Apr. 04, 2023

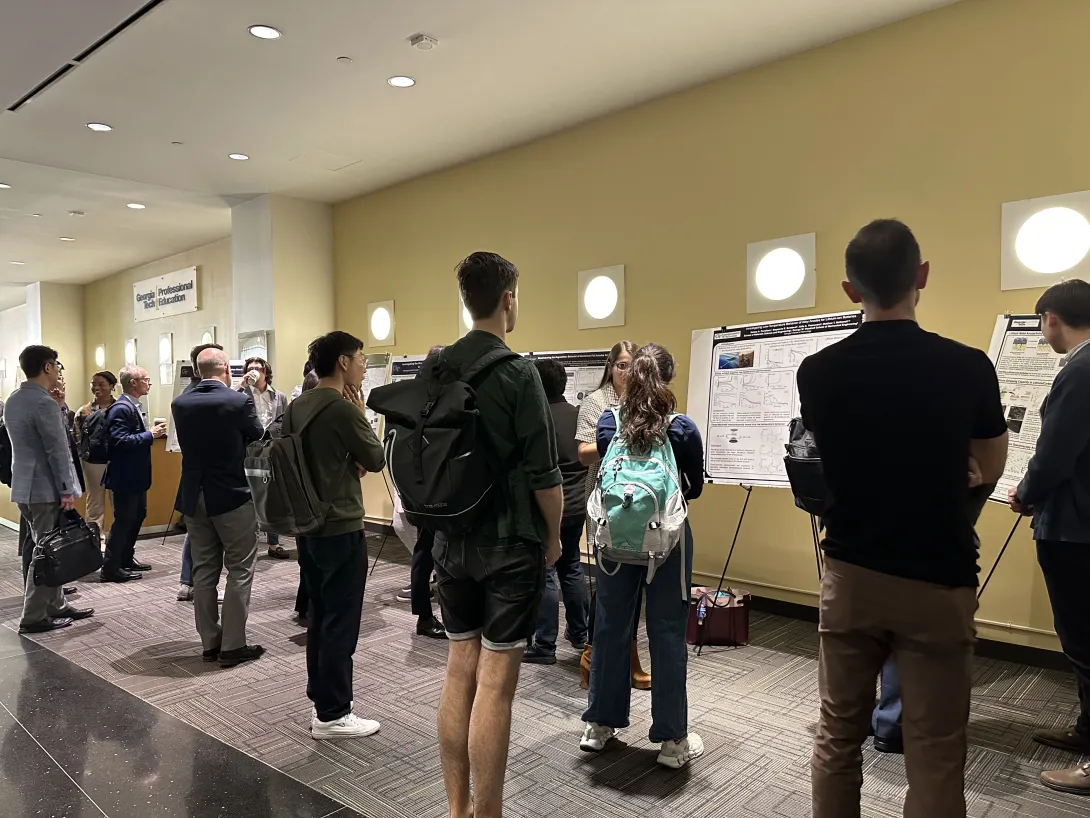

Georgia Tech Battery Day opened with a full house on March 30, 2023, at the Global Learning Center in the heart of Midtown Atlanta. More than 230 energy researchers and industry participants convened to discuss and advance energy storage technologies via lightning talks, panel discussions, student poster sessions, and networking sessions throughout the day. Matt McDowell, associate professor in the Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering as well as the initiative lead for energy storage at the Strategic Energy Institute and the Institute of Materials, started the day with an overview of the relevant research at Georgia Tech. His talk shed light on Georgia becoming the epicenter of the battery belt of the Southeast with recent key industry investments and the robust energy-storage research community present at Georgia Tech.

According to the Metro Atlanta Chamber of Commerce, since 2020, Georgia has had $21 billion invested or announced in EV-related projects with 26,700 jobs created. With investments in alternate energy technologies growing exponentially in the nation, McDowell revealed Georgia Tech is well-positioned to make an impact on the next generation energy storage technologies and extended an open invitation to industry members to partner with researchers. As one of the most research-intensive academic institutions in the nation, Georgia Tech has more than $1.3 billion in research and other sponsored funds and produces the highest number of engineering doctoral graduates in the nation.

“More than half of Georgia Tech's strategic initiatives are focused on improving the efficiency and sustainability of energy storage, supporting clean energy sources, and mitigating climate change," said Chaouki Abdallah, executive vice president for research at Georgia Tech. "As a leader in battery technologies research, we are bringing together engineers, scientists, and researchers in academia and industry to conduct innovative research to address humanity's most urgent and complex challenges, and to advance technology and improve the human condition."

Rich Simmons, director of research and studies at the Strategic Energy Institute moderated the first panel discussion that included industry panelists from Panasonic, Cox Automotive, Bluebird Corp., Delta Airlines and Hyundai Kia. The panelists analyzed the opportunities and challenges in the electric transportation sector and explained their current focus areas in energy storage. The panel affirmed that while EVs have been around for more than three decades, the industry is still in its infancy and there is a huge potential to advance technology in all areas of the EV sector.

The discussion also brought forth important factors like safety, lifecycle, and sustainability in driving innovations in the energy storage sector. The attendees also discussed supply chain issues, a hot topic in almost all sectors of the nation, and the need to develop a diversity of resources for more resilient systems. The industry panelists affirmed a strong interest in partnering on research and development projects as well as gaining access to university talent.

Gleb Yushin, professor in the School of Material Science and Engineering and co-founder of Sila Nanotechnologies Inc., presented his battery research and development success story at Georgia Tech. Sila is a Georgia Tech start-up founded in 2011 and has produced the world’s first commercially available high-silicon-content anode for lithium-ion batteries in 2021. Materials manufactured in its U.S. facilities will power electric vehicles starting with the Mercedes-Benz G-class series in 2023.

The program included lightning talks on cutting-edge research in battery materials, specifically solid-state electrolytes and plastic crystal embedded elastomer electrolytes (PCEEs) by Seung Woo Lee, associate professor in the George W. Woodruff School of Mechanical Engineering. Santiago Grijalva, professor in the School of Electrical and Computer Engineering, discussed the challenges and opportunities for the successful use of energy storage for the grid.

Tequila Harris, initiative lead for Energy and Manufacturing and professor in the George W. Woodruff School of Mechanical Engineering, spoke to energy materials and carbon-neutral applications. Presenting a case for roll-to-roll manufacturing of battery materials, Harris said that the need for quick, high yield manufacturing processes and alternative materials and structures were important considerations for the industry.

