Dec. 11, 2024

Gold and white pompoms fluttered while Buzz, the official mascot of the Georgia Institute of Technology, danced to marching band music. But the celebration wasn’t before a football or basketball game — instead, the cheers marked the official launch of Georgia AIM Week, a series of events and a new mobile lab designed to bring technology to all parts of Georgia

Organized by Georgia Artificial Intelligence in Manufacturing (Georgia AIM), Georgia AIM Week kicked off September 30 with a celebration on the Georgia Institute of Technology campus and culminated with another celebration on Friday at the University of Georgia in Athens and aligned with National Manufacturing Day.

In between, the Georgia AIM Mobile Studio made stops at schools and community organizations to showcase a range of technology rooted in AI and smart technology.

“Georgia AIM Week was a statewide opportunity for us to celebrate Manufacturing Day and to launch our Georgia AIM Mobile Studio,” said Donna Ennis, associate vice president, community-based engagement, for Georgia Tech’s Enterprise Innovation Institute and Georgia AIM co-director. “Georgia AIM projects planned events in cities around the state, starting here in Atlanta. Then we headed to Warner Robins, Southwest Georgia, and Athens. We’re excited about the opportunity to bring this technology to our communities and increase access and ideas related to smart technology.”

Georgia AIM is a collaboration across the state to provide the tools and knowledge to empower all communities, particularly those that have been underserved and overlooked in manufacturing. This includes rural communities, women, people of color, and veterans. Georgia AIM projects are located across the state and work within communities to create a diverse AI manufacturing workforce. The federally funded program is a collaborative project administered through Georgia Tech’s Enterprise Innovation Institute and the Georgia Tech Manufacturing Institute.

A cornerstone of Georgia AIM Week was the debut of the Georgia AIM Mobile Studio, a 53-foot custom trailer outfitted with technology that can be used in manufacturing — but also by anyone with an interest in learning about AI and smart technology. Visitors to the mobile studio can experience virtual reality, 3-D printing, drones, robots, sensors, computer vision, and circuits essential to running this new tech.

There’s even a dog — albeit a robotic one — named Nova.

The studio was designed to introduce students to the possibilities of careers in manufacturing and show small businesses some of the cost-effective ways they can incorporate 21st century technology into their manufacturing operations.

“We were awarded about $7.5 million to build this wonderful studio here,” said Kenya Asbill, who works at the Russell Innovation Center for Entrepreneurs (RICE) as the Economic Development Administration project manager for Georgia AIM. “We will be traveling around the state of Georgia to introduce artificial intelligence in manufacturing to our targeted communities, including underserved rural and urban residents.”

Some technology on the Georgia AIM Mobile Studio was designed in consultation with project partners Kitt Labs and Technologists of Color. An additional suite of “technology vignettes” were developed by students at the University of Georgia College of Engineering. RICE and UGA served as project leads for the mobile studio development, and RICE will oversee its deployment across the state in the coming months.

To request a mobile studio visit, please visit the Georgia AIM website.

During Monday’s kickoff, the Georgia Tech cheerleaders and Buzz fired up the crowd before an event that featured remarks by Acting Assistant Secretary of the U.S. EDA Christina Killingsworth; Jay Bailey, president and CEO of RICE; Beshoy Morkos, associate professor of mechanical engineering at the University of Georgia; Aaron Stebner, co-director of Georgia AIM; David Bridges, vice president of Georgia Tech’s Enterprise Innovation Institute; and lightning presentations by Georgia AIM project leads from around the state.

Following the presentations, mobile studio tours were led by Jon Exume, president and executive director, and Mark Lawson, director of technology, for Technologists of Color. The organization works to create a cohesive and thriving community of African Americans in tech.

“I’m particularly excited to witness the launch of the Georgia AIM Mobile Studio. It really will help demystify AI and bring its promise to underserved rural areas across the state,” Killingsworth said. “AI is the defining technology of our generation. It’s transforming the global economy, and it will continue to have tremendous impact on the global workforce. And while AI has the potential to democratize access to information, enhance efficiency, and allow humans to focus on the more complex, creative, and meaningful aspects of work, it also has the power to exacerbate economic disparity. As such, we must work together to embrace the promise of AI while mitigating its risks.”

