May. 26, 2022

Multiple members of the School of Electrical and Computer Engineering (ECE) contributed to the four-year project.

Georgia Institute of Technology has been named the EcoCAR Mobility Challenge Year Four champion by the U.S. Department of Energy (DOE). Tech’s award-winning interdisciplinary team consists of approximately 60 undergraduate and graduate students from the College of Engineering, College of Computing, Scheller College of Business, and Georgia State University.

Eleven North American university EcoCAR teams gathered for the final challenge in Arizona from May 9-20, 2022. The event marked the culmination of the competition, which tasked the universities with applying propulsion system electrification, autonomous driving control, and vehicle-to-infrastructure connectivity, to improve the energy efficiency of a 2019 Chevrolet Blazer while maintaining safety, utility, and consumer acceptability.

Over the four-year competition — sponsored by the DOE, General Motors (GM) and MathWorks — each team transformed its vehicle from a design concept into a reality. The final year of competition challenged teams to test, prove, and refine their work from the previous three years, mimicking a real-world automotive product development cycle.

ECE professor David Taylor is a faculty advisor for Georgia Tech’s EcoCAR team, along with professors Michael Leamy in the George W. Woodruff School of Mechanical Engineering (ME), and Thomas Fuller in the School of Chemical and Biomolecular Engineering (ChBE).

“The role of ECE in this competition is significant, ranging from powertrain electrification to driving automation. Our team’s vehicle excelled in these areas, winning the events concerned with energy consumption and autonomous operation,” said Taylor. “The EcoCAR program provides valuable experiences for ECE students because the real-world challenges of the project effectively supplement classroom learning.”

Georgia Tech’s EcoCAR team is a $1 million research program housed under Georgia Tech’s Vertically Integrated Projects (VIP) Program. VIP allows undergraduate and graduate students to participate in ambitious, long-term, multidisciplinary project teams that are led by faculty. The VIP program originated in ECE under the leadership of professor Edward Coyle.

ECE graduate research assistant (GRA) Nicholas Hummel played a key leadership role on the team along with fellow GRA Nishan Nekoo in ME. Both Hummel and Nekoo received their master’s degrees this spring. Hummel also gave the first-place presentation on Connected and Automated Vehicle Systems with recent ECE bachelor’s degree graduate Joyce Zhao.

“I've been on the team for the past two years, and have seen it come from a nearly fully virtual format at the beginning of the pandemic to the success we've achieved this year,” said Hummel, who led the team’s driving automation efforts. “If I had not joined this team, I would never have had the opportunity to grow so much as a leader and increase my passion for automation and robotics.”

Additionally, recent ECE bachelor’s degree graduate Braeden Dickson, along with recent ME bachelor’s degree graduate Anna Cobb, gave the first-place presentation on Propulsion Controls and Modeling. Braeden worked on powertrain controls to convert the conventional Chevy Blazer to a hybrid electric vehicle architecture. With his efforts, Georgia Tech vehicle was the only vehicle of the competition to improve energy consumption over the stock Blazer.

Read more about the award-winning team, view pictures from the finale, and learn about future plans.

News Contact

Dan Watson

dwatson@ece.gatech.edu

May. 04, 2022

Finalists for the position of executive director of the Georgia Tech Manufacturing Institute (GTMI) will be delivering vision presentations during the week of May 9. The candidates have been asked to present their vision for GTMI, perspectives on how to build a strong GTMI community that supports and develops its staff and researchers from across the Institute, and to take questions from the Georgia Tech community. The schedule for these sessions is shown below along with the in-person location, Microsoft Teams link for the virtual option. Biographical information for the candidates is provided below. A post-presentation survey link was sent internally via email to portions of the GT community.

Wednesday, May 11 at 12:00p

Tom Kurfess - Callaway building, 813 Ferst Drive, NW, Room 114 or link here for virtual participation

Thursday, May 12 at 2:00p

Chuck Zhang – Callaway building, 813 Ferst Drive, NW, Room 114 or link here for virtual participation

- - - - - - Short Bios - - - - -

Tom Kurfess

Wednesday, May 11 at 12:00p

Callaway building, 813 Ferst Drive, NW, Room 114

Virtual option - link here

Thomas R. Kurfess is the HUSCO/Ramirez Distinguished Chair in Fluid Power and Motion Control and Professor of Mechanical Engineering at Georgia Tech. He received his S.B., S.M. and Ph.D. degrees in mechanical engineering from M.I.T. in 1986, 1987 and 1989, respectively. He also received an S.M. degree from M.I.T. in electrical engineering and computer science in 1988. During 2019-2021 he was on leave serving as the Chief Manufacturing Officer at Oak Ridge National Laboratory (ORNL), where he was responsible for strategic planning for ORNL in advanced manufacturing. He was also and was the Founding Director for the Manufacturing Science Division at ORNL. During 2012-2013 he served as the Assistant Director for Advanced Manufacturing at the Office of Science and Technology Policy in the Executive Office of the President of the United States of America, where he was responsible for coordinating Federal advanced manufacturing R&D. He was President of SME in 2018, and currently serves on the Board of Governors of the ASME. His research focuses on the design and development of advanced manufacturing systems targeting secure digital manufacturing, additive and subtractive processes, and large-scale production enterprises. He is a member of the National Academy of Engineering and is a Fellow of ASME, AAAS, and SME.

