Jan. 15, 2025

From the physics of knitting to highlighting how batteries work, Georgia Tech photographers captured the impact and breadth of the Institute’s research enterprise. See our best shots and discover unseen gems in this collection.

Jan. 13, 2025

The new year provides a natural opportunity to refocus on professional growth. For busy supply chain professionals, development planning can often fall to the bottom of the priority list, especially amidst the daily challenges of managing operations and responding to disruption. Yet, this intentional focus on skill-building is more critical than ever.

As Managing Director of the Supply Chain and Logistics at Georgia Tech, I’ve seen firsthand how development planning can elevate individual careers, strengthen teams, and improve organizational resilience. However, the key to making it work lies in balancing the demands of day-to-day operations with actionable, targeted development efforts.

The Reality of Development Windows

The structure of the working calendar doesn’t make development planning easy. Between the end-of-year holiday season and summer vacation months, supply chain professionals face two primary windows for development:

- Spring (February through May): Coming off the end-of-year slowdown, spring provides the first extended opportunity to focus on growth.

- Fall (Mid-August through Mid-November): After summer, fall offers a second chance to refocus before the holiday rush begins.

For supply chain professionals, these windows represent critical periods to upskill and prepare for the evolving demands of the industry. The spring window is upon us, making now the perfect time to act with urgency and purpose.

The “Why” of Development Planning

In supply chain, the "why" behind development planning is straightforward: the industry is changing faster than ever. New technologies, shifting global trade patterns, and the increasing complexity of operations demand professionals who are both technically skilled and strategically agile.

The supply chain leaders of tomorrow must excel in areas like:

- Data and Analytics: Understanding data and leveraging it for decision-making is no longer optional.

- Automation and Technology: From warehouse robotics to AI-powered forecasting, supply chain professionals need to be tech-savvy to stay relevant.

- Resilience and Risk Management: Building robust supply chains capable of withstanding disruption is now a core competency.

The “What” of Development Planning: Key Focus Areas

Development can be broken into two primary areas:

1. Core Competencies (In-House):

- Communication: Clear, concise, and persuasive communication is critical for collaboration.

- Problem-Solving: Supply chains are inherently complex, and professionals must excel at diagnosing and resolving issues.

- Leadership and Teamwork: Even non-managers need strong leadership and collaboration skills to succeed in today’s cross-functional environments.

Here is a link to one of the best competency guides out there: FYI Resource Center

2. Technical and Operational Skills:

- Advanced Analytics and Visualization: Skills in tools like Power BI, Tableau, or Python are becoming industry standards.

- Supply Chain Systems and Automation: Understanding the functionality and implementation of WMS, TMS, and other critical systems is vital.

- Sustainability and Compliance: Professionals need to navigate increasingly complex sustainability requirements and global regulations.

Beyond these newer technical areas, there remain significant gaps in the application of many core supply chain processes—gaps that cannot be overlooked:

- Production and Inventory Planning: Effective planning processes are critical, yet many organizations struggle to optimize them to balance demand and capacity.

- Warehouse Operations and Optimization: Opportunities remain to improve material flow, labor efficiency, and space utilization in warehouse environments.

- Manufacturing Asset Reliability and Output: Ensuring consistent and reliable equipment performance is essential to maintaining throughput and meeting customer expectations.

- Tradeoff Analysis for Purchasing Decisions: Striking the right balance between low cost, resilience, and sustainability is an increasingly complex challenge, especially in the face of rising customer and consumer pressure for speed and service.

