his Vision-Language Frontier Maps (VLFM) proposal.

Assistant Professor Sehoon Ha and Associate Professor Dhruv Batra from the School of Interactive Computing advised Yokoyama on the paper. Yokoyama authored the paper while interning at the Boston Dynamics’ AI Institute.

“I think the cognitive robotic category represents a significant portion of submissions to ICRA nowadays,” said Yokoyama, whose family is from Japan. “I’m grateful that our work is being recognized among the best in this field.”

Instead of natural language models, Yokoyama used a renowned vision-language model called BLIP-2 and tested it on a Boston Dynamics “Spot” robot in home and office environments.

“We rely on models that have been trained on vast amounts of data collected from the web,” Yokoyama said. “That allows us to use models with common sense reasoning and world knowledge. It’s not limited to a typical robot learning environment.”

What is Blip-2?

BLIP-2 matches images to text by assigning a score that evaluates how well the user input text describes the content of an image. The model removes the need for the robot to use object detectors and language models.

Instead, the robot uses BLIP-2 to extract semantic values from RGB images with a text prompt that includes the target object.

BLIP-2 then teaches the robot to recognize the room type, distinguishing the living room from the bathroom and the kitchen. The robot learns to associate certain objects with specific rooms where it will likely find them.

From here, the robot creates a value map to determine the most likely locations for a target object, Yokoyama said.

Yokoyama said this is a step forward for intelligent home assistive robots, enabling users to find objects — like missing keys — in their homes without knowing an item’s location.

“If you’re looking for a pair of scissors, the robot can automatically figure out it should head to the kitchen or the office,” he said. “Even if the scissors are in an unusual place, it uses semantic reasoning to work through each room from most probable location to least likely.”

He added that the benefit of using a VLM instead of an object detector is that the robot will include visual cues in its reasoning.

“You can look at a room in an apartment, and there are so many things an object detector wouldn’t tell you about that room that would be informative,” he said. “You don’t want to limit yourself to a textual description or a list of object classes because you’re missing many semantic visual cues.”

While other VLMs exist, Yokoyama chose BLIP-2 because the model:

- Accepts any text length and isn’t limited to a small set of objects or categories.

- Allows the robot to be pre-trained on vast amounts of data collected from the internet.

- Has proven results that enable accurate image-to-text matching.

Home, Office, and Beyond

Yokoyama also tested the Spot robot to navigate a more challenging office environment. Office spaces tend to be more homogenous and harder to distinguish from one another than rooms in a home.

“We showed a few cases in which the robot will still work,” Yokoyama said. “We tell it to find a microwave, and it searches for the kitchen. We tell it to find a potted plant, and it moves toward an area with windows because, based on what it knows from BLIP-2, that’s the most likely place to find the plant.”

Yokoyama said as VLM models continue to improve, so will robot navigation. The increase in the number of VLM models has caused robot navigation to steer away from traditional physical simulations.

“It shows how important it is to keep an eye on the work being done in computer vision and natural language processing for getting robots to perform tasks more efficiently,” he said. “The current research direction in robot learning is moving toward more intelligent and higher-level reasoning. These foundation models are going to play a key role in that.”

Top photo by Kevin Beasley/College of Computing.

News Contact

Nathan Deen

Communications Officer

School of Interactive Computing

Jun. 03, 2024

Knitting, the age-old craft of looping and stitching natural fibers into fabrics, has received renewed attention for its potential applications in advanced manufacturing. Far beyond their use for garments, knitted textiles are ideal for designing and fabricating emerging technologies like wearable electronics or soft robotics — structures that need to move and bend.

Knitting transforms one-dimensional yarn into two-dimensional fabrics that are flexible, durable, and highly customizable in shape and elasticity. But to create smart textile design techniques that engineers can use, understanding the mechanics behind knitted materials is crucial.