Materials, manufacturing, and market opportunities were the topic for the next panel moderated by McDowell and included panelists from Albemarle, Novelis, Solvay, Truist Securities, and Energy Impact Partners. Analyzing the current challenges, the panelists brought up hiring and workforce development, increasing capacity and building the ecosystem, decarbonizing existing processes, and understanding federal policies and regulations.

Lightning talks later in the afternoon by researchers at Georgia Tech touched on the latest developments in the cross-disciplinary research bridging mechanical engineering, chemical engineering, AI manufacturing, and material science in energy storage research. Topics included safe rechargeable batteries with water-based electrolytes (Nian Liu, assistant professor, School of Chemical & Biomolecular Engineering), AI-accelerated manufacturing (Aaron Stebner, associate professor, School of Materials Science and Engineering), battery recycling (Hailong Chen, associate professor, School of Materials Science and Engineering), and parametric life-cycle models for a solid-state battery circular economy (Ilan Stern, research scientist from GTRI).

Another industry panel on grid, infrastructure and communities moderated by Faisal Alamgir, professor in the School of Materials Science and Engineering included panelists from Southern Company, Stryten Energy, and the Metro Atlanta Chamber of Commerce. Improving the grid resiliency and storage capacity; proximity to the energy source; optimizing and implementing new technology in an equitable way; standardization of the evolving business models; economic development and resource building through skilled workforce; educating the consumer; and getting larger portions of the grid with renewable energy were top of mind with the panelists.

“Energy-storage-related R&D efforts at Georgia Tech are extensive and include next-gen battery chemistry development, battery characterization, recycling, and energy generation and distribution,” said McDowell. “There is a tremendous opportunity to leverage the broad expertise we bring to advance energy storage systems. Battery Day has been hugely successful in not only bringing this expertise to the forefront, but also in affirming the need for continued interaction with the companies engaged in this arena. Our mission is to serve as a centralized focal point for research interactions between companies in the battery/EV space and faculty members on campus.”

News Contact

Priya Devarajan || SEI Communications Manager

Apr. 03, 2023

Georgia Institute of Technology’s Center for Education Integrating Science, Mathematics, and Computing (CEISMC) is at the center of a new statewide initiative combining artificial intelligence and manufacturing innovations with transformational workforce development and K-12 outreach. The Georgia Artificial Intelligence Manufacturing Corridor project (Georgia AIM) is supported by a record-shattering $65 million grant Georgia Tech received in September 2022 from the U.S. Department of Commerce’s Economic Development Administration.

Georgia AIM will support a total of nine inter-related projects throughout the state and is designed to increase job and wage opportunities in distressed and rural communities and among historically underrepresented and underserved people. Georgia AIM targets rural residents, women, Black, Indigenous and People of Color (BIPOC), those living with disabilities, and veterans — groups historically underrepresented in manufacturing. Through innovation, collaboration, education, and participation, Georgia AIM will provide the tools and knowledge to empower these communities to participate fully in a diverse AI manufacturing workforce.

“Many people have preconceived notions about manufacturing and may not be able to see how they could possibly connect to it," said Roxanne Moore, Woodruff School of Mechanical Engineering’s senior research engineer and director of CEISMC’s K-12 InVenture Prize program. “What they may not realize is that manufacturing is what brings new ideas to life. AI is rapidly reshaping the manufacturing industry and changing the landscape for job opportunities. The work that we are doing will position Georgia to lead the nation into the future of AI and manufacturing.”

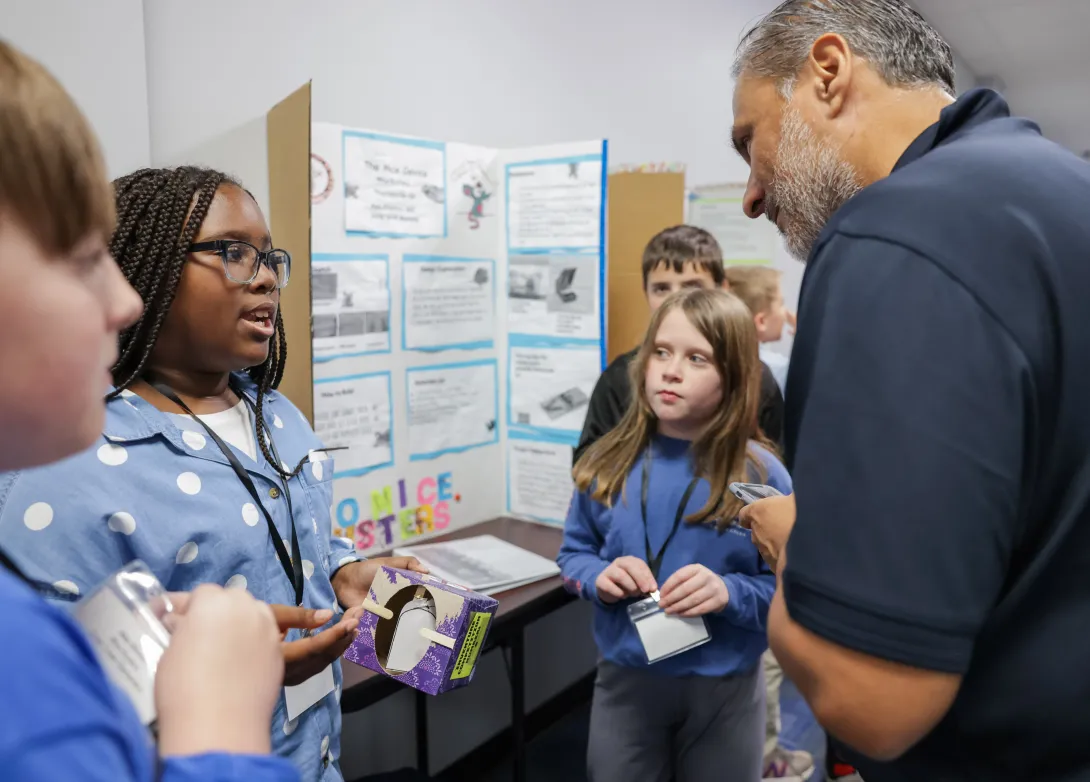

Moore explains that through Georgia AIM, CEISMC will expand its K-12 InVenture Prize invention and entrepreneurship program to collaborate with school districts and businesses in Southwest Georgia, Southeast Georgia and Northeast Georgia. The initiative will expand on existing partnerships Georgia Tech has established with technical colleges and minority-serving institutions.

