Dec. 16, 2021

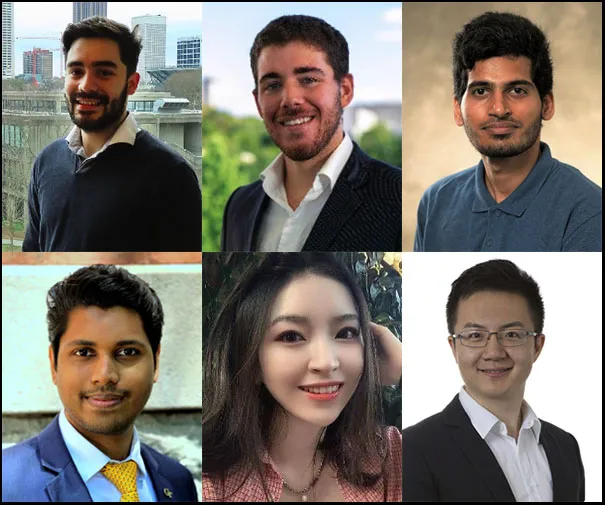

The Novelis scholars program review committee at the Georgia Institute of Technology received 34 nominations and selected six graduate students as the inaugural group of Novelis Scholars for the 2021-2022 academic year. The winning scholars are:

- Andrés Felipe Castro Méndez, a third-year Ph.D. student in the School of Materials Science and Engineering. His research focuses on understanding the formation thermodynamics of lead halide perovskites deposited by thermal co-evaporation.

- Carlos Fernández, a Ph.D. student in the Woodruff School of Mechanical Engineering. His research interests are in reactor design and computational methods for efficient electrochemical CO2 conversion to high-value fuels.

- Rupesh Kumar Mahendran, a second year Ph.D. student in the Woodruff School of Mechanical Engineering. His research is focused on physics-based and data-driven model development for shape-memory alloy (SMA) alloy, manufacturing, and part design, including developing high throughput methodology and surrogate models to accelerate SMA developments.

- Rupesh Rajendran, a Ph.D. student in the School of Materials Science & Engineering. His research is focused on understanding the effects of post-processing treatments and microstructure on corrosion, stress corrosion cracking, and mechanical behavior of additively manufactured (AM) 7xxx series aluminum alloys for aerospace applications.

- Tingli Xie, a Ph.D. student in the Woodruff School of Mechanical Engineering. Her research areas of interest are deep learning, uncertainty quantification and fault diagnosis. The goal of her research is to develop intelligent computational methods to provide accurate diagnosis of key faults by fusing multiple sensor resources in manufacturing systems.

- Wei Yang, who is pursuing a Ph.D. degree in machine learning and a M.S. degree in statistics in the H. Milton Stewart School of Industrial and Systems Engineering. His research interest is on high dimensional data analysis for process monitoring and diagnosis using functional profiles, images and videos with applications in manufacturing and energy sectors.

The Novelis Innovation Hub at Georgia Tech announced the launch of the Novelis Scholars Program during fall 2021. The program seeks to recognize and cultivate top graduate students conducting research in various aspects of sustainability, high-throughput materials discovery, surface functionalization, and artificial intelligence (AI)/data science applications in materials, manufacturing, and supply chain technology.

Novelis has partnered with Georgia Tech to collaborate on research and development, and promote the education of the next generation of engineers dedicated to making better products that lead to a more sustainable world. Novelis is headquartered in Atlanta with a global footprint, over 12,500 employees, and recorded $12.3 billion in revenue for its 2020 fiscal year. Novelis recently expanded its research partnership with Georgia Tech.

The Novelis Innovation Hub expects to issue its next call for Novelis Scholars for the 2022‐2023 Academic Year in Spring/early Summer 2022.

News Contact

Walter Rich

Dec. 16, 2021

The global supply chain has been rocked by disruptions triggered largely by the coronavirus pandemic, resulting in a cascade of shortages on a host of products ranging from computer chips to medications.

But supply chain disruptions also highlight the potential vulnerabilities in the U.S. manufacturing sector’s critical segments like defense.

To help manufacturers across the state, the Georgia Institute of Technology has launched the Georgia Manufacturing 4.0 Consortium to work with those businesses in defense and related industries become more resilient and less susceptible to supply chain disruptions. The Consortium, which will begin accepting members in April 2022, will work with Georgia defense manufacturers to incorporate cybersecurity protocols, smart technologies such as sensor packs, machine learning, artificial intelligence, and other best practices under Industry 4.0 technology standards.

Led by Aaron Stebner, associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, the Consortium is an 18-month pilot funded by a Department of Defense Office of Local Defense Community Cooperation (OLDCC) grant of nearly $1 million. Georgia Tech is working in partnership with Spelman College, the Technical College System of Georgia, and the Georgia Department of Economic Development, under the grant to develop workforce, training manuals, a curriculum, and to support businesses in adapting to economic and technological changes that emerge at a much more rapid pace today.

“It’s a cooperative effort that’s really focused on helping to get modern technologies to these Georgia manufacturers. This is about establishing a community of manufacturers who all want to move forward but don’t have the bandwidth or capabilities do it individually,” Stebner said.

The Consortium has three goals. The first is to increase the manufacturing defense supply chain’s resilience and diversification. That will allow those companies to pivot quickly in response to demand and let non-defense-related industries enter the supply chain at critical junctures. The second goal is to work with Georgia manufacturers in adopting new technologies and address challenges that put those businesses at risk.

Lastly, the Consortium is to be a conduit that helps small- and medium-sized manufacturers test out innovations using Georgia Tech resources such as the Advanced Manufacturing Pilot Facility, connect manufacturers with each other, and potentially unlock new markets and collaboration opportunities.