Physicists from the Georgia Institute of Technology have taken the technical know-how of knitting and added mathematical backing to it. In a study led by Elisabetta Matsumoto, associate professor in the School of Physics, and Krishma Singal, a graduate researcher in Matsumoto’s lab, the team used experiments and simulations to quantify and predict how knit fabric response can be programmed. By establishing a mathematical theory of knitted materials, the researchers hope that knitting — and textiles in general — can be incorporated into more engineering applications.

Their research paper, “Programming Mechanics in Knitted Materials, Stitch by Stitch,” was published in the journal Nature Communications.

“For centuries, hand knitters have used different types of stitches and stitch combinations to specify the geometry and ‘stretchiness’ of garments, and much of the technical knowledge surrounding knitting has been handed down by word of mouth,” said Matsumoto.

But while knitting has often been dismissed as unskilled, poorly paid “women’s work,” the properties of knits can be more complex than traditional engineering materials like rubbers or metals.

For this project, the team wanted to decode the underlying principles that direct the elastic behavior of knitted fabrics. These principles are governed by the nuanced interplay of stitch patterns, geometry, and yarn topology — the undercrossings or overcrossings in a knot or stitch. "A lot of yarn isn’t very stretchy, yet once knit into a fabric, the fabric exhibits emergent elastic behavior," Singal said.

“Experienced knitters can identify which fabrics are stretchier than others and have an intuition for its best application,” she added. “But by understanding how these fabrics can be programmed and how they behave, we can expand knitting’s application into a variety of fields beyond clothing.”

Through a combination of experiments and simulations, Matsumoto and Singal explored the relationships among yarn manipulation, stitch patterns, and fabric elasticity, and how these factors work together to affect bulk fabric behavior. They began with physical yarn and fabric stretching experiments to identify main parameters, such as how bendable or fluffy the yarn is, and the length and radius of yarn in a given stitch.

They then used the experiment results to design simulations to examine the yarn inside a stitch, similar to an X-ray. It is difficult to see inside stitches during the physical measurements, so the simulations are used to see what parts of the yarn have interacted with other parts. The simulations are used to recreate the physical measurements as accurately as possible.

Through these experiments and simulations, Singal and Matsumoto showed the profound impact that design variations can have on fabric response and uncovered the remarkable programmability of knitting. "We discovered that by using simple adjustments in how you design a fabric pattern, you can change how stretchy or stiff the bulk fabric is," Singal said. "How the yarn is manipulated, what stitches are formed, and how the stitches are patterned completely alter the response of the final fabric."

Matsumoto envisions that the insights gleaned from their research will enable knitted textile design to become more commonly used in manufacturing and product design. Their discovery that simple stitch patterning can alter a fabric’s elasticity points to knitting’s potential for cutting-edge interactive technologies like soft robotics, wearables, and haptics.

“We think of knitting as an additive manufacturing technique — like 3D printing, and you can change the material properties just by picking the right stitch pattern,” Singal said.

Matsumoto and Singal plan to push the boundaries of knitted fabric science even further, as there are still numerous questions about knitted fabrics to be answered.

"Textiles are ubiquitous and we use them everywhere in our lives," Matsumoto said. "Right now, the hard part is that designing them for specific properties relies on having a lot of experience and technical intuition. We hope our research helps make textiles a versatile tool for engineers and scientists too."

Note: Sarah Gonzalez (Georgia Tech) and Michael Dimitriyev (Texas A&M) are also co-first authors of the study.

Citation: Singal, K., Dimitriyev, M.S., Gonzalez, S.E. et al. Programming mechanics in knitted materials, stitch by stitch. Nat Commun 15, 2622 (2024).