The project will reach at least 1,000 K-12 students and 100 teachers from underserved areas, with a focus on rural communities via existing programs at Georgia Tech, other nonprofits, the Technical College System of Georgia, the Southwest Georgia Regional Commission, local manufacturers, and K-12 school leaders, Moore said.

“We need to illustrate the powerful relationships between innovation, entrepreneurship, and manufacturing so that students can see how ideas come to life and how they can improve their communities,” said Moore. “It is my hope that these regional ecosystems become a role model for how educational institutions can support each other in expanding access to high-quality STEM experiences for diverse students who typically are not empowered to create their futures.”

As part of Georgia AIM, CEISMC will also expand its offerings through partnerships with the institute’s GoSTEM program to better serve Latino populations. GoSTEM is a collaborative partnership at Georgia Tech between CEISMC and Institute Diversity, Equity and Inclusion (IDEI). Its mission is to promote STEM academic achievement and college attendance among Latino and other cultural and linguistic minority K-12 students. Plans include translating existing invention and entrepreneurship curriculum into Spanish, adding lessons to the curriculum on AI and manufacturing, assisting with the development of regionally focused curricula, and expanding training and events to make them more inclusive.

“Our goal is to make invention education accessible to everyone in the state, especially those who may have been previously left out of the conversation,” said Danyelle Larkin, educational outreach manager with CEISMC. “By going into more rural areas of the state and working to develop multi-lingual curricula that is focused on the needs of the region, we hope to serve as a national model for how to accelerate the transition to automation in manufacturing while diversifying the next generation of AI leadership.

Additional Georgia AIM expansion plans for CEISMC and K-12 InVenture Prize include supporting an existing high school entrepreneurship program in Fitzgerald and working with Albany State University to host teacher workshops, support local schools, and host regional competitions with a focus on inventiveness and the entrepreneurial mindset.

"The overall goal of Georgia AIM is to establish the United States as a leader in AI manufacturing while making sure that these systems complement rather than replace existing workers,” Larkin said. “The work that we are doing in CEISMC plays an integral role in Georgia AIM with our specific expertise in weaving invention education and entrepreneurship into K-12 classrooms and connecting with diverse communities. This huge grant gives us a chance to amplify our work and bring even more people into the AI conversation. It’s about building a better, more equitable future for the people of Georgia.”

—Randy Trammell, CEISMC Communications

Mar. 23, 2023

Women make up just 24% of the automotive industry, but Georgia Tech graduates Jenn Voelker and Julia Vorpahl haven't let statistics stop them from paving their own way in a male-dominated field.

Both Voelker and Vorpahl work for Karma Automotive, a luxury electric vehicle manufacturer based in California. Beginning with their time at Tech, they've never let gender bias stop them from pursuing their passion.

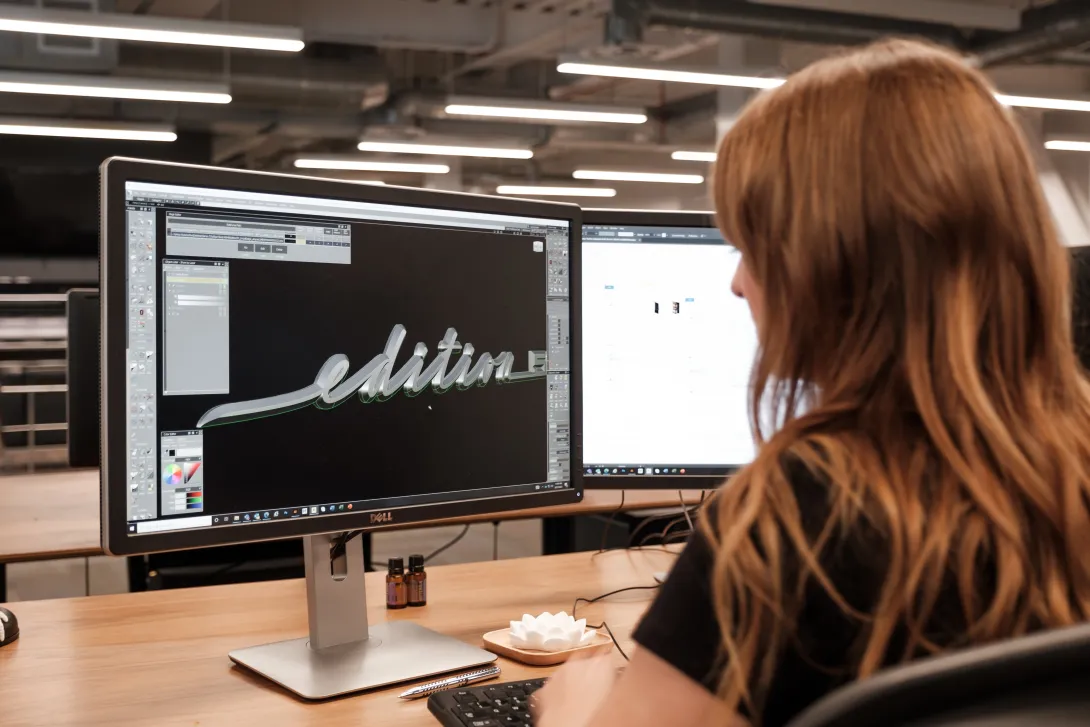

"It's math," Vorpahl, a visualization and digital design modeler at Karma, said. "You either get the question right, or you get the question wrong. I think that attitude really helps when you get into a professional environment. It teaches you to have tougher skin where if you are the best for that job, you will get the job. That's what Georgia Tech instilled."

Vorpahl grew up in the industry watching her family operate what is now the oldest independently owned Mercedes-Benz dealer in metro Atlanta after her grandfather, an engine designer for the German automaker, came to America and opened the shop in 1967. She arrived at Georgia Tech unsure if she'd follow in her family's footsteps, but ultimately, she landed an internship at Daimler, the nation's largest commercial vehicle manufacturer.

While other interns came in with a background in automotive design, Vorpahl’s willingness to learn and tireless work ethic landed her a full-time job as the only woman in the company's design studio.

During her three years at Daimler before accepting her position at Karma in 2022, she'd occasionally make the drive from Portland, Oregon, back to Georgia. Along the way, she crossed paths with truckers, who often expressed surprise that Vorpahl was among those behind the scenes designing their rigs. She often heard questions like “Why do you work there?” or “How did you end up there?”