While the focus is on defense manufacturing, the Consortium is open to all manufacturers.

“We want to help as many manufacturers as we can, to grow a bigger pie that helps everybody, lowers risk, and allows companies to be part of building innovative solutions” Stebner said.

Manufacturing Supports Georgia Economy

National Association of Manufacturers data show that manufacturing accounts for $61.1 billion in economic activity, roughly 10% of Georgia’s total output. The industry includes more than 6,600 firms that employ nearly 400,000.

At $14 billion a year, Georgia is ranked 13th in federal defense spending. Roughly 1,200 manufacturers in the state are in defense or related industries. Those include information technology companies that support cybersecurity, wireless communications, and other innovations that are critically essential to Industry 4.0 in defense manufacturing.

University partners from the Technical College System of Georgia and Spelman College will look to take the Consortium findings and data from the work they do with member companies to create educational programming and workforce training.

Today, there is a need for more workers in machine learning and other aspects of advanced manufacturing, as well as a need to change perceptions of manufacturing, especially in rural parts of the state, Stebner explained.

To that end, the Technical College System of Georgia could develop programming for students within its two-year education curriculum. It also has a mobile manufacturing unit that could be taken to rural parts of the state and used as a tool to highlight opportunities in manufacturing and dispel misconceptions about the industry.

The all-women’s Spelman College, one of the nation’s premier historically black colleges and universities, launched an extended reality program in the fall of 2020. That program aims to integrate art, technology, and narrative on a gaming platform which is familiar and engaging for students. Those students will develop the technical skills to develop games, create immersive virtual experiences, and develop visual simulations for research, education, and training.

For Consortium members, Spelman’s extended reality program can be used to help turn research data gathered from them into workforce training and development modules.

“Spelman has a long history of graduating women in the natural sciences, and that history has recently led the Department of Defense to distinguish the College as a Center of Excellence for educating women in STEM,” said Jerry Volcy, a Spelman professor and co-director of the Spelman Innovation Lab.

The extended reality program furthers Spelman’s goal to increase the technological readiness of its graduates.

“Spelman has a long record of forging pathways for women of color into new spaces. Today, these spaces include extended reality, defense and, to some extent, manufacturing research,” Volcy said. “From the College’s perspective, participation in the Consortium has the dual potential of creating and discovering new pathways into these industries while immediately providing real-world applications laboratory for the developing extended reality program.”

Fulfilling Georgia Tech’s Mission

Within Georgia Tech, the Georgia Manufacturing Extension Partnership and the Georgia Tech Manufacturing Institute will support Consortium efforts.

The Consortium reflects Georgia Tech’s broader mission to further its Advanced Manufacturing Initiative, said George White, Georgia Tech’s interim vice president of Industry Collaboration.

“The anticipated research impact envisioned through the Defense Manufacturing Consortium will strengthen Georgia Tech’s positioning in enabling major public private collaborations,” White said. “The advent of the Consortium represents the opportunity to convene key stakeholders from government, academics, and industry to innovate and solve the most challenging problems in manufacturing.”

News Contact

Writer and media relations contact:

Péralte C. Paul

peralte.paul@comm.gatech.edu

404.316.1210

Dec. 14, 2021

The Georgia Institute of Technology was awarded a grant from the U.S. Department of Commerce’s Economic Development Administration (EDA) as part of its $1 billion Build Back Better Regional Challenge. Georgia Tech is one of 60 entities to be awarded funding to assist communities nationwide in their efforts to accelerate the rebuilding of their economies in the wake of the pandemic.

As a leader in artificial intelligence, manufacturing research, and innovation-led economic development, Georgia Tech will utilize the grant for technical assistance to plan the Georgia Artificial Intelligence Manufacturing Corridor (GA-AIM). Led by Thomas Kurfess and Aaron Stebner in the George W. Woodruff School of Mechanical Engineering and in collaboration with local partners, GA-AIM will fill existing technology gaps, build a technological opportunity framework that includes underrepresented communities and rural Georgia counties, and better secure the state’s manufacturing infrastructure.

Georgia Tech’s partners in the effort include the Russell Innovation Center for Entrepreneurs, Spelman College, the Technical College System of Georgia, and the Georgia Department of Economic Development.

“We are truly honored to be awarded this grant to implement our vision for manufacturing excellence in Georgia with our partners in artificial intelligence research,” said Chaouki T. Abdallah, executive vice president for Research at Georgia Tech. “Alongside these important partners, the grant enables us to collaborate to include diverse backgrounds and perspectives in the process of learning, discovery, and creation, furthering Georgia Tech’s mission to expand access.”

Georgia Tech and its partners will pair artificial intelligence and manufacturing research innovation to better secure the manufacturing ecosystem, expand opportunity to distressed and rural communities and underrepresented groups, and support business growth across the state.

“We are thrilled to help communities work together — in coalitions of government, nonprofits, academia, the private sector, and others — to craft ambitious and regionally unique plans to rebuild their communities,” said Alejandra Y. Castillo, assistant secretary of commerce for the EDA. “These projects will help revitalize local economies and tackle our biggest challenges related to climate change, manufacturing, supply chains, and more. EDA is proud to ignite these plans and help communities nationwide build back better.”

GA-AIM’s partners have created a complementary network of resources that focus on each partner organization’s expertise and mission.

“We have an opportunity to create meaningful impact at the intersection of AI and manufacturing,” said Stebner, who wrote the grant proposal that resulted in the $500,000 grant from EDA.