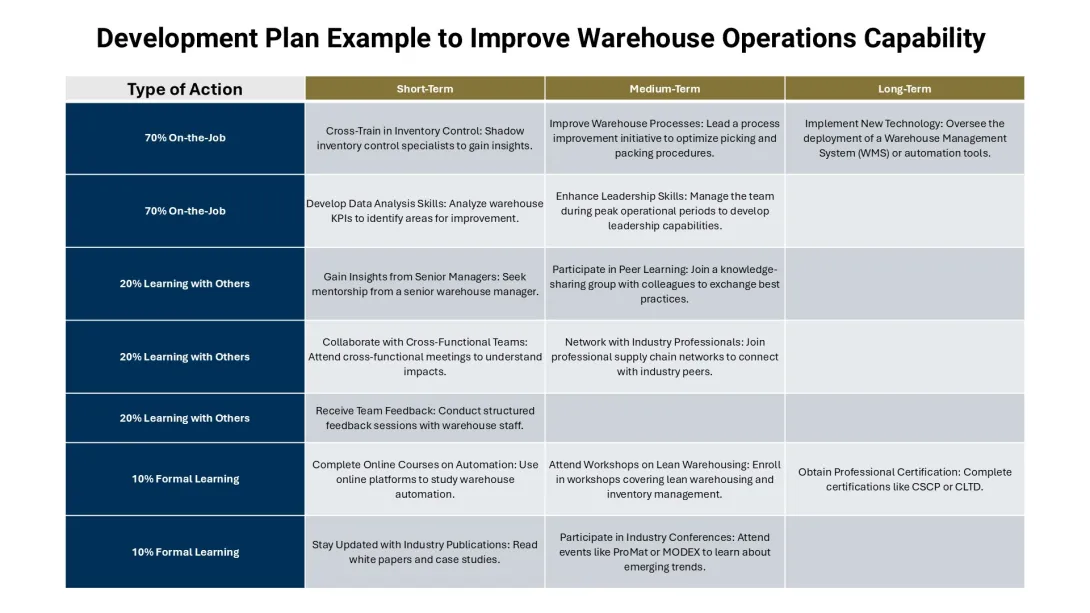

A Quick Action Plan Using the 70/20/10 Model

For supply chain professionals with limited time and access to leading practices, the 70/20/10 model offers a practical framework for development:

- 70% Experiential Learning: Apply learning directly in your work.

- 20% Social Learning: Learn from others in your network or organization.

- 10% Formal Learning: Invest in structured learning opportunities.

Please see attached figure 1 for Development Plan Example to improve Warehouse Operations Capability

Here is a link to a free Individual development GPT in Chat GPT: Individual Development Plan Builder

Call to Action: Take 30 Minutes to Plan Today

For busy professionals, the biggest hurdle to development planning is often finding the time. But a well-crafted development plan doesn’t have to take hours. Here's how you can get started in just 30 minutes:

- Reflect on Your Growth Needs (10 Minutes): Where do I need to grow most?

- Set Three Development Goals (10 Minutes): Identify experiential, social, and formal learning goals.

- Identify Next Steps (10 Minutes): Write down one immediate action for each goal.

- Schedule time with Manager to review proposed plan and schedule monthly check-ins

Development as a Competitive Advantage

The pace of change in supply chain operations is relentless, but professionals who make development a priority can turn that challenge into a competitive advantage. By leveraging the 70/20/10 model and focusing on intentional, actionable planning, you can position yourself—and your team—for success.

Don’t let this spring window pass without taking steps toward growth. Whether it’s mastering a new technology, improving core processes, or navigating tradeoff decisions, the time to act is now. If your growth plan includes professional education, consider how the Supply Chain and Logistics Institute and Georgia Tech Professional Education might benefit you!

News Contact

Jan. 13, 2025

Georgia Tech researchers have developed biosensors with advanced sleuthing skills and the technology may revolutionize cancer detection and monitoring.

The tiny detectives can identify key biological markers using logical reasoning inspired by the “AND” function in computers — like, when you need your username and password to log in. And unlike traditional biosensors comprised of genetic materials — cells, bits of DNA — these are made of manufactured molecules.

These new biosensors are more precise and simpler to manufacture, reducing the number of false positives and making them more practical for clinical use. And because the sensors are cell-free, there’s a reduced risk for immunogenic side effects.

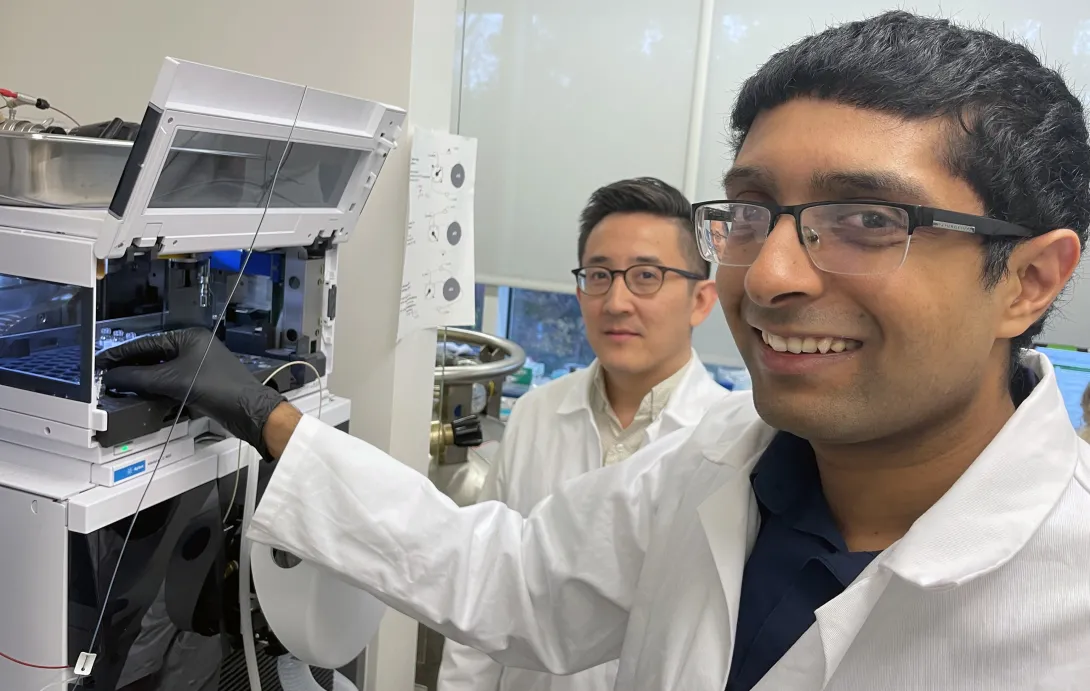

“We think the accuracy and simplicity of our biosensors will lead to accessible, personalized, and effective treatments, ultimately saving lives,” said Gabe Kwong, associate professor and Robert A. Milton Endowed Chair in the Wallace H. Coulter Department of Biomedical Engineering, who led the study, published this month in Nature Nanotechnology.