Other events during Georgia AIM week included the Middle Georgia Innovation Corridor Manufacturing Expo in Warner Robins, West Georgia Manufacturing Day – Student Career Expo in LaGrange, and a visit to Colquitt County High School in Moultrie. The week wrapped on Friday, Oct. 4, at the University of Georgia in Athens with a National Manufacturing Day celebration.

“We’re focused on growing our manufacturing economy,” Ennis said. “We’re also focused on the development and deployment of innovation and talent in the manufacturing industry as it relates to AI and other technologies. Manufacturing is cool. It is a changing industry. We want our students and younger people to understand that this is a career.”

News Contact

Dec. 10, 2024

Ebenezer Fanijo and David Citrin lead the “Waste Materials Processing” research initiative for the Institute for Matter and Systems at Georgia Tech. Their research in this role focuses on creating innovative construction materials from waste streams to reduce carbon emissions in construction. Fanijo is a professor in the School of Building Construction and Citrin is a professor in the School of Electrical and Computer Engineering.

In this brief Q&A, Fanijo and Citrin discuss their research focus, how it relates to Matter and System’s core research focuses, and the national impact of this initiative.

What is your field of expertise and at what point in your life did you first become interested in this area?

Fanijo - My research focuses on sustainable buildings and civil infrastructure, particularly decarbonizing through low-carbon materials and alternative energy sources. I also specialize in in-situ nanoscale quantification of cementitious materials and metals using advanced characterization techniques. My interest in this field grew during my graduate studies and after attending the First International Conference on Sustainable Production and Use of Cement and Concrete.

Citrin - Several years ago, I supervised a masters project using an automated imaging system to identify construction materials. My core interests are in terahertz imaging and applications of machine learning, so the IMS project brought these two together.

What questions or challenges sparked your current research?

Fanijo - Buildings account for 39% of global energy-related CO2 emissions and 35% of energy consumption, primarily due to manufacturing, materials, and transportation. Therefore, advanced research into innovative construction materials derived from waste streams is essential to reduce carbon emissions throughout the building lifecycle.

Citrin - The societal problems of how to reuse construction waste is urgent. Identifying those materials that can be reused and separating them from those that are tainted presents fascinating technical problems and is a tremendous challenge.

Matter and systems refer to the transformational technological and societal systems that arise from the convergence of innovative materials, devices, and processes. Why is your initiative important to the development of the IMS research strategy?

While “construction materials” evokes low tech, in fact, there have been tremendous advances in the materials as well as how they are used. Connecting such advances with the environmental challenges we face with new technological opportunities to mitigate these problems fits squarely in the remit of the IMS research strategy.

What are the broader global and social benefits of the research you and your team conduct?

One of the greatest components by volume filling landfills is construction waste. This waste is typically unsorted by material and tainting by hazardous waste is also common, making recycling prohibitively difficult. By sorting the materials in real time and identifying tainted versus untainted waste, we aim to reduce the quantity of such waste landfilled and to reduce the quantities of new materials made by reusing the old.

What are your plans for engaging a wider Georgia Tech faculty pool with the Institute for Matter and Systems research?

The leads on this project are experts in construction waste and in terahertz imaging. But what we envisage for this program will ultimately involve image processing and machine learning, materials science and chemical engineering, as well as actively recycling these materials for reuse.

News Contact

Amelia Neumeister | Research Communications Program Manager

Dec. 09, 2024

The National Academy of Inventors (NAI) is adding two more Georgia Tech researchers to its roster of innovators: Larry Heck and Younan Xia.

Heck is an artificial intelligence and speech recognition pacesetter who helped create virtual assistants for Microsoft, Samsung, Google, and Amazon. Xia is a nanomaterials pioneer whose inventions include silver nanowires commercialized for use in touchscreen displays, flexible electronics, and photovoltaics.

Election to NAI is the highest professional distinction specifically awarded to inventors. Founded in 2012, the NAI Fellows program has recognized 22 Georgia Tech innovators — 12 in just the last five years. Xia and Heck join a 2025 class of 170 new fellows representing university, government, and nonprofit organizations worldwide.