Kurfess, who serves as the regional economic competitiveness officer for the grant, added, “Bringing together AI and manufacturing will ensure a strong manufacturing base for Georgia that will leverage our well-trained workforce and our strong educational institutions that are participating in this effort. What excites me the most is that AI will augment our workforce, making it more valuable and productive, ensuring job growth for Georgia and the U.S. well into the future.”

The GA-AIM effort takes a multifaceted approach to address its core goals:

Georgia Tech

- Formation of the AI Manufacturing Pilot Facility: Georgia Tech’s Advanced Manufacturing Pilot Facility will be transformed into the AI Manufacturing Pilot Facility. The new facility allows for government pilot trials, cybersecurity games, and workforce training to innovate, transition, and create a workforce for AI manufacturing technologies without exposing the region’s supply chains to risk.

- Center for AI Commercialization: Two of Georgia Tech’s commercialization programs — VentureLab and I-Corps South — will create a center for the commercialization of AI manufacturing technologies into local and regional startups. Those commercialization efforts will occur through a quarterly cohort-based entrepreneurial training program built on the National Science Foundation’s I-Corps curriculum. The center will also provide training for instructors to build a sustainable workforce and will secure investment funding for these startups.

- AI Manufacturing Community Engagement: The Enterprise Innovation Institute, Georgia Tech’s chief economic development arm, will engage in focused outreach and technical assistance to small and mid-sized manufacturers and minority business enterprises through its Georgia Manufacturing Extension Partnership and Georgia Minority Business Development Agency Business Center programs. A third Enterprise Innovation Institute program, the Economic Development Lab, will focus on outreach and engagement in distressed and underserved parts of the state, create workforce development programs and implementation strategies, and attract outside investment.

- AI Manufacturing Rural Supply Chain: The Supply Chain and Logistics Institute will study the impact of automation technologies, build automation solutions tailored for rural manufacturers, and create programs that lower the barrier for rural manufacturers’ access to use the AI Manufacturing Pilot Facility.

- AI InVenture K-12 Experiences: To ensure a technically capable workforce in the coming years, Georgia Tech’s InVenture Prize and the Center for Education Integrating Science, Mathematics, and Computing will expand their emphasis to rural and underserved areas of the state by piloting a rural regional event with a region-specific prize. They will also create supplemental lessons centered on AI and data science that will be part of a K-12 InVenture Prize curriculum website.

Spelman College

- Virtual Reality for AI Workforce Training Innovation: Spelman’s Innovation Lab will develop virtual reality technology for training or retraining the GA-AIM workforce to make workers comfortable with new technologies before deployment in real-world applications.

Russell Innovation Center for Entrepreneurs

- LaunchPad AI Innovation Studio: The Russell Innovation Center for Entrepreneurs will create the 5,000-square-foot LaunchPad AI Innovation Studio to provide prototyping and proof of concept development of physical products. Black entrepreneurs will be given access to equipment, training, and mentoring. LaunchPad AI will also be open to AI InVenture teams from Atlanta’s K-12 public schools, with special programs designed for startup mentoring and seed funding for K-12 entrepreneurs.

Technical College System of Georgia (TCSG)

- AI Manufacturing Technical Workforce Development: As Georgia’s technical college coordinating organization, the TCSG will design, develop, and implement curricula at community colleges that include apprenticeships at AI-MPF and virtual reality modules from Spelman. The TCSG will also provide regional entry points for dual enrollment and traditional students to AI manufacturing technical education at certificate and degree levels. Graduates will have exit points that lead directly to careers in the industry or provide for the continuation of education and higher degree attainment through articulation agreements among GA-AIM members.

With this grant, Tech becomes a finalist for significantly more funding to implement projects that support an industry sector and help communities withstand future economic shocks.

“GA-AIM is in strategic alignment with the EDA’s funding priorities, including manufacturing, workforce development, equity, and technology-based economic development,” said David Bridges, vice president of the Enterprise Innovation Institute at Georgia Tech and co-author of the grant proposal. “With manufacturing employing more than 400,000 people across the state and contributing more than $61 billion in economic activity, it’s critical that we leverage the best ideas and programs through our coalition of partners.”

###

About the Georgia Institute of Technology

The Georgia Institute of Technology, or Georgia Tech, is a top 10 public research university developing leaders who advance technology and improve the human condition. The Institute offers business, computing, design, engineering, liberal arts, and sciences degrees. Its nearly 44,000 students, representing 50 states and 149 countries, study at the main campus in Atlanta, at campuses in France and China, and through distance and online learning. As a leading technological university, Georgia Tech is an engine of economic development for Georgia, the Southeast, and the nation, conducting more than $1 billion in research annually for government, industry, and society.

About the U.S. Economic Development Administration

The mission of the U.S. Economic Development Administration (EDA) is to lead the federal economic development agenda by promoting competitiveness and preparing the nation's regions for growth and success in the worldwide economy. An agency within the U.S. Department of Commerce, EDA makes investments in economically distressed communities in order to create jobs for U.S. workers, promote American innovation, and accelerate long-term sustainable economic growth.

Writer: Péralte C. Paul I peralte.paul@comm.gatech.edu I 404.316.1210

Media contact: Steven Norris | stephen.norris@comm.gatech.edu| 404.281.3343

News Contact

Péralte C. Paul

404.316.1210

Dec. 14, 2021

When cell phones, electric vehicle chargers, or other electronic devices get too hot, performance degrades, and eventually overheating can cause them to shut down or fail. In order to prevent that from happening researchers are working to solve the problem of dissipating heat produced during performance. Heat that is generated in the device during operation has to flow out, ideally with little hinderance to reduce the temperature rise. Often this thermal energy must cross several dissimilar materials during the process and the interface between these materials can cause challenges by impeding heat flow.