DOI: https://doi.org/10.1038/s41467-024-46498-z

Funding: Research Corporation for Science Advancement, National Science Foundation, and the Alfred P. Sloan Foundation

News Contact

Catherine Barzler, Senior Research Writer/Editor

Institute Communications

May. 31, 2024

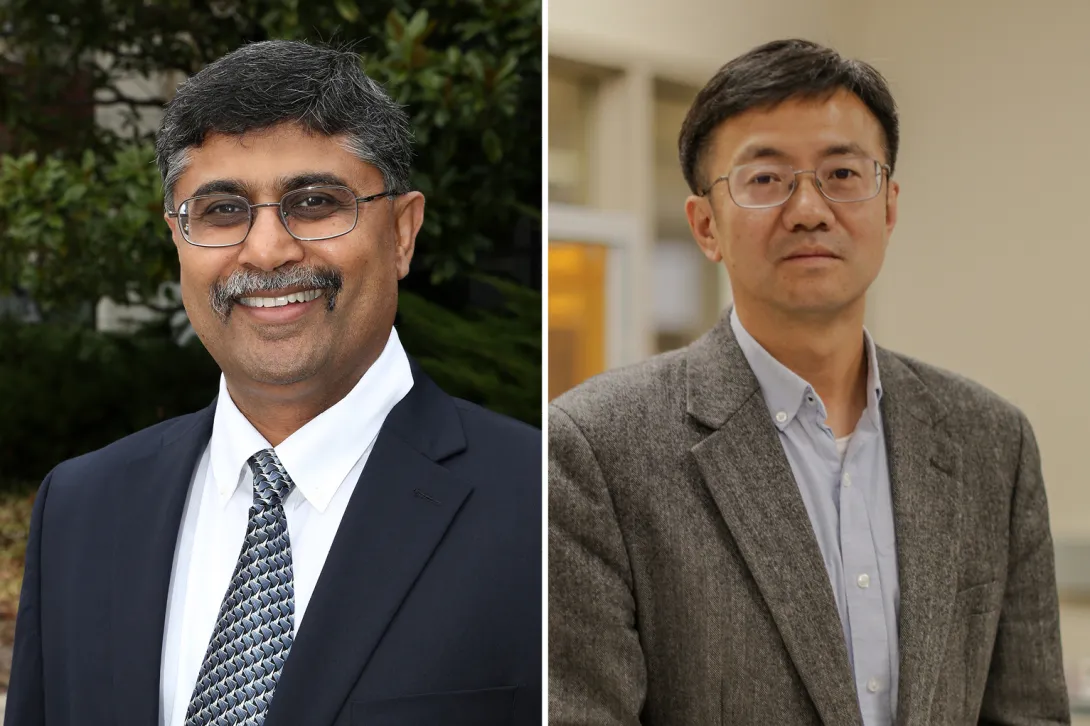

Two faculty members in the George W. Woodruff School of Mechanical Engineering will receive achievement awards from the American Society of Mechanical Engineers (ASME). Shreyes Melkote, who holds the Morris M. Bryan, Jr. Professorship in Mechanical Engineering, will receive the 2024 Milton C. Shaw Manufacturing Research Medal, and Professor Jerry Qi will receive the 2024 Warner T. Koiter Medal.

The Milton C. Shaw Manufacturing Research Medal, established in 2009, recognizes significant fundamental contributions to the science and technology of manufacturing processes.

"I am honored to receive this prestigious award. Milton C. Shaw was a giant in the manufacturing field, and to be recognized by an award named after him is very humbling," said Melkote, who also serves as the associate director for the Georgia Tech Manufacturing Institute.

The Warner T. Koiter Medal was established in 1996 and recognizes distinguished contributions to the field of solid mechanics with special emphasis on the effective blending of theoretical and applied elements of the discipline, as well as leadership in the international solid mechanics community.

Qi expressed his appreciation for his team upon learning of the award. “This award is really for my current and former students and postdoctoral scholars. It recognizes their work and innovations in a very special way," he said.

Qi's research is focused on the mechanics and 3D printing of soft active materials to enable 4D printing methods and the recycling of thermosetting polymers. He has developed several material models to describe the multiphysics and chemomechanical behaviors of soft active materials. He also pioneered several multimaterial 3D printing approaches that allow the integration of different polymers and functional materials into one system.