And her response was simple. "Women like cars, too.”

That rang true through Voelker's childhood as well. When the senior director of program management for Karma arrived in Atlanta for her first year at Georgia Tech, she knew she'd found a place that could help her turn an aptitude for math and science, and a fervor for cars, into a career.

"Best move I ever made," Voelker said on her decision to enroll at Tech, although it wasn't just the Institute's stellar reputation that lured her from her home state of New Hampshire. "I visited campus in February. There was 6 feet of snow on the ground and then I came to Atlanta, and the flowers were blooming."

After changing her major from mechanical engineering to industrial design, Voelker got her foot in the door through an internship with Masterack, a commercial cargo vehicle equipment manufacturer based in Atlanta. She attended Tech at a time when women made up around 27% of the undergraduate population, so when she entered the workforce, she wasn't fazed. "It never bothered me. I have always felt like I fit right in, especially when it's the right school, the right class, or the right company where everybody appreciates learning from each other and working together towards a common goal," she said.

In fact, her experience on North Avenue taught her to always keep learning and never give up, a piece of advice she now passes along to other women entering the industry.

"Don’t be afraid to give your opinion in meetings, speak up and use all of the knowledge that you've learned over the years toward whatever project you're working on," said Voelker, who worked her way up the ladder at Masterack for 18 years before seeking a new challenge at Karma. “That's one thing that I haven't backed down on. If I have a strong opinion about something, I have no fear of saying it.”

Vorpahl and Voelker each commended Karma for their dedication to promoting hard-working women and a culture that fosters diversity — a principle that Vorpahl especially values after completing two study abroad programs at the University of Singapore and the University of Strathclyde.

“One of the biggest advantages was seeing how people from different countries approach design and how different schools approach design. You don’t want a bunch of people who all think exactly the same way. Otherwise, we’d all be driving around in the exact same vehicle,” she said.

Leading Karma’s commercial vehicle product line, Voelker noted that she has continued to see more women in leadership positions and at industry conferences, and she hopes that momentum carries over to the next generation. Highlighting the importance of igniting both young girls’ and boys' interest in STEM, Voelker recently spoke to a local second grade class to share her experiences.

"I've been really fortunate to have had some great mentors over my career, so I love to pay it forward to the younger generation," she said. "They were so excited, and I hope that stays with them and excites them to learn more about engineering."

In addition to providing an example to young women of how to succeed in a competitive industry, Vorpahl also hopes to share the technical aspects of what she's learned in the field with her alma mater and offer future graduates a roadmap to a career in automotive design.

"The students would thrive in this industry because it is so nitpicky, and Tech minds would just love it," she said. "There's not really a direct path from the Georgia Tech studios into car studios, so I'm hoping that I can show them that path."

Voelker and Vorpahl are bonded by their employer and their alma mater, but it’s their shared passion for seeing their hard work hit the pavement that continues to drive them.

Mar. 21, 2023

Idling at a crossroads no longer, the automotive industry is embracing electrification like never before. With more electric vehicles purchased in 2022 than any year prior, consumers are beginning to follow their lead. Yet, while opportunity abounds, new challenges will require an innovative approach to ensure a sustainable and accessible electric future for all.

With historic investments from major players in the EV space, including Rivian, Kia, and Hyundai, the state of Georgia is uniquely positioned to serve as a leader in this effort. As the state's leading research institute, Georgia Tech is on the cutting edge of the movement.

The transportation sector is the largest greenhouse gas emitter in the U.S. at nearly 30%, with passenger vehicles accounting for around 80% of the sector's total output1 as of 2019. Electric vehicles are widely regarded as a budding solution to reduce emissions, but even as both demand and production continue to increase, EVs currently account for around 1% of the cars on America's roadways.

From the supply chain to the infrastructure needed to support alternative-fuel vehicles alongside consumer hesitancy, achieving the goals set by both the public and private sectors — including the Biden Administration's target of EVs making up at least 50% of new car sales by 2030 — will not be easy. Through research and development, policy, and collaboration, Tech experts are working toward finding solutions that will serve as catalysts during this transitionary period for the environment and the way Americans drive.

News Contact

Steven Gagliano - Communications Officer

Institute Communications

Mar. 10, 2023

This news release first appeared in the University of Arkansas Division of Agriculture newsroom, and has been tailored for Georgia Tech readers.

Researchers at Georgia Tech, the University of Arkansas System, the University of Nebraska-Lincoln, and Fort Valley State University in Georgia were awarded a $5 million grant to increase use of artificial intelligence and robotics in chicken processing to reduce waste in deboning and detect pathogens.

The grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture will establish the Center for Scalable and Intelligent Automation in Poultry Processing. The center, led by the University of Arkansas System Division of Agriculture, will join researchers from five institutions in three states in efforts to adapt robotic automation to chicken meat processing.

Douglas Britton, manager of the Agricultural Technology Research Program at the Georgia Tech Research Institute (GTRI), said his team was very excited to work on this project with experts at the four other institutions.

“The ultimate goal is to drive transformational innovation into the poultry and meat processing industry through automation, robotics, AI, and VR technologies,” Britton said. “Building on years of work in the GTRI Agricultural Technology Research Program, we are pleased to see that the USDA-NIFA has chosen this team to continue these efforts.”

Georgia Tech is a major partner in the project, and was awarded $2 million to focus on automating the processing lines that turn chickens into meat, said Jeyam Subbiah, professor and head of the food science department for the Division of Agriculture and the Dale Bumpers College of Agricultural, Food and Life Sciences at the University of Arkansas, and director of the project. The grant is for four years.

The Arkansas Agricultural Experiment Station, the research arm of the Division of Agriculture, will receive $2.2 million from the grant primarily to focus on food safety automation for poultry processing plants.

The remaining grant money will be divided between Julia McQuillan, Willa Cather professor of sociology at the University of Nebraska-Lincoln, and Brou Kuoakou, associate dean for research at Fort Valley State University in Georgia.

Jeff Buhr, a USDA Agricultural Research Service scientist, will contribute his expertise in broiler physiology to guide robotic deboning of meat, Subbiah said.

Georgia is the nation’s top broiler producer. Arkansas is number 3, according to 2021 figures from USDA.

Meeting the challenge

The recent impetus to automate chicken processing began with the Covid-19 pandemic, Subbiah said. The illness spread quickly among workers on the processing line. Since the worst of the pandemic, the poultry industry, like many others, has been having trouble hiring enough workers.