A new study from researchers at the Georgia Institute of Technology, Notre Dame, University of California Los Angeles, University of California Irvine, Oak Ridge National Laboratory, and the Naval Research Laboratory observed interfacial phonon modes which only exist at the interface between silicon (Si) and germanium (Ge). This discovery, published in the journal Nature Communications, shows experimentally that decades-old conventional theories for interfacial heat transfer are not complete and the inclusion of these phonon modes are warranted.

“The discovery of interfacial phonon modes suggests that the conventional models of heat transfer at interfaces which only use bulk phonon properties are not accurate,” said the Zhe Cheng, a Ph.D. graduate from Georgia Tech’s George W. Woodruff School of Mechanical Engineering who is now a postdoc at University of Illinois at Urbana-Champaign (UIUC). “There is more space for research at the interfaces. Even though these modes are localized, they can contribute to thermal conductance across interfaces.”

The discovery opens a new pathway for consideration when engineering thermal conductance at interfaces for electronics cooling and other applications where phonons are majority heat carriers at material interfaces.

“These results will lead to great progress in real-world engineering applications for thermal management of power electronics,” said co-author Samuel Graham, a professor in the Woodruff School of Mechanical Engineering at Georgia Tech and new dean of engineering at University of Maryland. “Interfacial phonon modes should exist widely at solid interfaces. The understanding and manipulation of these interface modes will give us the opportunity to enhance thermal conductance across technologically-important interfaces, for example, GaN-SiC, GaN-diamond, β-Ga2O3-SiC, and β-Ga2O3-diamond interfaces.”

Presence of Interfacial Phonon Modes Confirmed in Lab

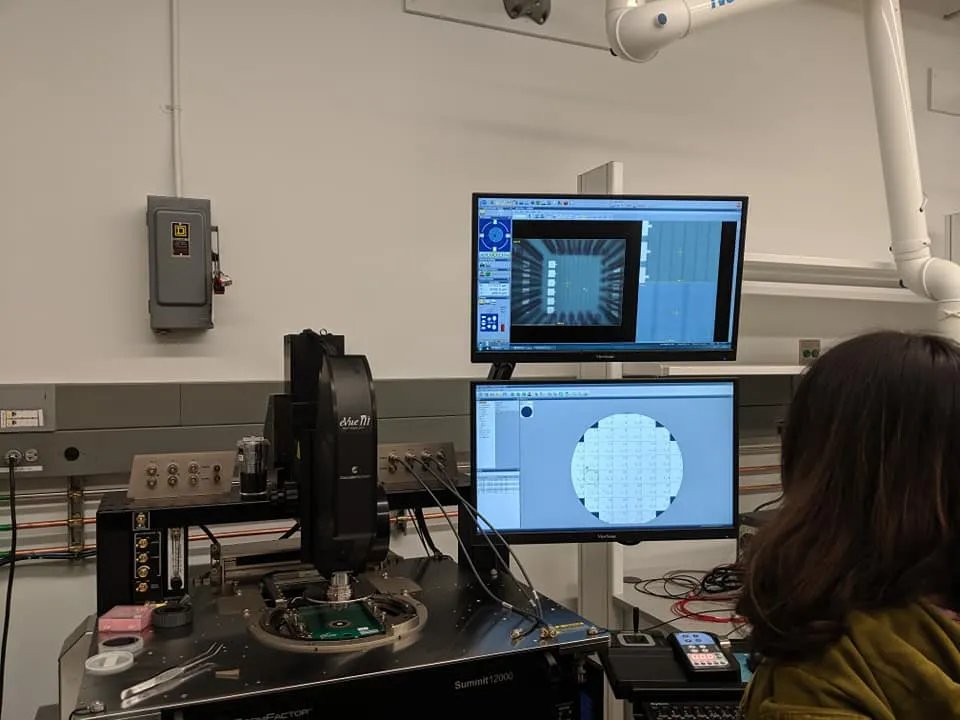

The researchers observed the interfacial phonon modes experimentally at a high-quality Si-Ge epitaxial interface by using Raman Spectroscopy and high-energy resolution electron energy-loss spectroscopy (EELS). To figure out the role of interfacial phonon modes in heat transfer at interfaces, they used a technique called time-domain thermoreflectance in labs at Georgia Tech and UIUC to determine the temperature-dependent thermal conductance across these interfaces.

They also observed a clean additional peak showing up in Raman Spectroscopy measurements when they measured the sample with Si-Ge interface, which was not observed when they measured a Si wafer and a Ge wafer with the same system. Both the observed interfacial modes and thermal boundary conductance were fully captured by molecular dynamics (MD) simulations and were confined to the interfacial region as predicted by theory.

“This research is the result of great team work with all the collaborators,” said Graham. “Without this team and the unique tools that were available to us, this work would not have been possible.”

Moving forward the researchers plan to continue to pursue the measurement and prediction of interfacial modes, increase the understanding of their contribution to heat transfer, and determine ways to manipulate these phonon modes to increase thermal transport. Breakthroughs in this area could lead to better performance in semiconductors used in satellites, 5G devices, and advanced radar systems, among other devices.

The epitaxial Si-Ge samples used in this research were grown at the U.S. Naval Research Lab. The TEM and EELS measurements were done at University of California, Irvine and Oak Ridge National Labs. The MD simulations were performed by the University of Notre Dame. The XRD study was done at UCLA.

This work is financially supported by U.S. Office of Naval Research under a MURI project. The EELS study at UC Irvine is supported by U.S. Department of Energy.