Melkote's primary area of research is manufacturing, and his secondary area of research is tribology, specifically in the science of precision material removal processes, new manufacturing process development including novel surface modification methods, the application of artificial intelligence and machine learning to solve complex problems in manufacturing, and advanced industrial robotics for precision manufacturing.

Melkote also credited the efforts and support of his students and colleagues. "This recognition would not have been possible without the high level of creativity and outstanding efforts of my graduate students and postdoctoral scholars, the support of my colleagues and mentors at Georgia Tech and beyond, and the opportunities and resources provided to me by the Woodruff School. I am truly grateful to all of them."

Both will be presented with their awards at upcoming ASME events. Melkote will receive his award at the ASME Manufacturing Science and Engineering Conference, June 17-21, in Knoxville, TN, and Qi will receive his at the ASME International Mechanical Engineering Congress and Exposition, November 17-21, in Portland, OR.

News Contact

Chloe Arrington

Communications Officer II

George W. Woodruff School of Mechanical Engineering

May. 30, 2024

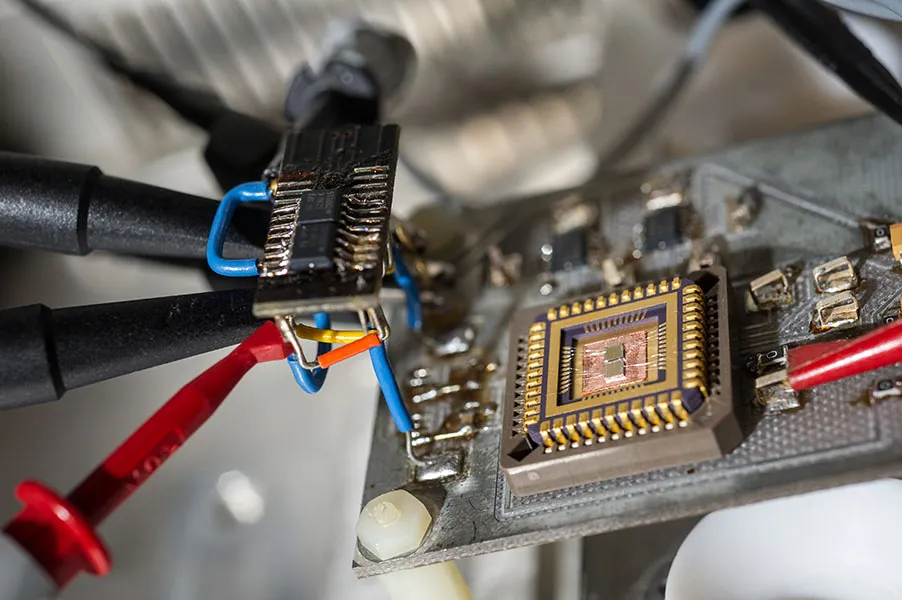

Semiconductors make our world run, but the industry faces a turning point. For decades, computer chip efficiency has doubled every two years, but that progress is slowing. To complicate the problem further, global demand for semiconductors threatens to outpace the supply. The U.S. has the opportunity to meet the growing need for chips — both by increasing domestic manufacturing and building up the workforce, which is at its lowest in decades. To bolster semiconductor research and manufacturing, in 2022, Congress passed the $52.7 billion bipartisan CHIPS and Science Act that President Joe Biden signed into law. New paradigms and pioneers are needed to make these critical advances.

Georgia Tech is playing a significant role in creating the next generation of chips, as the Institute is especially well positioned to innovate in the semiconductor field. All areas of the semiconductor stack — the components that build a chip, from hardware to artificial intelligence — are studied at Tech, and collaboration among faculty is a hallmark of its research enterprise. Such cooperation is necessary to build better chips, since they need to be reinvented in every layer of the stack.