News Contact

Joshua Stewart

College of Engineering

Dec. 09, 2024

CREATE-X is pleased to announce the next cohort of faculty members selected for the Jim Pope Fellowship for the upcoming academic year. The program provides faculty fellows with funds and education to serve as entrepreneurial instructors, mentors, and advisors to students participating in CREATE-X, Georgia Tech's entrepreneurial learning incubator.

Each fellow receives $15,000 in discretionary funds, which can be used to seek a partial reprieve from teaching for one semester. Fellows also receive mentorship, education on evidence-based entrepreneurship through courses, and opportunities to work with students launching startups.

The new Jim Pope Fellows are:

- Adam McCallum is a translational research advocate for the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University. His work focuses on how metals function in our bodies, utilizing synthetic ligands as chemical tools to explore the biochemistry of metals in biological systems. He collaborates with faculty members, students, and researchers in BME to promote the translation and commercialization of biomedical technologies developed at Georgia Tech and Emory while also encouraging entrepreneurship. Adam earned his Ph.D. in chemistry, with a focus on organic chemistry, from Georgia Tech. He then pursued a postdoctoral fellowship at Emory in Dennis Liotta's lab, where he conducted drug design and discovery research to develop novel therapeutics for various clinical indications.

- Yue Chen is an assistant professor in the Walter H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University. He also is a member of the Discovery and Developmental Therapeutics Research Program at Winship Cancer Institute. His work addresses building the scientific and technical foundations for various robotic systems and applying them in the medical field. His lab is especially interested in designing, building, modeling, and controlling robots. Among these robots are a commercial robot arm and many custom-made robots, like tube robots, tendon-driven robots, catheters, and soft robots. He received a Ph.D. in mechanical engineering from Vanderbilt University, an M.S. in mechanical engineering from Hong Kong Polytechnic University, and a B.S. in vehicle engineering from Hunan University. This year, he won the National Science Foundation CAREER Award and is developing a continuum robotic system that can efficiently perform procedures like radio frequency ablation while a patient is inside a magnetic resonance imaging scanner.

- Mioy Huynh is an academic professional in the School of Chemistry and Biochemistry who earned his Ph.D. in physical and computational chemistry as an NSF Graduate Research Fellow at the University of Illinois at Urbana-Champaign, where he studied proton-coupled electron transfer reactions. He has taught at Yale University, UCLA, and the Claremont Colleges. Huynh began his professional career in chemistry education as a lecturer and summer instructor at UIUC. After postdoctoral research at Boston University and the University of Wisconsin, he held lecturer positions in general and physical chemistry at Yale, UCLA, and the Claremont Colleges.

- Cici McNamara is an assistant professor in the School of Economics. McNamara studied economics and English for her undergraduate studies, and then graduated from the University of Wisconsin-Madison with a Ph.D. in economics. McNamara’s research interests are in empirical industrial organization. She studies how policies influence the demand and supply of health care and what are the impacts of resulting changes on the market and patient outcomes. She is also a health economist, and her recent work has examined the effects of financial incentives and competition on healthcare market outcomes. Her research on health care consolidation has been integrated into the Vertically Integrated Project, and she was named an AcademyHealth Rising Star in Health Economics in 2023. Among her awards and fellowships, McNamara has also presented her work at numerous conferences and seminars, including the Allied Social Science Associations Annual Meeting, the American Health Economics Conference, and the International Industrial Organization Conference.

- Morvarid Rahmani is an associate professor of operations management in the Scheller College of Business. She received her Ph.D. from the UCLA Anderson School of Management. She also received three master degrees, in industrial engineering, electrical engineering, and economics. Her research focuses on innovation and social sustainability, providing managers with insights to enhance work processes, drive successful innovation, and address social issues. Rahmani recently received the Best Paper Award from the journal Manufacturing & Service Operations Management (M&SOM) for her research on maximizing the social impact of nonprofit organizations on distressed individuals. She has also received the Brady Family Award for Faculty Teaching Excellence at the Scheller College of Business, the CTL/BP Faculty Teaching Excellence Award at Georgia Tech, and CIOS Student Recognition of Excellence in Teaching Award, among other awards. Rahmani is the founding chair of the Technology Innovation and Entrepreneurship (TIE) Special Interest Group (SIG) of the Manufacturing and Service Operations Management (MSOM). She has also served as the Chair of the Technology, Innovation Management and Entrepreneurship (TIMES) Section of INFORMS and as a vice president of the Product Innovation and Technology Management (PITM) College of Production and Operations Management Society (POMS).