Citation: https://doi.org/10.1038/s41467-021-27250-3

About Georgia Institute of Technology

The Georgia Institute of Technology, or Georgia Tech, is a top 10 public research university developing leaders who advance technology and improve the human condition. The Institute offers business, computing, design, engineering, liberal arts, and sciences degrees. Its nearly 44,000 students representing 50 states and 149 countries, study at the main campus in Atlanta, at campuses in France and China, and through distance and online learning. As a leading technological university, Georgia Tech is an engine of economic development for Georgia, the Southeast, and the nation, conducting more than $1 billion in research annually for government, industry, and society.

Contact:

Ben Wright

Communications Manager

George W. Woodruff School of Mechanical Engineering

ben.wright@me.gatech.edu

Dec. 10, 2021

By Frida Carrera

On December 3, 2021, Startup Exchange presented the Fall 2021 Fellowship Pitch Competition sponsored by the Georgia Tech Student Innovation Program, Office of Undergraduate Education. The event took place at ATL Social Club in Tech Square, a major startup hub situated on Georgia Tech’s campus and perfect for those eager for innovation at GT. The event also welcomed partner companies and recruiters such as NCR and Stord.

At this pitch-style event, six founder teams presented their innovative pitches and competed for first, second, and third place, each with a cash prize to aid in the advancement of their ideas. The first and second place winners of the competition were determined by three guest judges: Kathryn Petralia, co-founder of Kabbage and Drum; Thomas Suarez, co-founder of Teleport and Thiel Fellow; and Evan Jarecki, serial entrepreneur and BM at Startup Atlanta. The event commenced with a brief introduction by Startup Exchange executive board members, followed by presentations from the 6 teams including Fino, InSite, Jargon, and Tokenstack. After hearing each team’s pitch, the judges had time to deliberate and select the top two winners while the audience voted for the People’s Choice winner. Meanwhile, attendees were also able to hear from the partner companies and network while enjoying free perks such as food and beverages.

“There are students everywhere across campus really starting on their start-ups and pursuing their dreams. Atlanta is a growing city and Georgia Tech is the perfect hub for that. These teams, we’re introducing them to entrepreneurship and giving those resources and intro-connections. By doing so, we’re inspiring them in a way. It’s just a great learning experience for them,” explained Startup Exchange’s Director of Fellowship Revanth Tiruveedhi.

Following the intermission, the judges presented the first-place award of $750 to Jargon, a browser extension that points out red flags in user contract agreements, as pitched by team members Kaleb Rasmussen and Devansh Khunteta. Second place of $500 was awarded to Eartheal by team members Colin Burnett, Philip Colt, Neal Austensen, and Brandon Sherrard. People's Choice of $250 was awarded to Tokenstack by team members Nitin Paul, Samrat Sahoo, Yatharth Bhargava, and Mohit Sahoo. The event then closed with remarks by Startup Exchange’s board members and photos with the participants.

To learn more about student innovation at Georgia Tech visit https://innovation.gatech.edu/

Dec. 08, 2021

Supply chain disruptions are not new, but the current disruptions have not only been persistent but have also impacted several industries – and consumers – at the same time. The result has ranged from empty shelves at retail stores to prolonged lead times for consumer products and automobiles.

We sat down with three Georgia Tech Scheller College of Business faculty experts in operations management: Vinod Singhal, Charles W. Brady Chair; Manpreet Hora, associate professor; and Ravi Subramanian, professor. The discussion centered around overarching causes, financial ramifications, and multi-pronged approaches to mitigate the impact of supply chain disruptions in the coming months and year.

1. What caused the supply chain and logistical issues to arise? What effect did Covid-19 play in all of this? Did the influx of stimulus checks and the extension of additional aid to U.S. citizens (rent deferment, etc.) affect the purchase of goods enough to cause the current situation?

All three experts agree there are several factors on both the supply side and the demand side of the supply chain, and logistical challenges that companies and customers are currently facing.

On the supply side, there are issues in global supply chains that are beyond the control of individual companies. A significant one is the congestion at the ports of Los Angeles and Long Beach in the U.S. Nearly 40 percent of imports into the U.S. flow through these two ports. There are stranded containers that have not been unloaded due to labor shortages, limited unloading capacity, and warehouse space constraints.

For example, a CBS news report on November 11, 2021, indicated that at the ports of Los Angeles and Long Beach, about 80 ships carrying more than half a million containers were waiting to unload. Clearing this backlog will take some time. Another related issue that has added to the congestion is the growing number of empty containers that are sitting on ports to be returned back to exporters.

The congestion at ports is being further exacerbated by trucker shortages that could pose a more persistent and long-term challenge for supply chains.

“Moving products from ports to distribution centers, manufacturing plants, and further downstream to retailers was already a concern for many companies even before the pandemic. Now the combination of port congestion and trucker shortage is further delaying the process of bringing products to the right place at the right time,” said Hora.

Shortages of critical components, such as semiconductor chips, have created additional delays for a range of industries. Shutdowns in chip production during the early stages of the pandemic, coupled with increased demand for products such as computers, smartphones, and automobiles has resulted in fierce competition for acquiring chips across industries. For example, the professors noted that during the initial period of the Covid-19 pandemic, semiconductor companies prioritized chip manufacturing to meet the increasing demand for consumer electronics. This, in turn, diverted supply away from automotive production, resulting in substantial delays in cars rolling off assembly lines

The pandemic either amplified the above-mentioned supply chain and logistical issues or brought in unexpected new ones. It necessitated the closure of borders at the national level, and of plants and warehouses at the company level. These closures, in the initial months of the pandemic, followed by new requirements such as social distancing during the opening of facilities affected and slowed down production, warehousing, distribution, and transportation of products.

On the demand side, explained Subramanian, two phenomena occurred that have led to a surge in demand for goods that were already in short supply.