News Contact

Media Contact: Tess Malone | tess.malone@gatech.edu

May. 29, 2024

Georgia Tech has been selected as one of six universities globally to receive funding for the newly established Global Industrial Technology Cooperation Center. The announcement was made by the Ministry of Trade, Industry, and Energy in South Korea during the Global Open Innovation Strategy Meeting in April.

The KIAT-Georgia Tech Semiconductor Electronics Center will receive $1.8 million to establish a sustainable semiconductor electronics research partnership between Korean companies, researchers, and Georgia Tech.

“I am thrilled to announce that we have secured funding to launch a groundbreaking collaboration between Georgia Tech’s world-class researchers and Korean companies,” said Hong Yeo, associate professor and Woodruff Faculty Fellow in the George W. Woodruff School of Mechanical Engineering and the Wallace H. Coulter Department of Biomedical Engineering. “This initiative will drive the development of cutting-edge technologies to advance semiconductor, sensors, and electronics research.”

Yeo will lead the center, and Michael Filler, interim executive director for the Institute of Electronics and Nanotechnology, and Muhannad Bakir, director of the 3D Advanced Packaging Research Center, will serve as co-PIs.

The center will focus on advancing semiconductor research, a critical area of technology that forms the backbone of modern electronics.

The Cooperation Center is a global technology collaboration platform designed to facilitate international joint research and development planning, partner matching, and local support for domestic researchers. The selection of Georgia Tech underscores the Institute’s leadership and expertise in the field of semiconductors.

News Contact

Amelia Neumeister

Research Communications Program Manager

May. 23, 2024

Yongsheng Chen, Bonnie W. and Charles W. Moorman IV Professor in Georgia Tech's School of Civil and Environmental Engineering, has been awarded a $300,000 National Science Foundation (NSF) grant to spearhead efforts to enhance sustainable agriculture practices using innovative AI solutions.

The collaborative project, named EAGER: AI4OPT-AG: Advancing Quad Collaboration via Digital Agriculture and Optimization, is a joint effort initiated by Georgia Tech in partnership with esteemed institutions in Japan, Australia, and India. The project aims to drive advancements in digital agriculture and optimization, ultimately supporting food security for future generations.

Chen, who also leads the Urban Sustainability and Resilience Thrust for the NSF Artificial Intelligence Research Institute for Advances in Optimization (AI4OPT), is excited about this new opportunity. "I am thrilled to lead this initiative, which marks a significant step forward in harnessing artificial intelligence (AI) to address pressing issues in sustainable agriculture," he said.

Highlighting the importance of AI in revolutionizing agriculture, Chen explained, "AI enables swift, accurate, and non-destructive assessments of plant productivity, optimizes nutritional content, and enhances fertilizer usage efficiency. These advancements are crucial for mitigating agriculture-related greenhouse gas emissions and solving climate change challenges."

To read the full agreement, click here.

News Contact

Breon Martin

AI Research Communications Manager

Georgia Tech

May. 23, 2024

Our SCL Industry Advisory Board has asked our team to invest in providing a future perspective on the evolution of Supply Chains and where we think the turns, peaks, and valleys will lie. We will begin an effort to offer a credible future perspective, but it will take some time. In the meantime, we will share some perspective and thoughts on pieces we see that are worth a good read. We will also offer some advice for those who need guidance or an additional data point on their action plans to lead their Supply Chain. The referenced article is a good one. Please scan our summary and if it piques your interest, the article is a good 15-minute read. Here are our thoughts:

In today's rapidly evolving global landscape, supply chain leaders must adopt a forward-thinking approach to ensure resilience, innovation, and sustainability. As disruption becomes a constant, assessing supply chains from a risk and resiliency perspective is no longer optional—it is essential. This article explores key themes for future-proofing supply chains, offering a self-assessment framework and insights into what leaders are doing to stay ahead.