“Poultry processing lines began 70 to 80 years ago,” Subbiah said. “Since then, there have been only incremental changes in technology. Today, there’s a need for transformative change.”

Humans can feel when a knife hits a bone. In contrast, existing automation in poultry processing, like deboners, wastes a lot of meat.

“Human deboners leave about 13 percent of meat on the bones,” Subbiah said. “Automated deboners leave 16 to 17 percent. On an industrial scale, that’s a significant loss in value. We will use artificial intelligence and virtual reality to improve precision and reduce wastage.”

Automation can relieve labor shortages, Subbiah said. It also allows plants to locate in rural areas with a smaller labor force but nearer poultry houses and with lower property costs.

Initially, people working remotely may help advance robotic processing. Subbiah envisions workers logging on from home with virtual-reality goggles and haptics gloves to control robots located miles away.

While working remotely, the labor force will teach artificial intelligence how to cut up chickens of varying sizes and shapes.

“Automated machines right now are programmed to debone or cut up chickens based on an average size and shape. But no chicken is that size or shape,” Subbiah said. “Robot-wielded knives cut meat poorly. The machines have to learn how to adjust to the reality of random sizes and shapes.”

Georgia Tech’s participating scientists are all part of GTRI:

- Douglas Britton, manager of the Agricultural Technology Research Program

- Colin Trevor Usher, senior research scientist and branch head of robotics systems and technology, Agricultural Technology Research Program

- Ai-Ping Hu, principal research engineer, Agricultural Technology Research Program

- Konrad Ahlin, research engineer, Intelligent Sustainable Technologies Division

- Michael Park, research engineer, Intelligent Sustainable Technologies Division

- Benjamin Joffe, research scientist, Intelligent Sustainable Technologies Division

- Shreyes Melkote, the Morris M. Bryan, Jr. Professorship in Mechanical Engineering, associate director of the Georgia Tech Manufacturing Institute and executive director of the Novelis Innovation Hub

“We are thrilled to partner with our colleagues here in the Division of Agriculture, as well as our colleagues at Georgia Tech and the other participating institutions on this exciting project,” said David Caldwell, head of the Division of Agriculture’s poultry science department and director of the Center of Excellence for Poultry Science.

“We expect the findings from these coordinated research projects will be impactful for our stakeholders in the commercial poultry industry here in Northwest Arkansas and throughout the entire industry,” Caldwell said. “This project will help keep moving technology forward in processing and food safety of poultry.”

For more information about the project, see the original press release on the University of Arkansas Division of Agriculture website.

News Contact

Catherine Barzler, Senior Research Writer and Editor

Mar. 09, 2023

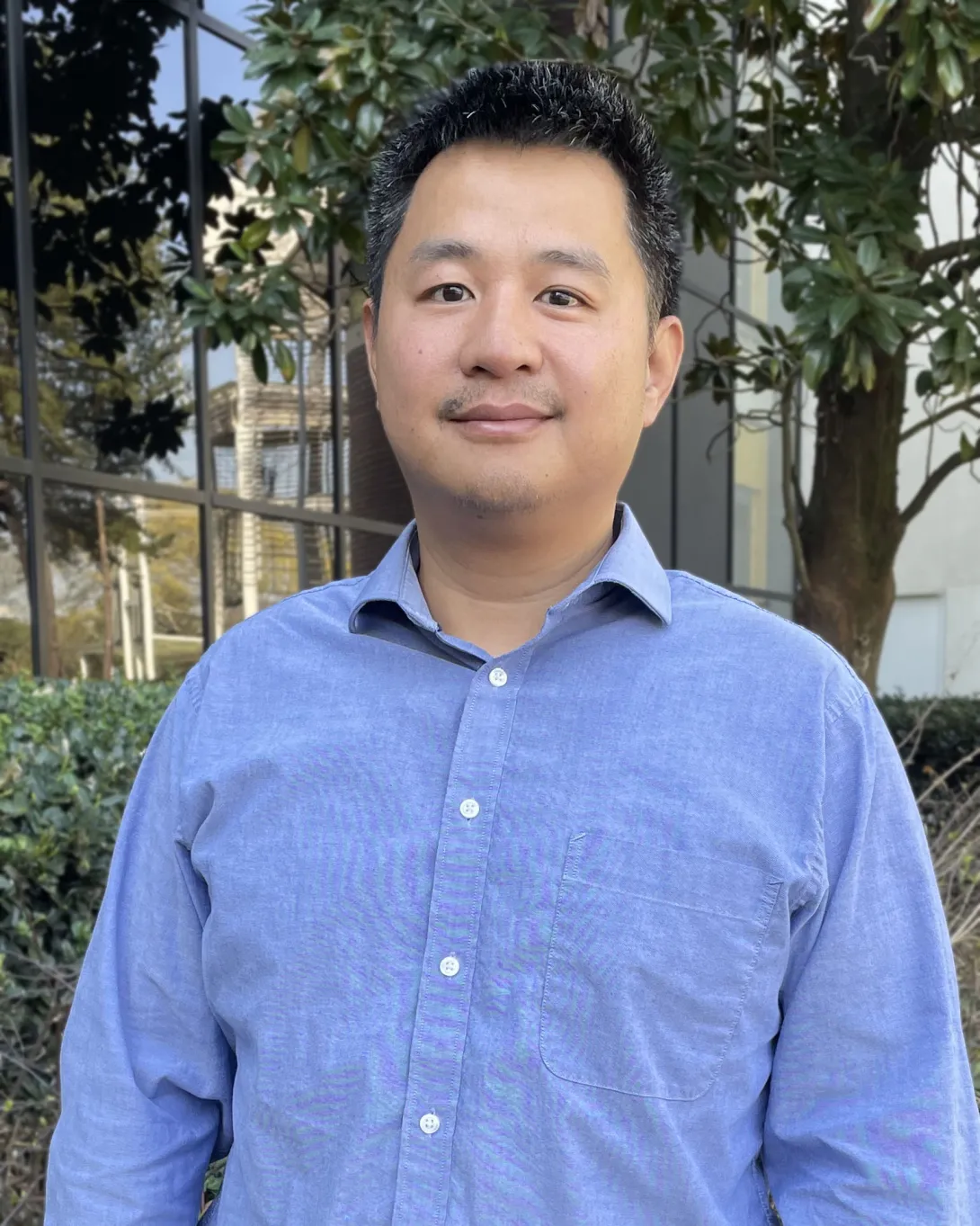

Kan (Kevin) Wang, senior research engineer, in the Georgia Tech Manufacturing Institute (GTMI) was selected to be part of the Research Faculty Teaching Fellows Program (Fall 2023/Spring 2024). The program aims to enhance the interaction across the Institute’s teaching and research activities. It offers research faculty the opportunity to become first-time instructors, and for those who have taught in the past, the ability to turn their cutting-edge research programs into instructional programs that enhance the teaching missions in the academic units.