Breaking With Tradition

The researchers set out to address the limitations in current biosensors for cancer, like the ones designed for CAR-T cells to allow them to recognize tumor cells. These advanced biosensors are made of genetic material, and there is growing interest to reduce the potential for off-target toxicity by using Boolean “AND-gate” computer logic. That means they’re designed to release a signal only when two specific conditions are met.

“Traditionally, these biosensors involve genetic engineering using cell-based systems, which is a complex, time-consuming, and expensive process,” said Kwong.

So, his team developed biosensors made of iron oxide nanoparticles and special molecules called cyclic peptides. Synthesizing nanomaterials and peptides is a simpler, less costly process than genetic engineering, according to Kwong, “which means we can likely achieve large-scale, economical production of high-precision biosensors.”

Unlocking the AND-gate

Biosensors detect cancer signals and track treatment progress by turning biological signals into readable outputs for doctors. With AND-gate logic, two distinct inputs are required for an output.

Accordingly, the researchers engineered cyclic peptides — small amino acid chains — to respond only when they encounter two specific types of enzymes, proteases called granzyme B (secreted by the immune system) and matrix metalloproteinase (from cancer cells). The peptides generate a signal when both proteases are present and active.

Think of a high-security lock that needs two unique keys to open. In this scenario, the peptides are the lock, activating the sensor signal only when cancer is present and being confronted by the immune system.

“Our peptides allow for greater accuracy in detecting cancer activity,” said the study’s lead author, Anirudh Sivakumar, a postdoctoral researcher in Kwong’s Laboratory for Synthetic Immunity. “It’s very specific, which is important for knowing when immune cells are targeting and killing tumor cells.”

Super Specific

In animal studies, the biosensors successfully distinguished between tumors that responded to a common cancer treatment called immune checkpoint blockade therapy — ICBT, which enhances the immune system — from tumors that resisted treatment.

During these tests, the sensors also demonstrated their ability to avoid false signals from other, unrelated health issues, such as when the immune system confronted a flu infection in the lungs, away from the tumor.

“This level of specificity can be game changing,” Kwong said. “Imagine being able to identify which patients are responding to the therapy early in their treatment. That would save time and improve patient outcomes.”

The first step toward this simpler, precise form of cancer diagnostics began with an ambitious but humble ($50,000) seed grant from the Petit Institute for Bioengineering and Bioscience five years ago for a collaboration between Kwong’s lab and the lab of M.G. Finn, professor and chair in the School of Chemistry and Biochemistry.

It evolved into a multi-institutional project supported by grants from the National Science Foundation and National Institutes of Health that included researchers from the University of California-Riverside, as well as Georgia Tech faculty researchers Finn and Peng Qiu, associate professor in the Coulter Department.

“The progression of the research, from an initial seed grant all the way to animal studies, was very smooth,” Kwong said. “Ultimately, a collaborative, multidisciplinary effort turned our early vision into something that could have a great impact in healthcare.”

Citation: Anirudh Sivakumar, Hathaichanok Phuengkham, Hitha Rajesh, Quoc D. Mac, Leonard C. Rogers, Aaron D. Silva Trenkle, Swapnil Subhash Bawage, Robert Hincapie, Zhonghan Li, Sofia Vainikos, Inho Lee, Min Xue, Peng Qiu, M. G. Finn, Gabriel A. Kwong. “AND-gated protease-activated nanosensors for programmable detection of anti-tumour immunity.” Nature Nanotechnology (January 2025). https://doi.org/10.1038/s41565-024-01834-8

Funding: This research was supported in part by National Institutes of Health (NIH) grants 5U01CA265711, 5R01CA237210, 1DP2HD091793, and 5DP1CA280832.