Disruption is now a permanent fixture in supply chains, driven by factors such as geopolitical tensions, climate change, and technological advancements. To navigate this new reality, companies must develop a risk and resiliency capability that informs long-term infrastructure, supplier, and sourcing strategies, as well as supply chain planning. This proactive approach is critical to maintaining operational continuity and competitive advantage in an increasingly unpredictable world.

Implementing changes such as nearshoring or reshoring is a complex and costly endeavor that requires a long-term commitment. While these strategies can mitigate risks and enhance supply chain resilience, they involve significant investment and time. Leaders must be pragmatic about the costs and benefits, ensuring that investments align with long-term strategic goals and risk reduction priorities.

Artificial intelligence (AI) and digital technologies hold immense promise for enhancing supply chain efficiency and agility. However, managing expectations and maintaining discipline around the problems to be solved is crucial. Organizations must realistically assess their current readiness and capability to adopt these technologies, balancing short-term realities with long-term potential benefits. Successful digital transformation requires a clear strategy, substantial investment, and a culture willing to embrace change.

Demographic shifts and skill gaps necessitate a strategic approach to talent management in supply chains. Organizations must be intentional about understanding their current workforce realities and planning for the future. This involves investing in continuous upskilling and reskilling programs to ensure that employees are equipped with the skills needed to navigate the complexities of modern supply chains. Building a diverse and inclusive talent pipeline is also critical for fostering innovation and resilience.

Sustainability must be embedded in supply chain strategies to create long-term value for businesses and society. While the journey toward sustainability can be challenging and requires a balanced approach, it is essential for future competitiveness. Organizations must objectively assess what is beneficial for both the business and the environment, balancing short-term operational needs with the long-term interests of future generations. This involves setting clear sustainability targets, investing in sustainable technologies, and engaging stakeholders across the supply chain.

In a competitive marketplace, focusing on a clear and evolving value proposition for customers is crucial. Companies cannot simply cut costs to achieve success; they must continually redefine their value proposition to differentiate themselves from competitors and meet changing consumer demands. This requires a deep understanding of customer needs, continuous innovation, and the ability to swiftly adapt to market changes.

To evaluate your organization's readiness for the future of supply chain management, consider the following questions: How robust is your risk management strategy? Are you proactive in identifying potential disruptions and developing contingency plans? Do you have a clear long-term plan for initiatives like nearshoring, and are you realistic about the costs and benefits? What is your current level of digital maturity, and are you clear about the specific problems AI can solve for you? Are you investing sufficiently in upskilling and reskilling your workforce, and how are you addressing demographic shifts and skill gaps? Do you have measurable sustainability goals, and how do you balance short-term business needs with long-term environmental goals? Finally, how well do you understand your customers' evolving needs, and are you innovating to maintain a competitive edge?

Leading organizations are already taking significant steps to address these challenges. In the realm of risk and resiliency, they are developing comprehensive risk management frameworks and investing in technologies that enhance supply chain visibility and agility. For change management, they are committing to long-term strategic initiatives like nearshoring while being pragmatic about the associated costs and timelines. In the area of AI and digital readiness, companies are implementing AI-driven solutions for demand forecasting and inventory management while continuously refining their digital strategies. Regarding talent strategy, they are creating robust upskilling programs and fostering a culture of continuous learning and adaptability. In sustainability, they are setting ambitious targets and collaborating with suppliers to achieve them. And in terms of customer value, they are leveraging data analytics to gain deeper insights into customer preferences and tailoring their offerings accordingly.

We welcome your reaction and thoughts on this article and if you would like to talk about it, let us know and we’ll set up some time.

Thanks,

Chris and the SCL team

News Contact

info@scl.gatech.edu

May. 23, 2024

The Biden-Harris Administration announced that the U.S. Department of Commerce and Absolics, an affiliate of the Korea-based SKC, have signed a non-binding preliminary memorandum of terms to provide up to $75 million in direct funding under the CHIPS and Science Act to help advance U.S. technology leadership. The proposed investment would support the construction of a 120,000 square-foot facility in Covington, Georgia and the development of substrates technology for use in semiconductor advanced packaging. Started through a collaboration with the 3D Packaging Research Center at Georgia Tech, Absolics’ project serves as an example of American lab-to-fab development and production.