Wang proposed a new course, Resilience of Biomanufacturing Supply Chains, which won his placement into the program.

“This Research Faculty Teaching Fellows Program will allow me to introduce important research topics in my research area to more Industrial Systems and Engineering (ISyE) students,” said Wang. “Case studies developed in my research projects and presented in the course will show students how to apply the knowledge learned from this course in actual industrial scenarios.”

Wang is also hoping that this teaching opportunity could help him better organize his own knowledge and research ideas in this area, and lead to new ideas that may develop into new collaborations between him and ISyE faculty. These collaborations could result in new research proposals and/or peer-reviewed papers. Plus, students taking his course would be provided opportunities to join new research projects in his lab.

According to Wang, cell therapy manufacturing is a nascent industry that will have critical workforce needs in five to ten years. He wants to expose more industrial engineering students into this emerging new industry.

News Contact

Mar. 02, 2023

Ryan Lawler realized early on in her academic career that a scientist with a great idea can potentially change the world.

“But I didn’t realize the role that real estate can play in that,” said Lawler, general manager of BioSpark Labs – the collaborative, shared laboratory environment taking shape at Science Square at Georgia Tech.

Sitting adjacent to the Tech campus and formerly known as Technology Enterprise Park, Science Square is being reactivated and positioned as a life sciences research destination. The 18-acre site is abuzz with new construction, as an urban mixed-use development rises from the property.

Meanwhile, positioned literally on the ground floor of all this activity is BioSpark Labs, located in a former warehouse, fortuitously adjacent to the Global Center for Medical Innovation. It’s one of the newer best-kept secrets in the Georgia Tech research community.

BioSpark exists because the Georgia Tech Real Estate Office, led by Associate Vice President Tony Zivalich, recognized the need of this kind of lab space. Zivalich and his team have overseen the ideation, design, and funding of the facility, partnering with Georgia Advanced Technology Ventures, as well as the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University, and the core facilities of the Petit Institute for Bioengineering and Bioscience.

“We are in the middle of a growing life sciences ecosystem, part of a larger vision in biotech research,” said Lawler, who was hired on to manage the space, bringing to the job a wealth of experience as a former research scientist and lab manager with a background in molecular and synthetic biology.

Researchers’ Advocate

BioSpark was designed to be a launch pad for high-potential entrepreneurs. It provides a fully equipped and professionally operated wet lab, in addition to a clean room, meeting and office space, to its current roster of clients, five life sciences and biotech startup, a number certain to increase – because BioSpark is undergoing a dramatic expansion that will include 11 more labs (shared and private space), an autoclave room, equipment and storage rooms.

“We want to provide the necessary services and support that an early-stage company needs to begin lab operations on day one,” said Lawler, who has put together a facility with $1.7 million in lab equipment. “I understand our clients’ perspective, I understand researchers and their experiments, and their needs, because I have first-hand proficiency in that world. So, I can advocate on their behalf.”

CO2 incubators, a spectrophotometer, a biosafety cabinet, a fume hood, a -80° freezer, an inverted microscope, and the autoclave are among the wide range of apparatus. Plus, a virtual treasure trove of equipment is available to BioSpark clients off-site through the Core Facilities of the Petit Institute for Bioengineering and Bioscience on the Georgia Tech campus.

“One of the unique things about us is, we’re agnostic,” Lawler said. “That is, our startups can come from anywhere. We have companies that have grown out of labs at Georgia State, Alabama State, Emory, and Georgia Tech. And we have interest from entrepreneurs from San Diego, who are considering relocating people from mature biotech markets to our space.”

Ground Floor Companies

Marvin Whiteley wants to help humans win the war against bacteria, and he has a plan, something he’s been cooking up for about 10 years, which has now manifested in his start-up company, SynthBiome, one of the five startups based at BioSpark Labs.

“We can discover a lot of antibiotics in the lab but translating them into the clinic has been a major challenge – antibiotic resistance is the main reason,” said Whiteley, professor in the School of Biological Sciences at Georgia Tech. “Something might work in a test tube easily enough and it might work in a mouse. But the thing is, bacteria know that mice are different - and and so bacteria act differently in mice than in humans.”

SynthBiome was built to help accelerate drug discovery. With that goal in mind, Whiteley and has team set out to develop a better, more effective preclinical model. “We basically learned to let the bacteria tell us what it’s like to be in a human,” Whiteley said. “So, we created a human environment in a test tube.”

Whiteley has said a desire to help people is foundational to his research. He wants to change how successful therapies are made. The same can be said for Dr. Pooja Tiwari, who launched her company, Arnav Biotech, to develop mRNA-based therapeutics and vaccines. Arnav Biotech also serves as a contract researcher and manufacturer, helping other researchers and companies interested in exploring mRNA in their work.

“There are only a handful of people who have deep knowledge of working in mRNA research, and this limits the access to it” said Tiwari, a former postdoctoral researcher at Georgia Tech and Emory. “We’d like to democratize access to mRNA-based therapeutics and vaccines by developing accessible and cost-effective mRNA therapeutics for global needs”.

Arnav – which has RNA right there in the name – in Sanskrit means ‘ocean.’ An ocean has no discernible borders, and Tiwari is working to build a biotech company that eliminates borders in equitable access to mRNA-based therapeutics and vaccines.

With this mission in mind, Arnav is developing mRNA-based, broad-spectrum antivirals as well as vaccines against pandemic potential viruses before the next pandemic hits. Arnav has recently entered in a collaboration with Sartorius BIA Separations, a company based on Slovenia, to advance their mRNA pipeline. While building its own mRNA therapeutics pipeline, Arnav is also helping other scientists explore mRNA as an alternative therapeutic and vaccine platform through its contract services.