News Contact

Jerry Grillo

Jan. 08, 2025

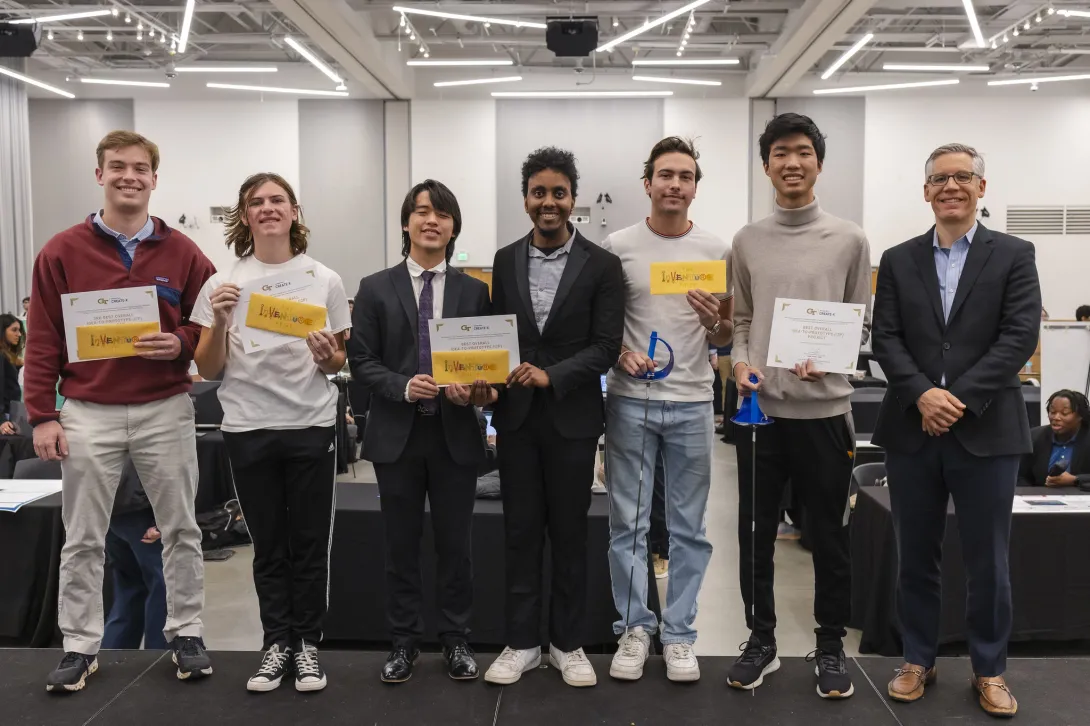

Two teams tied for Best Overall projects of the Fall 2024 I2P Showcase. Over two hours, 49 teams displayed prototypes that they developed over the semester to hundreds of attendees, while judges circulated the room. The showcase is the last event of their Idea-to-Prototype (I2P) course, where Georgia Tech students earn research credit (for undergraduate students only), receive up to $500 in reimbursement for physical material expenses, and build a working product with faculty mentorship. The course is held in the spring, summer, and fall. Graduate students can also take the course, and student can take it up two times.

As a part of the showcase, the winning team, or teams in this case, also receive a golden ticket into the CREATE-X summer startup accelerator, Startup Launch. This program provides founders with $5,000 in optional seed funding, $150,000 in in-kind services like accounting and legal services, mentorship, and entrepreneurial education, among other benefits. At the end of that experience, startup teams can present their products to investors and industry partners at Demo Day, which attracts over a thousand attendees each year.

Additionally, winners of the showcase advance directly to the semifinal round of the InVenture Prize, a faculty-led innovation competition for undergraduate students and recent BS graduates of Georgia Tech.

This semester, the first place teams were Allez Go and Soul. Team Allez Go’s founders, Adam Kulikowski and Jason Mo, created a real-time visualization system for fencing blades using infrared light and reflectors to accurately track positions during a bout. Team Soul, made up of Ashraf Mansour, Benjamin Wilson, and Michal Gregus, developed fitness-tracking soles and shoes, combining the functions of a smart scale, a workout tracker, and a diet tracker into a singular device.

Second place was awarded to Team Convexity Electronics, consisting of Calla Scotch, Levi Bloch, and Phi Cai. Convexity Electronics produces 3D-printed circuit boards that aim to be smaller, faster, and cheaper than lithography-based circuitry.

Team SuperStream, made up of solo-preneur John-Wright Stanly, took home third place. SuperStream adds video previews to URLs to increase engagement.

Read our Q&A with Team Allez Go and Soul below, and stay tuned for our interviews with the other winning teams!

Q&As

Team AllezGo

Adam Kulikowski, Sophomores, Computer Science

Jason Mo, Sophomores, Computer Science

Why did you pursue your startup?

Kulikowski: We're both fencers. I've been fencing for 10 years, and Jason's been fencing close to 10 as well. So, fencing as a sport is really hard to view for non-fencers, and so the idea that we wanted to do is use visualizations, animations, and replays in a similar way that other kinds of sport visualization companies did.

What was the I2P course like for you all?

Mo: So, this prototype actually started over the summer. I was in Startup Lab and just did a study abroad program. During that class, they mentioned that I2P is a great opportunity, and I had this prototype already in the works.

What surprised you about I2P?

Mo: I2P was very generous with funding; we never had any issues with using up our $500. It was just really helpful because our prototype was pretty heavy hardware.

What was your favorite part about I2P?

Mo: Our weekly meetings with Aaron Hillegass, our mentor, were always very, very insightful. I just shot him an email for I2P, hoping that we could work together on this. Sometimes we would talk about prototypes or updates. He had some really good insights, but our mentor also has a lot of industry experience and a lot of experience with his own startups. It was really fun to just ask him general questions and career advice. He was always very responsive, very supportive for us.