First, during the pandemic, many people were working from home. This curtailed spending on travel, vacations, and demand for experiential goods and services. People had more disposable income, which they diverted to consumer products that were already in short supply.

Second, the global economy and the US, in particular have been turbocharged by trillions of dollars in stimulus during the pandemic. This stimulus, while necessary to deal with the hardships during the pandemic, enhanced the surge in demand for products.

2. Why are some retailers able to deliver goods without an issue?

“Many large retailers, including Walmart Inc., Home Depot Inc., and Target Corp., do not seem to have supply chain and product shortage issues like their counterparts, because they ordered and took delivery of goods earlier than usual this year. They have not only built-up inventories but have enhanced their inventory management practices. Some retailers have also chartered their own ships to counteract delays in transportation,” said Singhal.

They have also moved the unloading of their goods from the ports on the west coast to other ports in the U.S. that are less congested. These retailers have used their clout and deep pockets to get suppliers and logistics companies to prioritize their orders. Their far-flung supply chain networks can identify and work with several suppliers to find options to source items that are out of stock.

3. What are the financial ramifications to the U.S. and to the world for this supply chain issue?

The professors note that large companies have used their clout to deal with the current supply chain issues. Although their costs of procuring supplies have increased, they may be able to pass on some of the cost increase to customers. Some of these companies may see an increase in total sales and total profits in nominal terms although they may experience thinner profit margins. The stock market seems to have incorporated these factors in the valuations and the rising stock market suggests that large companies are expected to do fine financially. For example, the Dow Jones Index has jumped 18 percent this year, S&P 500 is up 25 percent, and Nasdaq has risen 24 percent.

The financial ramifications to smaller retailers and manufacturing firms may be quite negative. As Subramanian explained, these firms do not have the clout and financial resources to work around the supply issues. Often their sales during the holiday season are critically dependent on receiving a container or two of goods from overseas suppliers. Given the long and uncertain transportation and delivery times, and the high cost of transportation, many small firms may not be able to receive supplies in time for the holiday season and may be left holding unsold inventory or unfinished products. Overall, small firms may take a big hit from the current supply chain issues.

4. Are there any additional issues that consumers may face that they may not be aware of? How will the shortage of goods to retailers affect consumers shopping during the holidays? Is there anything individual consumers can do to help solve the problem?

Consumers can do certain things so that they are not disappointed, said the panel. They should start shopping earlier, expect to pay closer to full price on many products, and not wait for promotions or discounts to make their purchases. They will need to be flexible in their shopping habits and look for substitute products if their desired products are not available. Consumers may also want to prioritize their shopping decisions – for example, ensuring they have the gifts for young children who expect Santa to deliver irrespective of supply chain issues! Likewise, for older parents and relatives, for whom the holiday season is a very special time. For others, they may want to consider giving gift cards.

5. When do you think this issue will be resolved and how?

“Supply chains getting back to normal will be contingent upon the nature of the underlying supply chain issues. Shipping and retail executives indicate that they expect the West Coast port backlogs to clear in early 2022, when the Lunar New Year shuts many factories for a week in February, thus slowing output and shipments from Asia,” said Singhal. However, chip shortages may last until 2022 or even extend into 2023. Many chip manufacturers have announced plans to significantly increase their level of capital expenditure but bringing new capacity online can take several years.

This storm of collective issues has brought the importance of supply chain resilience to the forefront. Companies emerging from the pandemic are revisiting or will have to revisit their past approaches to managing supply chains.

Having flexibility and slack in supply chains has been a persistent strategy for several companies but this strategy will now need to be more holistic. For example, companies will need to re-think where to source their critical and irreplaceable components. Companies are already deliberating to not only near-shore suppliers of their critical components but also expand this supply base. This may also entail carrying more inventory of such components to meet demand variability and hedge against supply chain disruptions. Another development is manufacturers vertically integrating to design and produce critical components in-house.

Even before the pandemic, companies were investing in technology to digitize their supply chains. This long-term imperative will be prioritized even more as companies aspire for more transparency and traceability of products in their supply chains. Moreover, advanced automation in manufacturing plants and warehousing could ease some of the pain of labor shortages.

“Despite the current supply chain issues, we believe that supply chains will remain global and complex, but there will be renewed thinking in companies to recognize that Black Swan events such as the Covid-19 pandemic can create a multitude of interrelated and cascading supply chain issues that have serious financial implications. And companies will need to blend flexibility, adaptability, and efficiency to develop capabilities to mitigate impacts and remain resilient during such supply chain disruptions,” stated Hora.

News Contact

Lorrie Burroughs

Dec. 06, 2021

On October 28, 2021, the Georgia Tech Manufacturing Institute (GTMI) celebrated its 30th anniversary. The celebration event opened with a warm welcome from Ben Wang, executive director of GTMI, and concluded with GTMI’s annual distinguished lecture presented by Naveed Hussain, chief technology officer, vice president and general manager of Boeing research and technology.

Wang is the Eugene C. Gwaltney Jr. Chair in Manufacturing Systems, professor in the H. Milton Stewart School of Industrial and Systems Engineering, and professor in the School of Materials Science and Engineering at Georgia Tech.

Wang became the executive director of the Georgia Tech Manufacturing Research Center in January, 2012. Wang replaced Steven Danyluk, professor emeritus and Morris M. Bryan, Jr. Chair in Mechanical Engineering for Advanced Manufacturing Systems. Danyluk started his tenure as the director of the Georgia Tech Manufacturing Research Center in 1995.