“I think of the vaccine scientist who makes his medicine using proteins, but would like to explore the mRNA option,” Tiwari posits. “Maybe he doesn’t want to make the full jump into it. That’s where we come in, helping to drive interest in this field and help that scientist compare his traditional vaccines to see what mRNA vaccines looks like.”

She has all the equipment and instruments that she needs at BioSpark Labs and was one of the first start-ups to put down roots there. So far, it’s been the perfect partnership, Tiwari said, adding, “It kind of feels like BioSpark and Arnav are growing up together.”

News Contact

Writer: Jerry Grillo

Feb. 09, 2023

Coral reef conservation is a steppingstone to protect marine biodiversity and life in the ocean as we know it. The health of coral also has huge societal implications: reef ecosystems provide sustenance and livelihoods for millions of people around the world. Conserving biodiversity in reef areas is both a social issue and a marine biodiversity priority.

In the face of climate change, Annalisa Bracco, professor in the School of Earth and Atmospheric Sciences at Georgia Institute of Technology, and Lyuba Novi, a postdoctoral researcher, offer a new methodology that could revolutionize how conservationists monitor coral. The researchers applied machine learning tools to study how climate impacts connectivity and biodiversity in the Pacific Ocean’s Coral Triangle — the most diverse and biologically complex marine ecosystem on the planet. Their research, recently published in Nature Communications Biology, overcomes time and resource barriers to contextualize the biodiversity of the Coral Triangle, while offering hope for better monitoring and protection in the future.

“We saw that the biodiversity of the Coral Triangle is incredibly dynamic,” Bracco said. “For a long time, it has been postulated that this is due to sea level change and distribution of land masses, but we are now starting to understand that there is more to the story.”

Connectivity refers to the conditions that allow different ecosystems to exchange genetic material such as eggs, larvae, or the young. Ocean currents spread genetic material and also create the dynamics that allow a body of water — and thus ecosystems — to maintain consistent chemical, biological, and physical properties. If coral larvae are spread to an ecoregion where the conditions are very similar to the original location, the larvae can start a new coral.

Bracco wanted to see how climate, and specifically the El Niño Southern Oscillation (ENSO) in its phases — El Niño, La Niña, and neutral conditions — impacts connectivity in the Coral Triangle. Climate events that move large masses of warm water in the Pacific Ocean bring enormous changes and have been known to exacerbate coral bleaching, in which corals turn white due to environmental stressors and become vulnerable to disease.

“Biologists collect data in situ, which is extremely important,” Bracco said. “But it’s not possible to monitor enormous regions in situ for many years — that would require a constant presence of scuba divers. So, figuring out how different ocean regions and large marine ecosystems are connected over time, especially in terms of foundational species, becomes important.”

Machine Learning for Discovering Connectivity

Years ago, Bracco and collaborators developed a tool, Delta Maps, that uses machine learning to identify “domains,” or regions within any kind of system that share the same dynamic. Bracco initially used it to analyze domains of climate variability in models but also suspected it could be used to study ecoregions in the ocean.

For this study, they used the tool to map out domains of connectivity in the Coral Triangle using 30 years of sea surface temperature data. Sea surface temperatures change in response to ocean currents over scales of weeks and months and across distances of tens of kilometers. These changes are relevant to coral connectivity, so the researchers built their machine learning tool based on this observation, using changes in surface ocean temperature to identify regions connected by currents. They also separated the time periods that they were considering into three categories: El Niño events, La Niña events, and neutral or “normal” times, painting a picture of how connectivity was impacted during major climate events in particular ecoregions.

Novi then applied a ranking system to the different ecoregions they identified. She used rank page centrality, a machine learning tool that was invented to rank webpages on the internet, on top of Delta Maps to identify which coral ecoregions were most strongly connected and able to receive the most coral larvae from other regions. Those regions would be the ones most likely sustain and survive through a bleaching event.

Climate Dynamics and Biodiversity

Bracco and Novi found that climate dynamics have contributed to biodiversity because of the way climate introduces variability to the currents in the equatorial Pacific Ocean. The researchers realized that alternation of El Niño and La Niña events has allowed for enormous genetic exchanges between the Indian and Pacific Oceans and enabled the ecosystems to survive through a variety of different climate situations.

“There is never an identical connection between ecoregions in all ENSO phases,” Bracco said. “In other parts of the world ocean, coral reefs are connected through a fixed, often small, number of ecoregions, and if you eliminate this fixed number of connections by bleaching all connected reefs, you will not be able to rebuild the corals in any of them. But in the Pacific the connections are changing all the time and are so dynamic that soon enough the bleached reef will receive larvae from completely different ecoregions in a different ENSO phase.”

They also concluded that, because of the Coral Triangle’s dynamic climate component, there is more possibility for rebuilding biodiversity there than anywhere else on the planet. And that the evolution of biodiversity in the Coral Triangle is not only linked to landmasses or sea levels but also to the evolution of ENSO through geological times. The researchers found that though ENSO causes coral bleaching, it has helped the Coral Triangle become so rich in biodiversity.

Better Monitoring Opportunities

Because coral reef survival has been designated a priority by the United Nations Sustainable Development Goals, Bracco and Novi’s research is poised to have broad applications. The researchers’ method identified which ecoregions conservationists should try hardest to protect and also the regions that conservationists could expect to have the most luck with protection measures. Their methodology can also help to identify which regions should be monitored more and the ones that could be considered lower priority for now due to the ways they are currently thriving.

“This research opens a lot of possibilities for better monitoring strategies, and especially how to monitor given a limited amount of resources and money,” Bracco said. “As of now, coral monitoring often happens when groups have a limited amount of funding to apply to a very specific localized region. We hope our method can be used to create a better monitoring over larger scales of time and space.”

CITATION: Novi, L., Bracco, A. “Machine learning prediction of connectivity, biodiversity and resilience in the Coral Triangle.” Commun Biol 5, 1359 (2022).

News Contact

Catherine Barzler, Senior Research Writer/Editor

Feb. 06, 2023

Researchers at the Georgia Tech Research Institute (GTRI) are using additive manufacturing techniques to create unique waveguide structures that would be difficult or impossible to make using conventional fabrication processes. The new techniques are especially useful for integrating updated components into equipment that might otherwise require significant design changes.

In high-powered millimeter wave and microwave radars and antennas, waveguides direct electromagnetic energy from one component to another inside the equipment. Until recently, the waveguides had been fabricated from extruded copper or aluminum tubing, but these traditional manufacturing techniques can’t always accommodate the complex configurations needed for optimal design with minimal energy transmission losses.