Chuck Zhang

Thursday, May 12 at 2:00p

Callaway building, 813 Ferst Drive, NW, Room 114

Virtual option link here

Dr. Chuck Zhang is a Harold E. Smalley Professor in the H. Milton Stewart School of Industrial & Systems Engineering at Georgia Tech. He is also an affiliated faculty member with Georgia Tech Manufacturing Institute (GTMI). He serves as the Director of the newly established Center for Composite and Hybrid Materials Interfacing (CHMI) which is a three-university NSF Industry/University Cooperative Research Center (IUCRC) headquartered in GTMI. Dr. Zhang’s current research interests include advanced composite/nanocomposite structures manufacturing and maintenance, additive manufacturing, bio-manufacturing, and manufacturing cybersecurity. As PI and Co-PI, he has led or conducted over 50 research projects sponsored by numerous federal agencies including Department of Defense, Department of Veterans Affairs, Food and Drug Administration, National Institute of Standards and Technology and National Science Foundation, as well as industrial companies such as ATK, Cummins, Delta Air Lines, and Lockheed Martin. He currently serves as a Co-lead of the “Soft Robotics Technology Working Group” for NextFlex, one of the Manufacturing USA Network Institutes. Dr. Zhang is a fellow of Institute of Industrial and Systems Engineers (IISE). He has published over 220 refereed journal articles and 230 conference papers. He also holds 26 U.S. patents.

News Contact

Walter Rich

Apr. 29, 2022

WASHINGTON, April 22, 2022 – The U.S. Department of Energy (DOE), General Motors and MathWorks announced the 15 North American universities and the 2023 Cadillac LYRIQ as the vehicle selected for the EcoCAR EV Challenge, the next DOE-sponsored Advanced Vehicle Technology Competition (AVTC) set to begin in Fall 2022.

Georgia Tech has earned a spot as one of the 15 universities to participate in this prestigious series. “This year, the selection process was highly competitive due to the number of outstanding applications we received from universities, big and small, across the U.S and Canada,” said Kristen Wahl, Director of the Advanced Vehicle Technology Competition (AVTC) Program at Argonne National Laboratory. “We are pleased to announce that Georgia Tech will be competing in the EcoCAR EV Challenge and we are excited to see what the teams will accomplish in supporting the country’s transition to clean energy and electric vehicles.”

Managed by Argonne National Laboratory, the EcoCAR EV Challenge will be at the cutting edge of automotive engineering education, serving as a proving ground for future automotive engineers. The four-year competition will challenge students to engineer a next-generation battery electric vehicle (BEV) that deploys connected and autonomous vehicle (CAV) features to implement energy efficient and customer-pleasing features, while meeting the decarbonization needs of the automotive industry.

“Georgia Tech is elated to be accepted into the EcoCAR EV Challenge, which marks our third consecutive Advanced Vehicle Technology Competition (AVTC). Georgia Tech’s participation in multiple AVTCs has significantly enriched the hands-on learning and training opportunities valued by our students, faculty, and administration. We greatly appreciate the financial and technical support provided by the headline sponsors, to include the U.S. Department of Energy, General Motors, and the Mathworks. With the new vehicle platform being an electric vehicle, and with an increased emphasis on diversity, equity, and inclusion, Georgia Tech looks forward to renewing our participation in one of the premier vehicle competitions in the United States.” Dr. Raheem Beyah, Dean, College of Engineering & Southern Company Chair at Georgia Institute of Technology.

Georgia Tech students will work on the EcoCAR Challenge through a Vertically Integrated Projects (VIP) class, which is led by Woodruff School professors Antonia Antoniou and Michael Leamy, and School of Electrical and Computer Engineering professor David Taylor. The project is open to students of all majors and levels of experience with an emphasis on computer engineering, electrical engineering, mechanical engineering, management, and computer science.

“In addition to the technical skills they acquire working on the EcoCAR Challenge, students gain valuable teamworking and project management skills, which prepare them well for a career in the automotive industry,” said Professor Michael Leamy. “We are thrilled to be selected to continue our participation in this incredible program.”

General Motors will donate a 2023 Cadillac LYRIQ to each team, challenging them to design, build, refine, and demonstrate the potential of their advanced propulsion systems and CAV technologies over four competition years. Teams will be tasked with complex, real-world technical challenges including enhancing the propulsion system of their LYRIQ to optimize energy efficiency while maintaining consumer expectations for performance and driving experience.

More than $6M will be provided to the selected universities, including four Minority Serving Institutions, funding students to pursue advanced mobility research and experiential learning and supporting the recruitment and retention of underrepresented minority students and faculty to help build an EV talent pipeline that reflects the diversity of North America.

To improve diversity in STEM and higher education, diversity, equity, and inclusion will be incorporated into all areas of the competition. Teams will be challenged to identify and address specific equity and electrification issues in mobility through the application of innovative hardware and software solutions, outreach to underserved communities and underrepresented youth to increase awareness about advanced mobility and recruit underrepresented minorities into STEM fields. Four Minority Serving Institutions, including two Historically Black Colleges and Universities (HBCUs), will also share more than $1M to strengthen their automotive programs and recruit and retain underrepresented minority students and faculty.