At the 30th anniversary, Wang recalled the creation of Georgia Tech’s manufacturing center as a great example of a public-private partnership that started in 1991 when Georgia Tech, the Department of Defense, AT&T, Ford, Intel and Motorola helped to create a world-class research organization that started life known as the Georgia Tech Manufacturing Research Center who later became the Georgia Tech Manufacturing Institute.

At the event, Wang stressed the need for building a strong manufacturing base in the United States. “Technology-based innovation is the dominant driver of economic growth in the 21st century,” said Wang. “Our national security, high standard of living, and the rebuilding of the middle class all depend on a maintaining a strong manufacturing base.”

During his introductory remarks, Wang presented a short GTMI 30th anniversary video which can be viewed here.

When Wang became the executive director, his vision focused on what he called big “M” manufacturing. According to Wang, this included not only the creation of new materials, advanced composites, and biomaterials, but also included manufacturing processes as well as factory automation. It also incorporates supply chain management and enterprise transformation. Materials and manufacturing complement each other according to Wang. He emphasized manufacturing adds value and transforms raw materials into products we use daily.

The 30th anniversary event briefly highlighted the research being done in GTMI’s Advanced Manufacturing Pilot Facility (AMPF). Both Boeing and Delta Airlines have made significant investments to be part of AMPF. This innovative facility allows faculty, students, and industry partners to work with emerging technologies to research new ideas and solve industry problems, and the facility is designed to be flexible with the ability to evolve as new technologies become available.

An introduction to the AMPF facility can be viewed here.

Capping off the 30th celebration event was GTMI’s annual distinguished lecture which was delivered by Naveed Hussain, chief technology officer, vice president and general manager of Boeing research and technology. Hussain presented an overview of the Boeing company, emphasized the value of the Georgia Tech-Boeing partnership, and discussed the future of manufacturing at Boeing.

A full recording of GTMI’s 30th anniversary event, a more in-depth look at AMPF, and the distinguished lecture delivered by Naveed Hussain can be found here.

Speakers during the 30th anniversary AMPF presentations included: Christopher Saldana, Ring Family Professor and associate professor in the George W. Woodruff School of Mechanical Engineering; Andrew Dugenske, director of the Factory Information Systems Center and principal research engineer at GTMI; Shreyes Melkote, who holds the Morris M. Bryan, Jr. Professorship in Mechanical Engineering and is the associate director of GTMI; Chuck Zhang, Harold E. Smalley Professor in the H. Milton Stewart School of Industrial and Systems Engineering; and George White, interim vice president in the Office of Industry Collaboration at Georgia Tech.

The 30th anniversary event was organized by Paige Shee, strategic partners officer in GTMI.

Dec. 03, 2021

With holiday shopping deadlines looming, consumers cannot escape the impact of the global microelectronic chip shortage. From daily news reports about manufacturers unable to complete orders due to the lack of chips, to “out of stock” messages across websites on popular electronics items, one of the impacts of COVID was to lay bare the massive importance of the microelectronic chip in daily modern life, and how a single-location centered manufacturing nexus can upend the consumer market on a massive scale. The combination of these real-world impacts on supply chains, as well as the need to localize semiconductor and chip manufacturing gave Congress the impetus to pass the “Creating Helpful Incentives to Produce Semiconductors for America Act (CHIPS)”. CHIPS seeks to increase investments and incentives to support U.S. semiconductor manufacturing, research and development, and supply chain security.

The Georgia Institute of Technology was the first university to offer a comprehensive curriculum on microelectronics and microsystems design and packaging and, currently, numerous faculty at Georgia Tech are widely known for their work in semiconductor and microelectronics technologies. In December of 2021 Georgia Tech researchers will again showcase how their pushes the boundaries of microelectronics technologies at the IEEE International Electron Devices Meeting (IEDM).

The School of Electrical and Computer Engineering research teams of Assistant Professor Asif Khan, partnering with Dan Fielder Professor Muhannad Bakir, and Associate Professor Shimeng Yu, partnering with Professor Sung-Kyu Lim and Assistant Professor Shaolan Li, have dominated the 2021 IEDM presentation line-up with a total of 8 accepted papers. With topics ranging from ferroelectric materials for memory, new advances in ALD process, and in-memory computing and 3D reconfigurable architectures, the research presented by these teams is at the cutting-edge of advancing computing power and consumer electronics. In addition to the research presentations, Electrical and Computing Engineering Faculty & Director of the 3D Systems Packaging Research Center at GT will be presenting a short course session on devoted to “Heterogenous Integration Using Chiplets & Advanced Packaging”

Noting the timely nature of these research advancements, Arijit Raychowdhory; Professor and Steve W. Chaddick School Chair in Electrical and Computer Engineering noted, “IEDM is a premier conference in the area of semiconductor devices. Such a strong performance by GT ECE exemplifies the strength of our program, the ingenuity of our students and the innovation driven by our world-class faculty. Sincere congratulations to Professors Khan, Yu Bakir, Lim and Li for their pioneering research in semiconductor logic and memory technologies, that are critical for our nation and our industries.”

Asif Khan is an assistant professor in the School of Electrical and Computer Engineering at the Georgia Tech. He received his Ph.D. in electrical engineering and computer sciences from the University of California, Berkeley in 2015. His work led to the first experimental proof-of-concept demonstration of the negative capacitance effect in ferroelectric oxides. His group at Georgia Tech conceptualizes and fabricates electronic devices that leverage interesting physics and novel phenomena in emerging materials (such as ferroelectrics, antiferroelectrics and strongly correlated systems) to overcome the “fundamental” limits in computation and to address the most pressing challenges in electronics and the semiconductor industry.