- Jud Ready: Ready is a principal research engineer and the deputy director of Innovation Initiatives for the Georgia Tech Institute for Materials. He is also the associate director of External Engagements for the Georgia Tech Institute for Matter and Systems and has been an adjunct professor in the School of Materials Science and Engineering at Georgia Tech for over 20 years. Ready has over 2,200 citations to his three dozen refereed publications and has been invited to over two dozen international conferences. He has 15 patents awarded in the United States, with many others pending. He has also served as an expert witness in criminal and civil cases, provided testimony to the Georgia State House Science and Technology Committee, and served on boards and committees. He has served as PI or co-PI for grants totaling over $20 million from various organizations, including the Army, Navy, Air Force, DARPA, NASA, NSF, NIST, industry, charitable foundations, private citizens, and the state governments of Georgia and Florida. His current research, with an emphasis on aerospace applications, focuses on energy capture, storage, and delivery enabled by nanomaterial design. His research has been included in missions to the International Space Station, low Earth orbit, and heliocentric orbit.

- Fan Zhang is an assistant professor in nuclear and radiological engineering and the George W. Woodruff School of Mechanical Engineering. She received her Ph.D. in nuclear engineering and an M.S. in statistics from the University of Tennessee. Her research focuses on the cybersecurity of nuclear facilities, online monitoring and fault detection using data analytics methods, instrumentation and control, and nuclear systems modeling and simulation. She has developed multiple test beds using both simulators and physical components to investigate various aspects of cybersecurity and process health management. Her research also includes AI/ML, operation optimization, digital twins, predictive maintenance, autonomous controls, robotics, and XR. Zhang is a Georgia Tech College of Engineering Cybersecurity Fellow and has received several prestigious awards. She is the recipient of the 2021 Ted Quinn Early Career Award from the American Nuclear Society for her contributions to instrumentation and control and cybersecurity. In 2022, she was awarded the inaugural Distinguished Early Career Award from the U.S. DOE Office of Nuclear Energy. Additionally, Zhang was recognized as one of UT's 2023 Volunteer 40 Under 40 and is a Grainger Foundation Frontiers of Engineering Alumni.

The Jim Pope Fellowship spans three consecutive semesters. During the fall semester, faculty fellows learn principles of evidence-based entrepreneurship by attending a workshop and shadow teaching one of the CREATE-X courses, Startup Lab, which teaches undergraduates how to examine startup ideas through customer discovery, testing hypotheses, and constructing minimum viable products.

In the spring semester, fellows scope an entrepreneurial project to implement within their home unit, such as creating entrepreneurial assignments within an established course, hosting workshops, or developing a new course that integrates entrepreneurship.

Once the summer semester starts, the cohort works with student startups through CREATE-X Startup Launch, serving as mentors or coaches. After completing the program, fellows spend the next two years leading CREATE-X programs.

Since its creation, the Jim Pope Fellowship has supported 25 fellows, represented 11 Georgia Tech departments, secured $1 million in funding and facilities for makerspaces, and introduced 2,500 students to entrepreneurship.

Faculty members interested in getting involved with CREATE-X can participate as teachers or mentors in various programs such as Startup Lab, CREATE-X Capstone, Idea-to-Prototype, and Startup Launch. Faculty can also apply for the next cohort of the Jim Pope Fellowship when it opens in the spring. For additional information or inquiries, contact the director of CREATE-X, Rahul Saxena, at rahulsaxena@gatech.edu.