The universities selected to participate in the EcoCAR EV Challenge include:

- Embry-Riddle Aeronautical University/ Bethune-Cookman University

- Georgia Institute of Technology

- Illinois Institute of Technology

- McMaster University (Canada)

- Mississippi State University

- Ohio State University / Wilberforce University

- University of Alabama

- University of California, Riverside

- University of California, Davis

- University of Texas at Austin

- University of Waterloo (Canada)

- Virginia Tech

- West Virginia University

“Argonne has managed the Advanced Vehicle Technology Competitions program for DOE in partnership with the auto industry for more than three decades. The EcoCAR EV Challenge will build upon the program’s rich history to provide North America’s premier training ground for future EV engineers. Academia and Industry both recognize the role of experiential learning in helping to prepare students for the rapidly evolving automotive workforce,” said Wahl.

These universities will build student teams with multi-disciplinary engineering skill sets, such as Mechanical, Electrical, Computer, and Software engineering. The teams will also engage students from various other backgrounds such as Communications, PR, Business and Project Management to emulate the real-world experience of working in the automotive industry. This cross-disciplinary approach is critical to success in EcoCAR and also prepares students for successful careers in the mobility sector.

The competition will kick off in Fall 2022 and conclude in May 2026. For more information, please visit ecocarevchallenge.org or avtcseries.org.

About EcoCAR EV Challenge:

EcoCAR EV Challenge is a four-year collegiate engineering program that builds on the successful 34-year history of Department of Energy Advanced Vehicle Technology Competitions (AVTC) that exemplify the power of government/industry partnerships in addressing our nation’s toughest energy and mobility challenges and providing invaluable practical skills of promising young minds ready to enter the workforce.

The EcoCAR EV Challenge is managed by Argonne National Laboratory and sponsored by the U.S. Department of Energy, General Motors, and MathWorks as the headlining sponsors.

General Motors provides each of the competing teams with a Cadillac LYRIQ – the brand’s first all-electric vehicle built on GM’s Ultium Platform which encompasses a common set of propulsion components – battery cells, modules, packs and a family for Ultium Drive units. GM also provides vehicle components, seed money, technical mentoring and operational support.

A foundational principle of EcoCAR is the use of Model-Based Design, a mathematical and visual design approach using MATLAB and Simulink that enables users to manage projects quickly and cost-effectively, collaborate on designs, and develop complex embedded systems. MathWorks provides teams with a full suite of software tools, simulation models, training, technical mentoring and operational support.

The U.S. Department of Energy and its research and development facility, Argonne National Laboratory, provide competition management, team evaluation and logistical support. Other sponsors provide hardware, software and training.

# # #

Reference to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not constitute or imply the U.S. Department of Energy’s endorsement, recommendation, or favoring by the U.S. Government or any agency thereof. The Department of Energy’s role in this competition does not include the solicitation or selection of sponsorships, nor does it include the establishment of sponsorship criteria.

News Contact

Dan Watson

dwatson@ece.gatech.edu

Apr. 27, 2022

By Frida Carrera

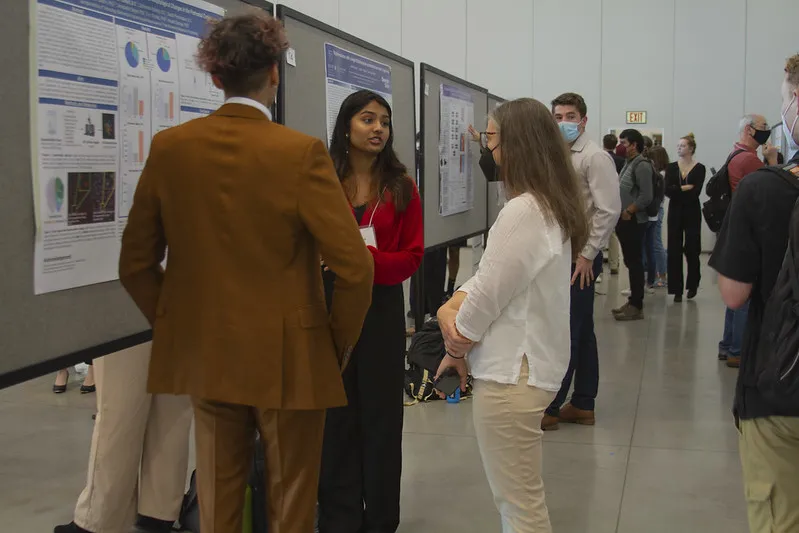

On Wednesday, April 13th 2022, the Undergraduate Research Opportunities Program (UROP) hosted the 16th annual Spring Undergraduate Research Symposium. UROP’s annual symposium is Georgia Tech’s largest undergraduate research colloquium and allows students to present their research and gain valuable skills and presentation experience. Each year the symposium also presents awards to the top poster and oral presentation from each college and honors the Outstanding Undergraduate Researcher (OUR) from each college. And with over 40 oral presentations and nearly 90 poster presentations, this year’s symposium proved to be another success for UROP and Georgia Tech.