Shimeng Yu is currently an associate professor in the School of Electrical and Computer Engineering at the Georgia Tech. He received the B.S. degree in microelectronics from Peking University in 2009, and the M.S. degree and Ph.D. degree in electrical engineering from Stanford University in 2011 and 2013, respectively. From 2013 to 2018, he was an assistant professor at Arizona State University. Prof. Yu’s research interests are the semiconductor devices and integrated circuits for energy-efficient computing systems. His research expertise is on the emerging non-volatile memories for applications such as deep learning accelerator, in-memory computing, 3D integration, and hardware security.

Muhannad S. Bakir is the Dan Fielder Professor in the School of Electrical and Computer Engineering at Georgia Tech. Dr. Bakir and his research group have received more than thirty paper and presentation awards including six from the IEEE Electronic Components and Technology Conference (ECTC), four from the IEEE International Interconnect Technology Conference (IITC), one from the IEEE Custom Integrated Circuits Conference (CICC), and two from the IEEE Transactions on Components Packaging and Manufacturing Technology (TCPMT). Muhannad S. Bakir received the B.E.E. degree from Auburn University, Auburn, AL, in 1999 and the M.S. and Ph.D. degrees in electrical and computer engineering from the Georgia Tech in 2000 and 2003, respectively. His research interests include, heterogeneous microsystem design and integration, including 2.5D and 3D ICs and packaging, electrical and photonic interconnects, and embedded cooling technologies.

Sung Kyu Lim received B.S. (1994), M.S. (1997), and Ph.D. (2000) degrees all from the Computer Science Department at UCLA. During 2000-2001, he was a post-doctoral scholar at UCLA, and a senior engineer at Aplus Design Technologies, Inc. Lim joined the School of Electrical and Computer Engineering at Georgia Institute of Technology an assistant professor. He is currently the director of the GTCAD (Georgia Tech Computer Aided Design) Laboratory and focuses on VLSI and 3D circuit architecture and packaging.

Shaolan Li received his B.Eng. degree with highest honor from the Hong Kong University of Science and Technology (HKUST) in 2012, and his Ph.D. from UT Austin in 2018, all in electrical engineering. Prior joining Georgia Tech as an assistant professor in 2019, he was a post-doctoral fellow in the Department of Electrical and Computer Engineering at UT Austin from 2018-2019. He also held intern positions in Broadcom Ltd. in Sunnyvale, California, and NXP in Tempe, Arizona during 2013-2014. His research interests are broadly in analog, mixed-signal, and RF integrated circuits. His expertise is in high-performance data converters, ultra-low-power low-cost sensor interface, and novel analog mixed-signal architectures for design automation.

The IEEE International Electron Devices Meeting (IEDM) is the world’s preeminent forum for reporting technological breakthroughs in the areas of semiconductor and electronic device technology, design, manufacturing, physics, and modeling. IEDM is the flagship conference for nanometer-scale CMOS transistor technology, advanced memory, displays, sensors, MEMS devices, novel quantum and nano-scale devices and phenomenology, optoelectronics, devices for power and energy harvesting, high-speed devices, as well as process technology and device modeling and simulation. Georgia Tech research teams have a strong track of record in IEDM publications in the recent years, including 8, 4, 9 and 7 papers presented in IEDM 2018, 2019, 2020 and 2021, respectively.

- Christa M. Ernst

News Contact

Christa M. Ernst - Interdisciplinary Research Communications Program Manager

Topics: Materials | Nanotechnology | Robotics

Georgia Institute of Technology| christa.ernst@research.gatech.edu

Nov. 30, 2021

By Frida Carrera

After almost a year since the completion of the 2021 InVenture Prize Competition, we caught up with Matt McMullen and Emma Bivings who competed as finalists on the SPOT Harness team, a harness that uses sensors and vibrators to help blind dogs navigate. Their experience in the competition exposed them to multiple experiences, environments, and demands necessary for startups for the first time. As a result, they were able to distinguish their areas of growth, gain valuable insights, and make potential changes in the direction of their product.

Today, Matt is currently a graduate student seeking a master’s in music technology and Emma is a full-time operations management trainee at McMaster-Carr. The team is still developing the SPOT Harness and has even grown its team to five members. Through funding and participating in Georgia Tech’s CREATE-X Startup Launch program, they have been able to launch their company Saving Grace Pet Solutions LLC. They plan to launch SPOT Harness under this company as well as develop other future products.

To future InVenture participants, Matt advises, “Don’t give up on your idea! The most important part of making it the distance is having a team with a passion for your product.”

The SPOT Harness team will be launching a kick-starter soon for preorders ahead of the official market launch of the SPOT Harness for blind dogs. They also advise anyone who has or knows someone who has a dog suffering from vision loss to visit their website to sign up for their newly refined prototype!

Visit their website here: www.savinggrace.tech

To learn more about the upcoming InVenture Prize Competition visit https://inventureprize.gatech.edu/ . Registration closes on Jan. 19.

Nov. 16, 2021

By Frida Carrera

Several months after the completion of the 2021 InVenture Prize Competition, we caught up with John Wooten to see what he’s been up to! In 2021’s competition, John’s innovation Block Transfer, a decentralized stock transfer agent protocol for global financial markets, placed as a finalist.

Today, John Wooten has been actively working to grow Block Transfer by securing final SEC approval, acquiring funding by US Bank, and submitting utility patents. He believes that by combining blockchain tech with traditional financial markets, we can fundamentally change the world. John describes his experience as a finalist in the competition as being invaluable and advises, “We didn't know we could partake given prior admission to CX. Biggest advice is to just TRY!”

You can learn more about Block Transfer here: https://www.blocktransfer.io/consult

To learn more about the upcoming InVenture Prize Competition visit https://inventureprize.gatech.edu/ . Registration closes on Jan. 19.