"Glass-core packaging holds the promise to revolutionize the field of advanced packaging and impact major paradigms such as artificial intelligence, mm-wave/THz communication, and photonic connectivity," said Muhannad Bakir, Dan Fielder Professor in the School of Electrical and Computer Engineering and Director of the 3D Systems Packaging Research Center at Georgia Tech. "We look forward to supporting Absolics in establishing a glass-core packaging facility in the State of Georgia through workforce development initiatives."

Because of President Biden’s CHIPS and Science Act, this proposed investment would support over an estimated 1,000 construction jobs and approximately 200 manufacturing and R&D jobs in Covington and enhance innovation capacity at Georgia Institute of Technology, supporting the local semiconductor talent pipeline.

The proposed investment with Absolics is the first proposed CHIPS investment in a commercial facility supporting the semiconductor supply chain by manufacturing a new advanced material.

News Contact

Amelia Neumeister

Research Communications Program Manager

May. 22, 2024

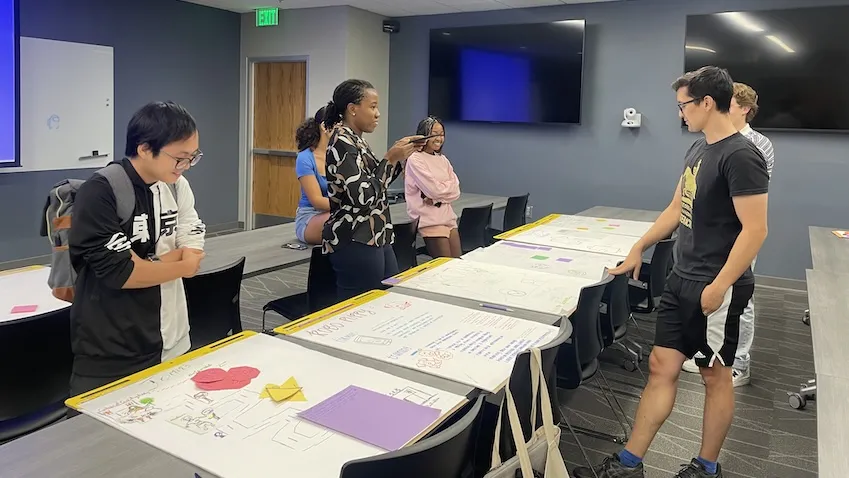

Working on a multi-institutional team of investigators, Georgia Tech researchers have helped the state of Georgia become the epicenter for developing K-12 AI educational curriculum nationwide.

The new curriculum introduced by Artificial Intelligence for Georgia (AI4GA) has taught middle school students to use and understand AI. It’s also equipped middle school teachers to teach the foundations of AI.

AI4GA is a branch of a larger initiative, the Artificial Intelligence for K-12 (AI4K12). Funded by the National Science Foundation and led by researchers from Carnegie Mellon University and the University of Florida, AI4K12 is developing national K-12 guidelines for AI education.

Bryan Cox, the Kapor research fellow in Georgia Tech’s Constellation Center for Equity in Computing, drove a transformative computer science education initiative when he worked at the Georgia Department of Education. Though he is no longer with the DOE, he persuaded the principal investigators of AI4K12 to use Georgia as their testing ground. He became a lead principal investigator for AI4GA.

“We’re using AI4GA as a springboard to contextualize the need for AI literacy in populations that have the potential to be negatively impacted by AI agents,” Cox said.

Judith Uchidiuno, an assistant professor in Georgia Tech’s School of Interactive Computing, began working on the AI4K12 project as a post-doctoral researcher at Carnegie Mellon under lead PI Dave Touretzky. Joining the faculty at Georgia Tech enabled her to be an in-the-classroom researcher for AI4GA. She started her Play and Learn Lab at Georgia Tech and hired two research assistants devoted to AI4GA.