News Contact

Breanna Durham

Marketing Strategist

Dec. 05, 2024

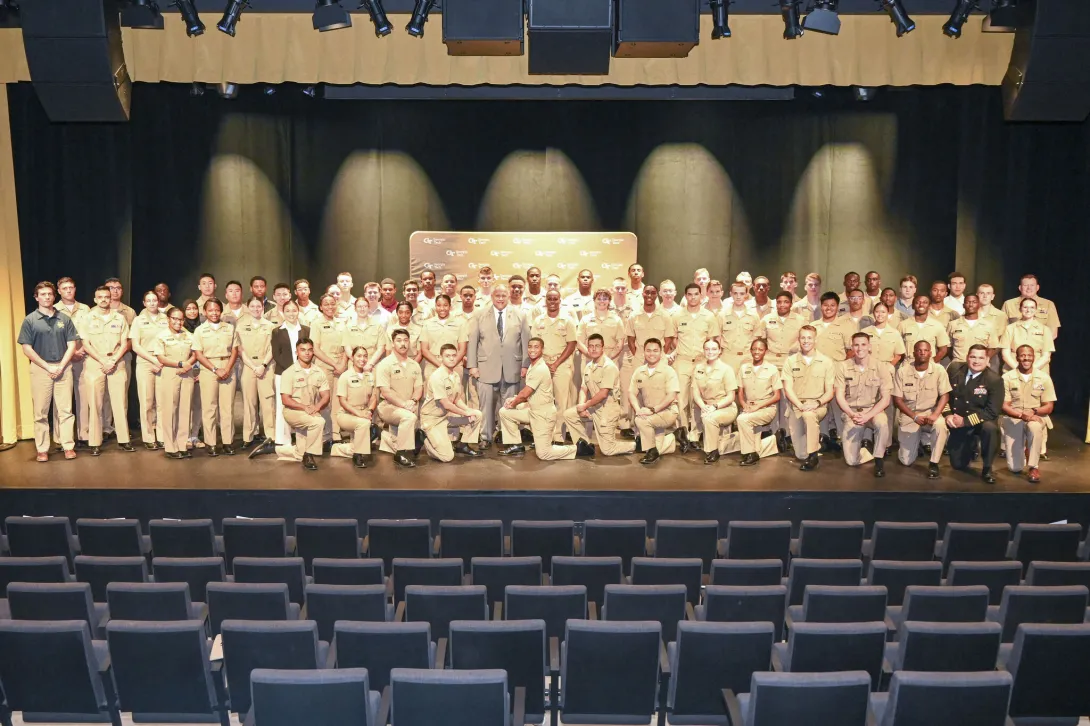

The Georgia Tech Research Institute (GTRI) proudly hosted U.S. Secretary of the Navy Carlos Del Toro during his recent campus visit. Del Toro's visit underscored the critical role of innovation and technology in national security and highlighted Georgia Tech's significant contributions to this effort.

“Our Navy-Marine Corps Team remains at the center of global and national security — maintaining freedom of the seas, international security, and global stability,” he explained in his remarks at the John Lewis Student Center. “To win the fight of the future, we must embrace and implement emerging technologies.”

The Secretary provided an update on science and technology research to the Atlanta Region Naval Reserve Officer Training Corps unit, comprised of midshipmen from Georgia Tech, Georgia State University, Kennesaw State University, Morehouse College, Spelman College, and Clark Atlanta University. Del Toro has worked to establish a new Naval Science and Technology Strategy to address current and future challenges faced by the Navy and Marine Corps. The strategy serves as a global call to service and innovation for stakeholders in academia, industry, and government.

“The Georgia Tech Research Institute has answered this call,” he said.

A key pillar of the new strategy, says Del Toro, was the establishment of the Department of the Navy’s Science and Technology Board in 2023, “with the intent that the board provide independent advice and counsel to the department on matters and policies relating to scientific, technical, manufacturing, acquisition, logistics, medicine, and business management functions.”

The board, which includes Georgia Tech Manufacturing Institute (GTMI) Executive Director Thomas Kurfess, has conducted six studies in its inaugural year to identify new technologies for rapid adoption and provide near-term, practical recommendations for quick implementation by the Navy.

“I recently led the team for developing a strategy for integrating additive manufacturing into the Navy’s overall shipbuilding and repair strategy,” says Kurfess. “We just had final approval of our recommendations — we are making a significant impact on the Navy with respect to additive manufacturing.”

Del Toro's visit to Georgia Tech reaffirms the Institute's role as a leader in research and innovation, particularly in areas critical to national security. The collaboration between Georgia Tech and the Department of the Navy continues to drive advancements that ensure the safety and effectiveness of the nation's naval forces.