Kulikowski: In addition, I really liked seeing the iterations each week. I think the weekly updates kept us accountable to do at least one small thing every week. So, it was cool to see how the ideas slowly started to formulate each week, small steps and small progresses.

What was challenging about building your prototype over the semester?

Mo: There's a lot of technical challenges. One of the things we did this semester is we changed from a 30 frames per second (FPS) camera to a camera that shoots at 120 FPS. And with that, we could detect a lot more processing power. The camera that we're using is only limited to Windows. I've been using a very old laptop, and that's sort of been a bit problematic when we're trying to do very compute intensive tasks.

What would you say to students that are interested in entrepreneurship?

Kulikowski: There are a lot of people that came by our booth, and a lot of them were freshmen students. Every one of them we told, “If you have an idea, if you're really passionate about something, I2P is a fantastic opportunity.” This semester, with the hands-off approach, really felt like you could just work on this idea, and everything was there to support you working on it. That was fantastic because it's we could take full advantage of the time, the resources, and truly flesh out this idea. I really love the support we had and how we had the bonding with the other students.

Team Soul

Ashraf Mansour, Senior, Computer Science

Benjamin Wilson, Junior, Computer Science

Michal Gregus, Junior, Physics and Electrical Engineering

What’s the thought behind the name?

Mansour: We're kind of bringing life through our electronics, back into the shoe, and building a better fitness tracker and a more holistic picture of human health.

What was the showcase like for your team?

Wilson: It was a little nerve wracking. I have full faith in our ideas and concepts, but I feel personally like we still have a long way to go for our project. I’m still satisfied with where we are now, but we never really anticipated that we we're going to win anything.

Mansour: The showcase made me realize how much faster all this moves, even compared to my expectations. We came in with a very basic prototype that we wanted to improve on, but I think the potential was enough to sell the judges in this case. Now we have a big responsibility to deliver on that potential.

What was your favorite thing about I2P Showcase?

Mansour: It really reminds you how much of a tech hub Georgia Tech really is. Seeing how entrepreneurship boosts in real time, especially at the early stages, is something that’s really awe inspiring.

What was challenging about building your prototype over the semester?

Mansour: There are a lot of unique engineering challenges with the product that we’re building, some we anticipated and others we didn’t, but I think that speaks to the true soul of engineering. That adaptability and sense of problem solving is really important.

Wilson: I’m very grateful to have the other people that were involved in this project for brainstorming and making the design better.

What would you say to students that are interested in entrepreneurship?

Wilson: I definitely would encourage anyone that wants to pursue their own startup or has a new idea to just start. It’s far more efficient and far more rewarding to put your ideas out there and try. You’ll learn a lot more through that process of failing than you will contemplating.

A photo gallery from the Fall 2024 I2P Showcase can be viewed on the CREATE-X Flickr page.

CREATE-X is now accepting applications for the summer and fall semesters of the I2P course, and applications for their summer accelerator, Startup Launch. The deadline for I2P applications for Summer 2025 is May 12. The deadline for Startup Launch applications is March 19, 2025. For questions, please email create-x@groups.gatech.edu.

News Contact

Breanna Durham

Marketing Strategist

Jan. 08, 2025

Georgia Tech’s Executive Vice President for Research search committee has selected three finalists. Each candidate will visit campus and present a seminar sharing their broad vision for the Institute's research enterprise. The seminars are open to all faculty, students, and staff across the campus community. Interested individuals can attend in person or register to participate via Zoom (pre-registration is required).

Jan. 06, 2025

In the rapidly evolving world of manufacturing, embracing digital connectivity and artificial intelligence is crucial for optimizing operations, improving efficiency, and driving innovation. Internet of Things (IoT) is a key pillar of that process, enabling seamless communication and data exchange across the manufacturing process by connecting sensors, equipment, and applications through internet protocols.

The Georgia Tech Manufacturing Institute (GTMI) recently hosted the 10th annual Internet of Things for Manufacturing (IoTfM) Symposium, a flagship event that continues to set the standard for innovation and collaboration in the manufacturing sector. Held on Nov. 13, the symposium brought together industry leaders, researchers, and practitioners to explore the latest advancements and applications of IoT in manufacturing.

"The purpose is to bring the voice of manufacturers directly to the university community," explained Andrew Dugenske, a principal research engineer and director of the Factory Information Systems Center at GTMI. "It's about learning from industry to guide our research, education, and knowledge base, which is inherent to Georgia Tech."

Initiated over a decade ago, the IoTfM Symposium has grown into a premier event that highlights Georgia Tech's commitment to advancing manufacturing technologies.

"This symposium provides a unique platform to share and learn from cutting-edge advancements in IoT and now AI for manufacturing,” said Dago Mata, regional director of business development at Tata Consultancy Services (TCS) and one of the event’s speakers. “The opportunity to engage with industry leaders and showcase practical, real-world implementations was highly motivating."