This year the symposium was held in Exhibition Hall and opened with an introduction and keynote address to students, faculty, and other non-presenters. Shortly after, the event moved into the poster presentations segment where undergraduate students displayed their research to judges, faculty, and other attendees. The oral presentations followed soon after and gave student researchers the opportunity to go more in-depth with their research and findings and answer any questions the judges and attendees had. To end the event, sponsoring colleges and departments recognized Outstanding Undergraduate Researchers from their respective colleges. Additionally, the symposium judges were tasked with selecting the top student researchers having exceptional poster and oral presentations.

Any Georgia Tech undergraduate student interested in presenting their research is encouraged to apply for future symposiums and to build on research presentation skills, connect with other undergraduate researchers and faculty, and the chance to be recognized with awards by members of the Georgia Tech research community. UROP also hosts other research-related events and workshops throughout the school year to assist undergraduate students interested in research and build on their passions!

To view the list of awardees and pictures from the event visit: https://symposium.urop.gatech.edu/awards/

To learn more about undergraduate research at Georgia Tech visit: https://urop.gatech.edu/

Apr. 26, 2022

The Georgia Tech Manufacturing Institute (GTMI) hosted an open house to celebrate the launch of the Georgia Manufacturing 4.0 Consortium. The event took place inside Georgia Tech’s Advanced Manufacturing Pilot Facility (AMPF) on April 14, 2022. The 20,000 square foot research and development facility is located on Georgia Tech’s campus.

AMPF open house activities included an informational session, tour, equipment demos, and networking reception. Attendees from more than 45 companies learned how to engage with the Georgia manufacturing community through workforce development programs, technology pilot programs, and research activities to innovate and accelerate secure integration of Industry 4.0 technologies into Georgia manufacturing.

The newly created Georgia 4.0 Manufacturing Consortium is an industry-academia-government consortium that advances and deploys manufacturing technologies into the market. By leveraging the latest in manufacturing developments and technologies, consortium members have unique opportunities to compete more effectively to become global leaders.

“Georgia Tech’s AMPF provides a world-leading proving grounds for developing, de-risking, and piloting new manufacturing technologies to make them ready for commercial adoption,” said Aaron Stebner, associate professor in the Woodruff School and Mechanical Engineering, and School of Materials Science and Engineering. “AMPF was enabled through Georgia Tech’s manufacturing research partnerships with Boeing and Delta. In it’s first two years, the mission has expanded to include collaboration with more than a dozen companies. Establishing the Georgia Manufacturing 4.0 Consortium provides a vehicle to include dozens more companies in each of the future years, with emphasis on growing the participation of small businesses supported through grant subsidies.”

The consortium will conduct research, offer workforce training, provide small manufacturers with the ability to use advanced manufacturing tools, gain information to drive product and material changeovers, innovate new products, provide economic diversification, accelerate product development cycles, and adopt Industry 4.0 technologies.

Georgia Tech’s AMPF was created by a $3 million gift from the Delta Air Lines Foundation and was intentionally designed as a flexible space that can house future manufacturing innovation projects of almost all types, from additive/hybrid manufacturing to composites, digital manufacturing/industry 4.0, and industrial robotics. Current AMPF industry partners range from aerospace and automotive companies to materials manufacturing companies.

The AMPF is a flagship component of the Georgia Tech Manufacturing Institute and is a special, reconfigurable R&D high bay manufacturing facility where companies work alongside researchers and students to take early-stage concepts from idea to reality. With each new project and innovation, AMPF is where the factory of the future is being envisioned and created.

The Georgia 4.0 Manufacturing Consortium was created with funding from the Department of Defense (DOD) Office of Local Defense Community Cooperation. This DOD office helps states and communities strengthen critical relationships with Department of Defense’s assets and installations. Small businesses (less than 100 employees) will be able to receive discounted consortium membership rates as a result of this DOD grant funding. While DOD funded the consortium, companies outside of the defense industry are also welcome to be part of the consortium.

“Creating a valuable advanced manufacturing pilot facility and holding this industry-focused open house has been a long-term key goal. Our new governance structure is allowing AMPF to incorporate industry partners as members of AMPF along with the establishment of this new consortium for small and medium companies to join at a discounted rate,” said George White, director for strategic partnerships in the Office of the Vice President for Interdisciplinary Research.

“I also want to thank Ben Wang, executive director of the Georgia Tech Manufacturing Institute, for his strong, unwavering support to build AMPF. With Ben’s support, we’ve been able to build a world-class R&D pilot facility to advance manufacturing technology and solve problems for a variety of industry partners over many years—and will continue to do so for many other industry partners.”

Companies interested in joining the Georgia 4.0 Manufacturing Consortium can contact George White or Aaron Stebner at Georgia Tech.

News Contact

Walter Rich

Apr. 07, 2022

The SecureAmerica Institute (SAI) and the Advanced Robotics for Manufacturing (ARM) Institute are partnering with Georgia Tech to investigate how robotics and automation in manufacturing can enhance the resiliency, flexibility, and competitiveness of U.S. industrial base supply chains, thanks to a $5 million grant award from the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST).