Focusing on students from underprivileged backgrounds in urban, suburban, and rural communities, Uchidiuno said her team has worked with over a dozen Atlanta-based schools to develop an AI curriculum. The results have been promising.

“Over the past three years, over 1,500 students have learned AI due to the work we’re doing with teachers,” Uchidiuno said. “We are empowering teachers through AI. They now know they have the expertise to teach this curriculum.”

AI4GA is in its final semester of NSF funding, and the researchers have made their curriculum and teacher training publicly available. The principal investigators from Carnegie Mellon and the University of Florida will use the curriculum as a baseline for AI4K12.

STARTING STUDENTS YOUNG

Though AI is a complex subject, the researchers argue middle schoolers aren’t too young to learn about how it works and the social implications that come with it.

“Kids are interacting with it whether people like it or not,” Uchidiuno said. “Many of them already have smart devices. Some children have parents with smart cars. More and more students are using ChatGPT.

“They don’t have much understanding of the impact or the implications of using AI, especially data and privacy. If we want to prepare students who will one day build these technologies, we need to start them young and at least give them some critical thinking skills.”

Will Gelder, a master’s student in Uchidiuno’s lab, helped analyze data exploring the benefits of co-designing the teaching curriculum with teachers based on months of working with students and learning how they understand AI. Rebecca Yu, a research scientist in Uchidiuno’s lab, collected data to determine which parts of the curriculum were effective or ineffective.

Through the BridgeUP STEM Program at Georgia Tech, Uchidiuno worked with high school students to design video games that demonstrate their knowledge of AI based on the AI4GA curriculum. Students designed the games using various maker materials in 2D and 3D representations, and the games are currently in various stages of development by student developers at the Play and Learn Lab.

“The students love creative projects that let them express their creative thoughts,” Gelder said. “Students love the opportunity to break out markers or crayons and design their dream robot and whatever functions they can think of.”

Yu said her research shows that many students demonstrate the ability to understand advanced concepts of AI through these creative projects.

“To teach the concept of algorithms, we have students use crayons to draw different colors to mimic all the possibilities a computer is considering in its decision-making,” Yu said.

“Many other curricula like ours don’t go in-depth about the technical concepts, but AI4GA does. We show that with appropriate levels of scaffolding and instructions, they can learn them even without mathematical or programming backgrounds.”

EMPOWERING TEACHERS

Cox cast a wide net to recruit middle school teachers with diverse student groups. A former student of his answered the call.

Amber Jones, a Georgia Tech alumna, taught at a school primarily consisting of Black and Latinx students. She taught a computer science course that covered building websites, using Excel, and basic coding.

Jones said many students didn’t understand the value and applications of what her course was teaching until she transitioned to the AI4GA curriculum.

“AI for Georgia curriculum felt like every other lesson tied right back to the general academics,” Jones said. “I could say, ‘Remember how you said you weren’t going to ever use y equals mx plus b? Well, every time you use Siri, she's running y equals mx plus b.’ I saw them drawing the connections and not only drawing them but looking for them.”

Connecting AI back to their other classes, favorite social media platforms, and digital devices helped students understand the concepts and fostered interest in the curriculum.

Jones’s participation in the program also propelled her career forward. She now works as a consultant teaching AI to middle school students.

“I’m kind of niche in my experiences,” Jones said. “So, when someone says, ‘Hey, we also want to do something with a young population that involves computer science,’ I’m in a small pool of people that can be looked to for guidance.”

AI4GA quickly cultivated a new group of experts within a short timeframe.

“They’ve made their classes their own,” Cox said. “They add their own tweaks. Over the course of the project, the teachers were engaged in cultivating the lessons for their experience and their context based on the identity of their students.”

News Contact

Nathan Deen

Communications Officer

School of Interactive Computing