This year’s symposium welcomed over 100 attendees from across the country. Speakers from TCS, Amazon Web Services, Southwire, and more shared insights on the latest advancements, use cases, current challenges, and future directions for IoT in manufacturing processes.

“My favorite aspect was the case studies presented by major manufacturers, highlighting successful IoT and AI implementations," said Mata, who has attended the symposium since 2018. "These provided actionable takeaways and inspiration for driving similar innovation in my projects — the blend of exclusive learning from real-world applications and the presence of diverse experts made it a truly practical and inspiring event."

A distinctive feature of the IoTfM Symposium is its commitment to providing a platform for industry partners to voice their perspectives on powerful manufacturing research, says Dugenske. "We ask our industry partners to tell us about their experiences, challenges, and future predictions. This way, we can guide our research with the real-world needs of the manufacturing sector to form stronger collaborations and better prepare our students."

This unique format not only enhances the relevance of the symposium but also fosters a collaborative environment where industry leaders can learn from each other and from Georgia Tech's academic community.

As GTMI looks to the future, the symposium will continue to evolve, incorporating new elements and expanding its reach. Dugenske envisions even greater integration with other GTMI initiatives and broader industry engagement.

"Our goal is to create an event that highlights our capabilities and builds deeper connections within the manufacturing community.”

News Contact

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Jan. 06, 2025

Samer Mabrouk and Omer Inan have been working on a wearable, battery-powered device that monitors joint health and gives personalized strengthening exercises. Inan and Mabrouk’s new company, Arthroba, created a device of the same name that uses electrical sensors to track swelling and tissue damage in the knee, ankle, and other critical joints.

Jan. 06, 2025

Effective January 1st, David Sherrill will serve as interim executive director of the Georgia Tech Institute for Data Engineering and Science (IDEaS). Sherrill is a Regents' Professor in the School of Chemistry and Biochemistry with a joint appointment in the College of Computing. Sherrill has served as associate director for IDEaS since its founding in 2016.

"David Sherrill's leadership role in IDEaS as associate director, together with his interdisciplinary background in chemistry and computer science, makes him the right person to support this transition as interim executive director," said Julia Kubanek, professor and vice president for interdisciplinary research at Georgia Tech.

Sherrill succeeds Srinivas Aluru who will be taking a new position as Senior Associate Dean in the College of Computing. Aluru, a Regents' Professor in the School of Computational Science and Engineering, co-founded IDEaS and served as its co-executive director (2016-2019) and then as executive director (2019-date), spanning eight and a half years. Under his leadership IDEaS grew to more than 200 affiliate faculty spanning all colleges, encompassing multiple state, federal, and industry funded centers. Notable among these is the South Big Data Hub, catalyzing the Southern data science community to collectively accelerate scientific discovery and innovation, spur economic development in the region, broaden participation and diversity in data science, and the CloudHub, a Microsoft funded center that provides research funding and cloud resources for innovative applications in Generative Artificial Intelligence. More recently, Aluru established the Center for Artificial Intelligence in Science and Engineering (ARTISAN), and expanded the Institute’s research staff to provide needed cyberinfrastructure, software resources, and expertise to support faculty projects with large data sets and AI-driven discovery. "I've had the pleasure of serving as Associate Director of IDEaS since it was founded by Srinivas Aluru and Dana Randall, and I'm excited to step into this interim role.” said Sherrill. “IDEaS has an important mission to serve the many faculty doing interdisciplinary research involving data science and high performance computing."

Sherrill’s research group focuses on the development of ab initio electronic structure theory and its application to problems of broad chemical interest, including the influence of non-covalent interactions in drug binding, biomolecular structure, organic crystals, and organocatalytic transition states. The group seeks to apply the most accurate quantum models possible for a given problem and specializes in generating high-quality datasets for testing new methods or machine-learning purposes.

Sherrill earned a B.S. in chemistry from MIT in 1992 and a Ph.D. in chemistry from the University of Georgia in 1996. From 1996-1999 Sherril was an NSF Postdoctoral Fellow, working under M. Head-Gordon, at the University of California, Berkeley.

Sherrill is a Fellow of the American Association for the Advancement of Science (AAAS), the American Chemical Society, and the American Physical Society, and he has been Associate Editor of the Journal of Chemical Physics since 2009. Sherrill has received a Camille and Henry Dreyfus New Faculty Award, the International Journal of Quantum Chemistry Young Investigator Award, an NSF CAREER Award, and Georgia Tech's W. Howard Ector Outstanding Teacher Award. In 2023, he received the Herty Medal from the Georgia Section of the American Chemical Society, and in 2024, he was elected to the International Academy of Quantum Molecular Science.

--Christa M. Ernst

News Contact

Christa M. Ernst [christa.ernst@research.gatech.edu],

Research Communications Program Manager,

Topic Expertise: Robotics | Data Sciences| Semiconductor Design & Fab

Dec. 18, 2024

As we go through our daily routines of work, chores, errands and leisure pursuits, most of us take our mobility for granted. Conversely, many people suffer from permanent or temporary mobility issues due to neurological disorders, stroke, injury, and age-related causes. Research in the field of robotic exoskeletons has shown significant potential to provide assistive support for patients with permanent mobility constraints, as well as an effective additional tool for rehabilitation and recovery after injury.