The project plans to create the Robotics and Automation Decision Framework for Agility and Resilience (RADAR). This framework will allow small and medium-sized manufacturers (SMMs) to systemically evaluate the cost-to-benefit ratio of integrating robotics and automation for aiding the response to supply chain disruptions due to public health crises like COVID-19 and additional economic threats.

“The RADAR end-to-end supply chain framework encompasses macro-scale and micro-scale modeling, along with physical demonstration, by bringing together interdisciplinary capabilities of elite partners from SAI and ARM — including the Texas Manufacturing Assistance Center, Georgia Institute of Technology, General Electric, Deloitte, and Morgan State University — to serve the requirements set by NIST,” said Eleftherios Lakovou, Ph.D., SAI’s manufacturing supply chain director and principal investigator on the project.

He sees the award as an exciting and potent validation of the unique footprint SAI has established and a way for the institute to provide innovative solutions to national priorities.

“The project is particularly valuable because it empowers SMMs, who form the backbone of the nation’s industrial base,” Lakovou continued. “Small manufacturers often lack the scale and human capital needed to increase their use of automation and robotics to position themselves favorably in the sophisticated, next-generation, cost-competitive, agile and resilient supply chains of America’s future.”

“We are delighted to work with the team at the SecureAmerica Institute on this important project,” said Arnie Kravitz, chief innovation officer at the ARM Institute. “Our work will help smaller manufacturers make better decisions in the face of the current and future pandemics.”

The Georgia Tech team will contribute to this initiative by providing already developed and validated supply chain simulation software and extending it to stress test supply chains so that small manufacturers can be better informed of what risks their supply chains might face, how these risks can be mitigated, and what role robotics and automation can play as a source of supply chain productivity and risk mitigation.

RADAR’s funding is provided by the American Rescue Act and is part of a larger $54 million initiative by NIST to award high-impact projects for pandemic response research and development across eight manufacturing institutes in the Manufacturing USA network.

News Contact

Walter Rich

Apr. 07, 2022

ECE Ph.D. student Nujhat Tasneem has won the Ed Nicollian Award for best student paper at the Institute of Electrical and Electronics Engineers (IEEE) Semiconductor Interface Specialist Conference (SISC). The event was held in early December 2021 with awards being announced in March 2022.

Tasneem’s presentation, “Charge Trapping Effects on Memory Window in Ferroelectric Field Effect Transistors,” was the highest rated presentation based on the feedback of SISC committee members and invited speakers. She is the first Georgia Tech student to receive the award.

The award-winning paper introduced a novel electrical characterization method to track carrier capture and emission dynamics during write operations in n-type ferroelectric-field-effect transistors (FEFETs). FEFETs are a candidate for high-density, non-volatile, embedded memory applications due to their promise of having low operating voltages and write energies combined with low-leakage, and high-density integration. While significant work has been done to explain the operation and endurance of FEFETs, this research details a superior method of measurement because it provides an understanding of the transport and the status of the ferroelectric.

“This novel characterization method sheds a light on the underlying device physics of FEFETs, which is necessary to optimize its design, especially as a non-volatile memory (NVM) element” said Tasneem.

Tasneem is currently part of the The Khan Lab headed by ECE Assistant Professor Asif Khan. The work presented was supported by the ASCENT project (Applications and Systems-driven Center for Energy-Efficient integrated Nano Technologies), one of six centers supported by SRC’s Joint University Microelectronics Program (JUMP). Fabrication at Tech was done at the Institute for Electronics and Nanotechnology (IEN), supported by the National Science Foundation- National Nanotechnology Coordinated Infrastructure (NSF-NNCI) program.

The SISC Ed Nicollian Award for best student paper was established in 1995 in honor of Professor E.H. Nicollian, University of North Carolina at Charlotte. Nicollian was a pioneer in the exploration of the metal-oxide-semiconductor system, particularly in the area of electrical measurements. His efforts were fundamental to establishing the SISC in its early years.