“To propagate electromagnetic waves efficiently, the waveguide must have a very precise internal geometry,” explained GTRI Senior Research Engineer Kyle Azevedo. “Yet, the waveguide must also be very smooth in terms of its internal surface finish. The cavity that transmits the energy has to be very well controlled to avoid significant losses. And the waveguides must also fit into confined spaces.”

Additive Techniques Offer Specific RF Advantages

To allow more complex designs, GTRI researchers are evaluating two alternative fabrication techniques: 3D-printed structures fabricated from metal and 3D-printed polymer components that are metal coated. Each has advantages and disadvantages and must be chosen for the specific application. The researchers are testing waveguides made using both techniques for mechanical performance in resisting fatigue damage, thermal performance in dissipating heat, electrical performance – and their RF energy loss.

Flexibility afforded by additive techniques can help designers accommodate waveguides within a crowded design that includes many other components. In one current project, the researchers found that they needed to move a radar’s feed horn several inches to accommodate other design considerations. But that complicated the waveguide design.

“That was a really big challenge, because we had to change some of the existing waveguides, and we couldn’t do that with traditional tubing pieces that were available without coming up with a whole new design,” Azevedo said. “But by using additive processes that allow more customization, we were able to make things smaller and optimize the design in a single iteration.”

In another project – in consideration for use on Army counter-battery radar – researchers at U.S. Army DEVCOM C5ISR Center used additive techniques to accommodate an updated component of a different size and shape than the original to improve RF performance. The researchers designed a 3D-printed waveguide that accommodated the existing connectors and integrated into its legacy systems, then worked with the Army’s Rock Island Arsenal to optimize fabrication and quality control. That new component was successfully tested at Tobyhanna Army Depot and Yuma Proving Ground, and is now being evaluated as an OEM alternative. This may allow additive manufacturing to augment the supply system.

In addition to facilitating designs that might otherwise have been more challenging, the GTRI researchers expect additive manufacturing will allow them to accelerate the iterative development of prototypes by moving some waveguide fabrication in-house.

Overcoming Challenges with New Fabrication Methods

For all-metal waveguides, additive manufacturing can have some disadvantages, but those may not be as significant as they might first appear. To limit transmission losses, inside surfaces of conventional waveguides are smooth, but because of the way metal 3D printing works, smooth internal surfaces can be difficult to fabricate. The design flexibility of additive processes can make up for that.

“In one of our designs, we found that even though we might have some limitations on the roughness of the surface finish, we could gain back the transmission losses by optimizing the waveguide shape,” Azevedo explained. “The final design would not have been possible using traditional waveguide fabrication techniques.”

Though applying metal coatings to waveguides produced from polymers or resins can provide smoother surfaces, this process comes with its own set of challenges.

“One of the issues we are tackling now is that a lot of the resins and polymers that have desirable properties for plating contain silica,” said Max Tannenbaum, a GTRI research engineer. “They are ceramic-like when cured, but when you remove the resin, a lot of the conventional solvents don’t remove the silica, and you end up with a chalky powder on the surface. If you can’t remove that before you try to plate it, the plating won’t adhere.”

Building a Knowledge Base for RF Applications of Additive Processes

To support expanded applications for waveguides fabricated using additive techniques, the researchers are using both simulation and experimentation to develop comprehensive design information.

“The traditional method for making waveguides has been around since World War II, when the original systems got up and running, and those techniques have been refined over the decades since then,” said Azevedo. “As a result, there’s a wealth of detailed data on what works, including the metallurgic properties. We want to develop a comparable depth of understanding for the new additive manufacturing techniques that offer so many advantages.” By putting together what they have learned, the research team plans to share their knowledge with other RF engineers who may be interested in the additive approaches.

“Our effort is focusing on two parallel paths: looking at the mechanical constraints involved with fabrication and the RF limitations,” said GTRI Research Engineer Austin Forgey. “We are merging the new experimental data we’re getting with RF simulations, and combining that with testing mechanical properties. That will give us a full design package that can be used by the designers who need it.”

Beyond waveguides, the GTRI researchers are working on other applications of additive manufacturing to RF design. With researchers in Georgia Tech’s School of Mechanical Engineering, they are fabricating cold plates that are 3D printed from aluminum and used to cool high-powered electronics. The 3D printing allows novel fluid flow in a single part, not possible with conventional fabrication.

Similarly, they are also looking at additive techniques to make shielding needed to protect components from electromagnetic interference.

While they expect to expand their use of additive fabrication approaches to provide new design options for RF applications, the researchers don’t see additive manufacturing doing away with conventional fabrication techniques any time soon.

“My opinion is that there will certainly be a mix because additive manufacturing techniques aren’t the answer for everything,” said Tannenbaum. “But they are solutions to a lot of specific problems that we encounter, allowing us to build parts that are cheaper, lighter, and available more quickly.”

Writer: John Toon

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia USA

About GTRI: The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,800 employees, supporting eight laboratories in over 20 locations around the country and performing more than $700 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, the state, and industry. For more information, please visit www.gtri.gatech.edu.

News Contact

(Interim) Director of Communications

Michelle Gowdy

Michelle.Gowdy@gtri.gatech.edu

404-407-8060

Jan. 30, 2023

Becky Francosky is the Director of Air Service Development at Hartsfield-Jackson Atlanta International Airport (ATL). She has more than 15 years of experience in strategic planning, market research, analytics and project management that has been refined in roles in both the private and public sector. Ms. Francosky has broad experience in conducting primary and secondary research, analyzing market and competitive intelligence, gap analysis, forecasting and leveraging analytical frameworks to develop forward-looking and extrapolative insights.

Becky rejoined Hartsfield-Jackson in 2022 after working extensively with ATL on several key analytical studies through her company Advanced Aviation Analytics. While in her consulting role, she worked on a variety of projects including the Economic Impact Study, management dashboards and frameworks for gate utilization and forecasting. She has recruited several international passenger and cargo airlines and frequently engages with current and prospective airlines to help build stakeholder engagement.

Additionally, Becky plans and coordinates economic and business development activities with a variety of state and local organizations. From 2008 to 2012, Becky directed the market research program to understand customer’s preferences and needs, which led to expanded product and service offerings and increased non-aeronautical revenue by 40 percent.

We are very excited to have Becky join our board, lend us her expertise, and continue ATL's participation and support of SCL programs.