Though the field has made great progress in the hardware and devices for these assistive technologies, there are limitations in ease of use and in the ability to move from walking to running, from flat ground to slopes and stairs, and across different terrains. Recent developments to create exoskeleton controllers that are more responsive to the user’s environment via user-based variables such as gait and slope calculations provide rapid yet imprecise outputs. More recent inquiry into data-driven improvements such as vision-based labeling and classification are extremely promising additions in the goal to develop a true synchronous user and device interface. A major hindrance to this data-driven approach is the need for burdensome mounted cameras and on-board computing to allow for real-time in use adjustments to the environmental terrain encountered.

In order to address these barriers, Aaron Young, Associate Professor in the Woodruff School of Mechanical Engineering and Director of the Exoskeleton and Prosthetic Intelligent Controls (EPIC) Lab, and Dawit Lee, Postdoctoral Scholar at Stanford, have created an artificial intelligence (AI)-based universal exoskeleton controller that uses information from onboard mechanical sensors without the added weight and complexity of mounted vision based systems. The new work, published in Science Advances (Link to Be Added), presents a controller that holistically captures the major variations encountered during community walking in real-time. The team combined data from the Americans with Disabilities Act (ADA) building guidelines that characterize ambulatory terrains in slope level degrees with a gait phase estimator to achieve dynamic switching of assistance types between multiple terrains and slopes and delivery to the user with little to no delay.

In this work, we have created a new, open-source knee exoskeleton design that is intended to support community mobility. Knee assist devices have tremendous value in activities such as sit-to-stand, stairs, and ramps where we use our biological knees substantially to accomplish these tasks. The neat accomplishment in this work is that by leveraging AI, we avoid the need to classify these different modes discretely but rather have a single continuous variable (in this case rise over run of the surface) to enable continuous and unified control over common ambulatory tasks such as walking, stairs, and ramps. We demonstrate that on novel users of the device, we can track both the environment and the user’s gait state with very high accuracy out of the lab in community settings. It is an exciting time in the field as we see more studies, such as this one, showing promise in tackling real-world mobility challenges

The assistance approach using our intelligent controller, presented in this work, provides users with support at the right timing and with a magnitude that closely matches the varying biomechanical effort they produce as they move through the community. Our assistance approach was preferred for community navigation and was more effective in reducing the user’s energy consumption compared to conventional methods. We also open-sourced the design of the robotic knee exoskeleton hardware and the dataset used to train the models with this publication which allows other researchers to build upon our developments and further advance the field. This work demonstrates an exciting example of AI integration into a wearable robotic system, showcasing its successful outcomes and significant potential.

- Dawit Lee; Postdoctoral Scholar, Stanford

Using this combination of a universal slope estimator and a gait phase estimator, the team achieved results in the dynamic modulation of exoskeleton assistance that have never been achieved by previous approaches and moves the field closer to creating an adaptive and effective assistive technology that seamlessly integrates into the daily lives of individuals, promoting enhanced mobility and overall well-being. This work also has the potential to enable a mode-specific assistance approach tailored to the user’s specific biomechanical needs.

- Christa M. Ernst; Research Communications Program Manager

Original Publication

Dawit Lee, Sanghyub Lee, and Aaron J. Young, “AI-Driven Universal Lower-Limb Exoskeleton System for Community Ambulation,” Science Advances

Prior Related Work

D. Lee, I. Kang, D. D. Molinaro, A. Yu, A. J. Young, Real-time user-independent slope prediction using deep learning for modulation of robotic knee exoskeleton assistance. IEEE Robot. Autom. Lett. 6, 3995–4000 (2021).