News Contact

Dan Watson

dwatson@ece.gatech.edu

Mar. 29, 2022

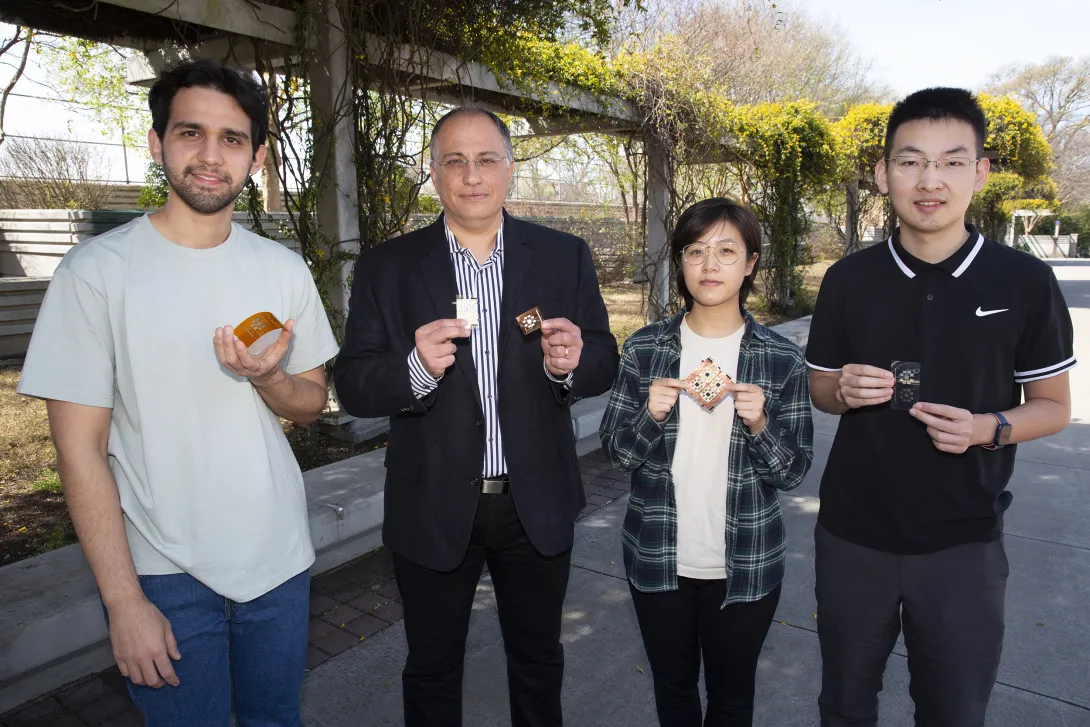

5G+ (5G/Beyond 5G) is the fastest-growing segment and the only significant opportunity for investment growth in the wireless network infrastructure market, according to the latest forecast by Gartner, Inc. But currently 5G+ technologies rely on large antenna arrays that are typically bulky and come only in very limited sizes, making them difficult to transport and expensive to customize.

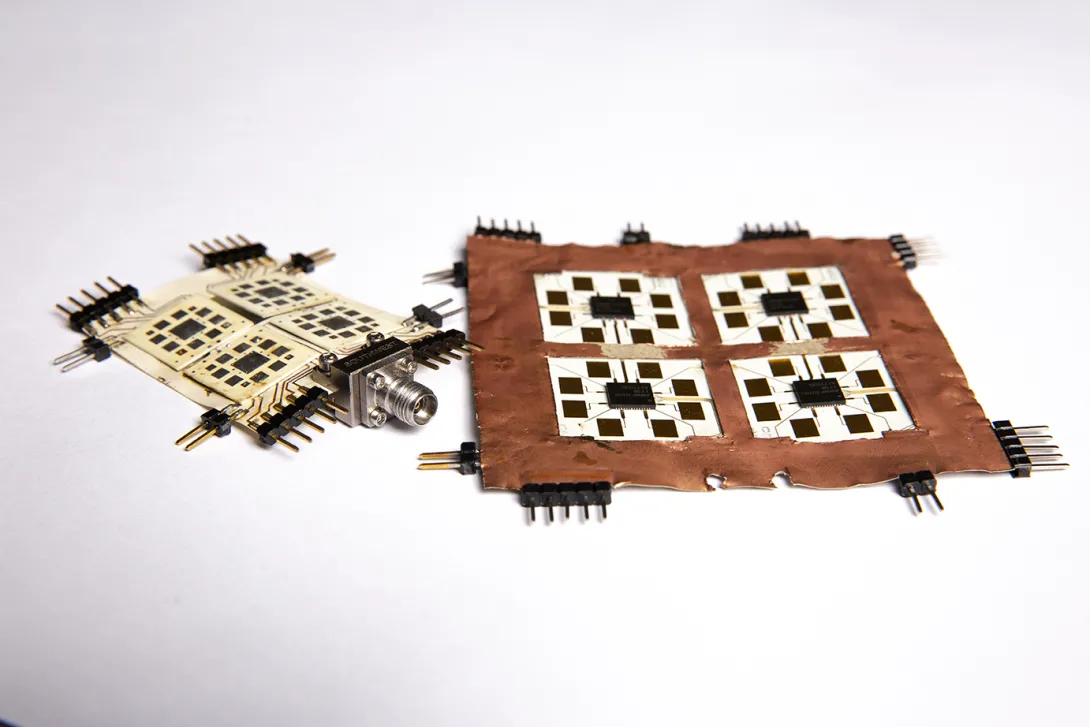

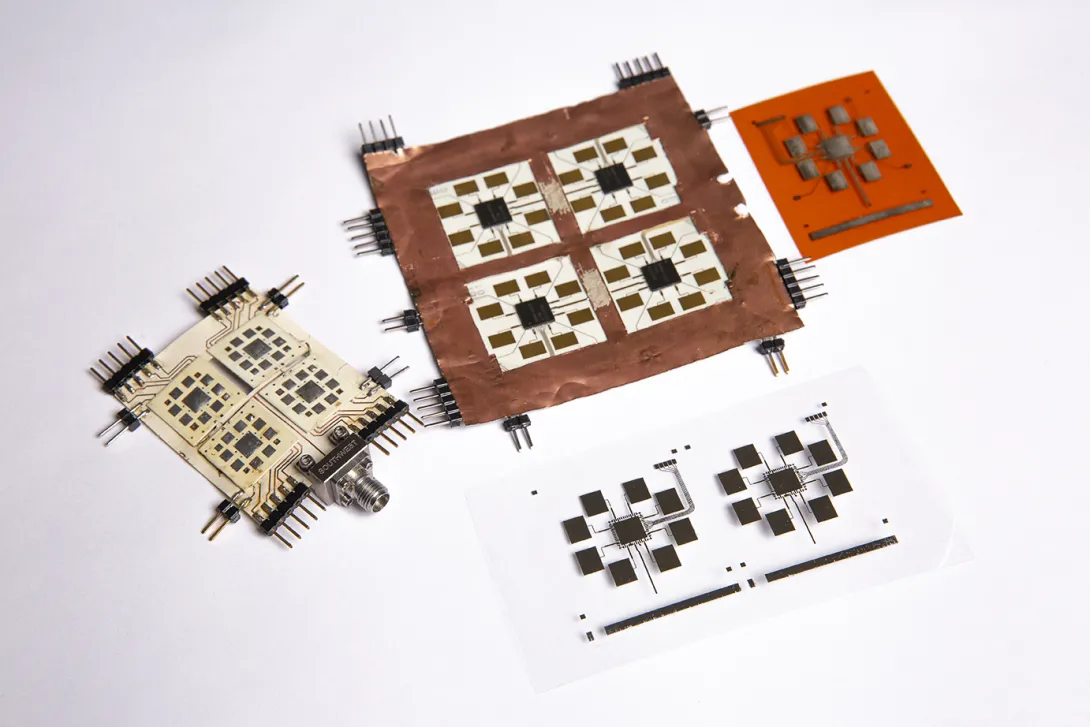

Researchers from Georgia Tech’s College of Engineering have developed a novel and flexible solution to address the problem. Their additively manufactured tile-based approach can construct on-demand, massively scalable arrays of 5G+ (5G/Beyond 5G)‐enabled smart skins with the potential to enable intelligence on nearly any surface or object. The study, recently published in Scientific Reports, describes the approach, which is not only much easier to scale and customize than current practices, but features no performance degradation whenever flexed or scaled to a very large number of tiles.

“Typically, there are a lot of smaller wireless network systems working together, but they are not scalable. With the current techniques, you can’t increase, decrease, or direct bandwidth, especially for very large areas,” said Manos Tentzeris, Ken Byers Professor in Flexible Electronics in the School of Electrical and Computer Engineering. “Being able to utilize and scale this novel tile-based approach makes this possible.”

Tentzeris says his team’s modular application equipped with 5G+ capability has the potential for immediate, large-scale impact as the telecommunications industry continues to rapidly transition to standards for faster, higher capacity, and lower latency communications.

BUILDING THE TILES

In Georgia Tech’s new approach, flexible and additively manufactured tiles are assembled onto a single, flexible underlying layer. This allows tile arrays to be attached to a multitude of surfaces. The architecture also allows for very large 5G+ phased/electronically steerable antenna array networks to be installed on-the-fly. According to Tentzeris, attaching a tile array to an unmanned aerial vehicle (UAV) is even a possibility to surge broadband capacity in low coverage areas.

In the study, the team fabricated a proof-of-concept, flexible 5×5-centimeter tile array and wrapped it around a 3.5-centimeter radius curvature. Each tile includes an antenna subarray and an integrated, beamforming integrated circuit on an underlying tiling layer to create a smart skin that can seamlessly interconnect the tiles into very large antenna arrays and massive multiple-input multiple-outputs (MIMOs) — the practice of housing two or more antennas within a single wireless device. Tile-based array architectures on rigid surfaces with single antenna elements have been researched before, but do not include the modularity, additive manufacturability, or flexible implementation of the Georgia Tech design.

The proposed modular tile approach means tiles of identical sizes can be manufactured in large quantities and are easily replaceable, reducing the cost of customization and repairs. Essentially, this approach combines removable elements, modularity, massive scalability, low cost, and flexibility into one system.

5G+ IS JUST THE BEGINNING

While the tiling architecture has demonstrated the ability to greatly enhance 5G+ technologies, its combination of flexible and conformal capabilities has the potential to be applied in numerous different environments, the Georgia Tech team says.

“The shape and features of each tile scale can be singular and can accommodate different frequency bands and power levels,” said Tentzeris. “One could have communications capabilities, another sensing capabilities, and another could be an energy harvester tile for solar, thermal, or ambient RF energy. The application of the tile framework is not limited to communications.”

Internet of Things, virtual reality, as well as smart manufacturing/Industry 4.0 — a technology-driven approach that utilizes internet-connected “intelligent” machinery to monitor and fully automate the production process — are additional areas of application the team is excited to explore.

“The tile-architecture’s mass scalability makes its applications particularly diverse and virtually ubiquitous. From structures the size of dams and buildings, to machinery or cars, down to individual health-monitoring wearables,” said Tentzeris. “We’re moving in a direction where everything will be covered in some type of a wireless conformal smart skin encompassing electronically steerable antenna arrays of widely diverse sizes that will allow for effective monitoring.”