Funding Provided by

NIH Director’s New Innovator Award DP2-HD111709

Dec. 12, 2024

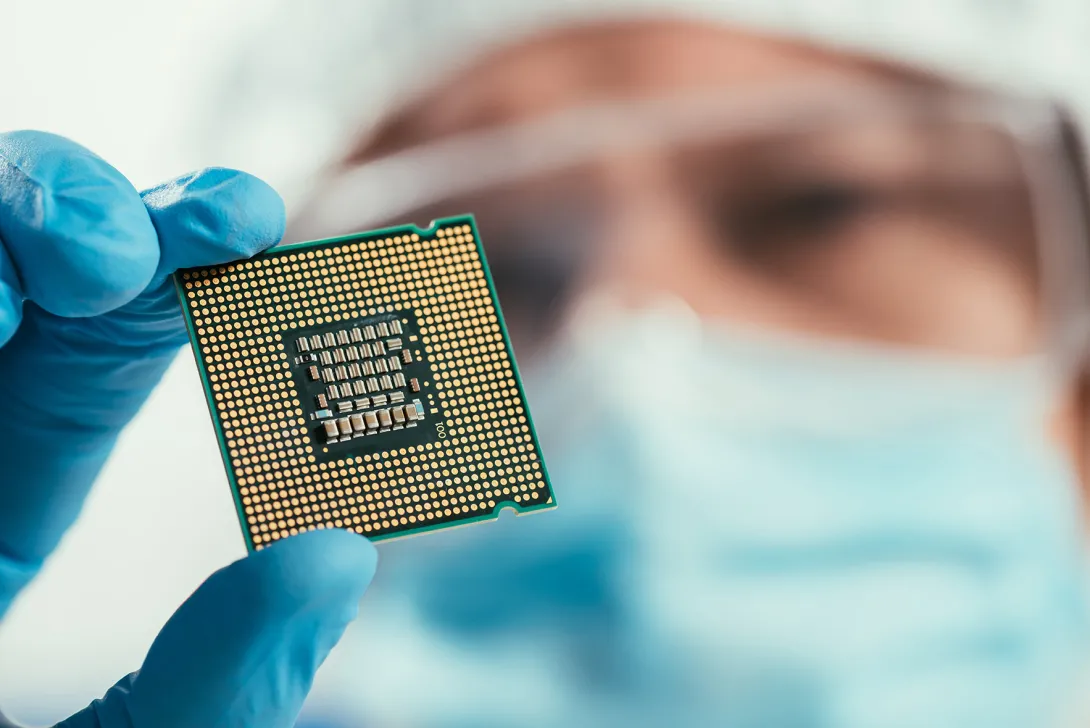

As part of the CHIPS National Advanced Packaging Manufacturing Program (NAPMP), three advanced packaging research projects will receive investments of up to $100 million each. This work will accelerate the development of cutting-edge substrate and materials technologies essential to the semiconductor industry.

NAPMP was developed to support a robust U.S. ecosystem for advanced packaging, which is key to every electronic system. NAPMP will enable leading-edge research and development, domestic manufacturing facilities, and robust training and workforce development programs in advanced packaging.

In partnership with Georgia Tech and the 3D Packaging Research Center (PRC), Absolics will receive $100 million to develop revolutionary glass core substrate panel manufacturing.

“This landmark investment in Absolics is also a transformational investment in Georgia Tech,” said Tim Lieuwen, interim executive vice president for Research. “It will redefine the possibilities of our longstanding partnership by expanding Georgia Tech’s expertise in electronic packaging, which is vital to the semiconductor supply chain. This federal funding uniquely positions us to merge cutting-edge research with industry, drive economic development in Georgia, and create a workforce ready to tackle tomorrow’s manufacturing demands.”

Georgia Tech has a long history of pioneering packaging research. Through a previous collaboration with the PRC, Absolics has already invested in the state of Georgia by building a glass core substrate panel manufacturing facility in Covington.

Georgia Tech’s Institute for Matter and Systems (IMS), home to the PRC, houses specialized core facilities with the capabilities for semiconductor advanced packaging research and development.

“Awards like this reinforce the importance of collaborative research between research disciplines and the private and public sector. Without the research and administrative support provided by IMS and the Georgia Tech Office of Research Development, projects like this would not be coming to Georgia Tech.” said Eric Vogel, IMS executive director.

Georgia Tech is a leader in advanced packaging research and has been working on glass substrate packaging research and development for years. Through this new Substrate and Materials Advanced Research and Technology (SMART) Packaging Program, Absolics aims to build a glass-core packaging ecosystem. In collaboration with Absolics, Georgia Tech will receive money for research and development for a glass-core substrate research center.

“We are delighted to partner with Absolics and the broader team on this new NAPMP program focused on glass-core packaging,” said Muhannad Bakir, Dan Fielder Professor in the School of Electrical and Computer Engineering and PRC director. “Georgia Tech’s role will span program leadership, research and development of novel glass-core packages, technology transition, and workforce development.” Bakir will serve as the associate director of SMART Packaging Program, overseeing research and workforce development activities while also leading several research tasks.

"This project will advance large-area glass panel processing with innovative contributions to materials and processing, modeling and simulation, metrology and characterization, and testing and reliability. We are pleased to partner with Absolics in advancing these important technology areas," said Regents' Professor Suresh K. Sitaraman of the George W. Woodruff School of Mechanical Engineering and the PRC. In addition to technical contributions, Sitaraman will direct the new SMART Packaging Program steering committee.

“The NAPMP Materials and Substrates R&D award for glass substrates marks the culmination of extensive efforts spearheaded by Georgia Tech’s Packaging Research Center,” noted George White, senior director of strategic partnerships and the theme leader for education and workforce development in the SMART Packaging Program. “This recognition highlights the state of Georgia’s leadership in advanced substrate technology and paves the way for developing the next generation of talent in glass-based packaging.”

The program will support education and workforce development efforts by bringing training, internships, and certificate opportunities to technical colleges, the HBCU CHIPS Network, and veterans' programs.

News Contact

Amelia Neumeister | Research Communications Program Manager