The team now looks forward to testing the approach outside the lab on large, real-world structures. They are currently working on the fabrication of much larger, fully inkjet-printed tile arrays (256+ elements) that will be presented at the upcoming International Microwave Symposium (IEEE IMS 2022) – the flagship IEEE conference in RF and microwave engineering. The IMS presentation will introduce a new tile-based large-area architecture version that will allow assembly of customizable tile arrays in a rapid and low-cost fashion for numerous conformal platforms and 5G+ enabled applications.

****

The authors declare no competing interests.

This work was supported in part by the National Science Foundation.

CITATIONS: He, X., Cui, Y. & Tentzeris, M.M. Tile-based massively scalable MIMO and phased arrays for 5G/B5G-enabled smart skins and reconfigurable intelligent surfaces. Sci Rep 12, 2741 (2022). https://doi.org/10.1038/s41598-022-06096-9

K.Hu, G.S.V.Angulo, Y.Cui and M.M.Tentzeris, “Flexible and Scalable Additively Manufactured Tile-Based Phased Arrays for Satellite Communications and 5G mmWave Applications,” accepted for presentation at IEEE International Microwave Symposium (IMS) 2022, Denver, CO, June 2022.

News Contact

Dan Watson

dwatson@ece.gatech.edu

Mar. 24, 2022

The Georgia Tech Manufacturing Institute (GTMI) has initiated a search for a the position of Executive Director. The Executive Director provides intellectual leadership and organizational oversight for GTMI. This person will build the manufacturing research portfolio of Georgia Tech by serving as an advocate for research engagement with companies, state and federal government agencies, and other entities within Georgia Tech. As a service-oriented leader, they work with researchers and staff to develop collaborations and initiatives; proactively prepare and coordinate preparation of major research grant applications; build communities of interest across campus; cultivate thought leadership; educate key stakeholders and prepare the future workforce; increase the profile of Georgia Tech and its research community; and otherwise attract research partners to Georgia Tech.

GTMI's mission is to convene industry leaders, government partners and top researchers to collaborate on the grand challenges facing the U.S. manufacturing industry today: accelerating technology development and deployment, creating quality jobs, ensuring global competitiveness, and advancing economic and environmental stability. GTMI moves innovations from the lab to the market, spanning the entire innovation value chain, from raw materials and recycled resources to prototypes and finished products. These efforts include the development of materials, systems, processes, education, and policies that impact the manufacturing marketplace.

Nominations and Applications

All nominations should be directed in confidence to the search committee chair or any member of the search committee. To access the application:

1. Log into OneUSG. You will land on the Employee Self Service Page.

2. Select the Recruiting Self Service Tile, then go to the Recruiting Self Service Page.

3. Click on ‘Apply For Jobs’ tile, then Click on ‘View all jobs’ option.

4. At the top in the search bar type ‘240914’ and press enter

Interested candidates would submit the following application materials:

1. A cover letter not to exceed two pages that summarizes the candidate’s qualifications, includes a brief statement of their vision for GTMI, and articulates their commitment to DEI initiatives

2. A curriculum vitae

3. The names and contact information for three references

While applications and nominations will be received until the Executive Director is selected, interested parties are encouraged to respond by April 4, 2022 at 9 am EDT, to assure full consideration.

News Contact

Walter Rich

Mar. 18, 2022

By Frida Carrera

During the summer of 2021, computer science student Neil Sanghavi and computer science recent grad Ahan Shah, both from Fairfax, VA, reconnected to catch up with one another and discuss the projects they were working on. In doing so they discovered a mutual resolve to create something using innovative technology and solve a problem relating to intellectual property, specifically patents. Both Neil and Ahan had just started to get into crypto trading and realized that NFT technology had more to offer than its collectible aspect. Here the idea of PatentX was created: to use NFT technology to provide utility in an antiquated space that lacked efficiency.

“It is estimated that we have $1 trillion in unused IP in the United States currently. Additionally, it is reported that there is $25.6 billion worth of patent monetization available today. This is why we created PatentX, a blockchain-backed marketplace to facilitate intellectual property transactions. We built this to make sure the little man innovators and entrepreneurs have an outlet to monetize and connect their patents with the world. Not only that, we are creating tools for large businesses, law firms, venture capitals to manage all of their IP on the blockchain that can handle transactions in seconds.”

Neil and Ahan describe their product launch process as a great learning experience and are firm believers that there can never be too much help. They are currently supported by DXPartners and have received help from various mentors and blockchain professionals. They have been able to traverse obstacles and learn about the marketing, finance, and business aspects behind building a startup despite coming from a technical background.

Their vision for PatentX is to disrupt the traditional way intellectual property is being transacted and to become the World’s Next Web3 Patent Office. PatentX will be releasing an NFT collection of the most historic patent innovations this early March and encourage interested individuals to stay tuned for their launch.

To learn more about PatentX visit their social media:

Twitter: @PatentXNFT

Instagram: @PatentX.io

To learn more about student innovation at Georgia Tech visit: https://innovation.cae.gatech.edu/