“Innovation is at the heart of our efforts at Georgia Tech and GTMI,” says Kurfess. “It is an honor to put that effort toward ensuring our country’s safety and national security in partnership with the U.S. Navy.”

“As our department continues to reimagine and refocus our innovation efforts,” said Del Toro, “I encourage all of you — our nation’s scientists, engineers, researchers, and inventors — to join us.”

News Contact

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Dec. 05, 2024

As automation and AI continue to transform the manufacturing industry, the need for seamless integration across all production stages has reached an all-time high. By digitally designing products, controlling the machinery that builds them, and collecting precise data at each step, digital integration streamlines the entire manufacturing process — cutting down on waste materials, cost, and production time.

Recently, the Georgia Tech Manufacturing Institute (GTMI) teamed up with OPEN MIND Technologies to host an immersive, weeklong training session on hyperMILL, an advanced manufacturing software enabling this digital integration.

OPEN MIND, the developer of hyperMILL, has been a longtime supporter of research operations in Georgia Tech’s Advanced Manufacturing Pilot Facility (AMPF). “Our adoption of their software solutions has allowed us to explore the full potential of machines and to make sure we keep forging new paths,” said Steven Ferguson, a principal research scientist at GTMI.

Software like hyperMILL helps plan the most efficient and accurate way to cut, shape, or 3D print materials on different machines, making the process faster and easier. Hosted at the AMPF, the immersive training offered 10 staff members and students a hands-on platform to use the software while practicing machining and additive manufacturing techniques.

“The number of new features and tricks that the software has every year makes it advantageous to stay current and get a refresher course,” said Alan Burl, a Ph.D. student in the George W. Woodruff School of Mechanical Engineering who attended the training session. “More advanced users can learn new tips and tricks while simultaneously exposing new users to the power of a fully featured, computer-aided manufacturing software.”

OPEN MIND Technologies has partnered with Georgia Tech for over five years to support digital manufacturing research, offering biannual training in their latest software to faculty and students.

“Meeting the new graduate students each fall is something that I look forward to,” said Brad Rooks, an application engineer at OPEN MIND and one of the co-leaders of the training session. “This particular group posed questions that were intuitive and challenging to me as a trainer — their inquisitive nature drove me to look at our software from fresh perspectives.”

The company is also a member of GTMI’s Manufacturing 4.0 Consortium, a membership-based group that unites industry, academia, and government to develop and implement advanced manufacturing technologies and train the workforce for the market.

“The strong reputation of GTMI in the manufacturing industry, and more importantly, the reputation of the students, faculty, and researchers who support research within our facilities, enables us to forge strategic partnerships with companies like OPEN MIND,” says Ferguson, who also serves as executive director of the consortium. “These relationships are what makes working with and within GTMI so special.”

News Contact

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Dec. 04, 2024

Georgia Tech researchers have created a dataset that trains computer models to understand nuances in human speech during financial earnings calls. The dataset provides a new resource to study how public correspondence affects businesses and markets.

SubjECTive-QA is the first human-curated dataset on question-answer pairs from earnings call transcripts (ECTs). The dataset teaches models to identify subjective features in ECTs, like clarity and cautiousness.

The dataset lays the foundation for a new approach to identifying disinformation and misinformation caused by nuances in speech. While ECT responses can be technically true, unclear or irrelevant information can misinform stakeholders and affect their decision-making.

Tests on White House press briefings showed that the dataset applies to other sectors with frequent question-and-answer encounters, notably politics, journalism, and sports. This increases the odds of effectively informing audiences and improving transparency across public spheres.

The intersecting work between natural language processing and finance earned the paper acceptance to NeurIPS 2024, the 38th Annual Conference on Neural Information Processing Systems. NeurIPS is one of the world’s most prestigious conferences on artificial intelligence (AI) and machine learning (ML) research.

"SubjECTive-QA has the potential to revolutionize nowcasting predictions with enhanced clarity and relevance,” said Agam Shah, the project’s lead researcher.

“Its nuanced analysis of qualities in executive responses, like optimism and cautiousness, deepens our understanding of economic forecasts and financial transparency."

[MICROSITE: Georgia Tech at NeurIPS 2024]

SubjECTive-QA offers a new means to evaluate financial discourse by characterizing language's subjective and multifaceted nature. This improves on traditional datasets that quantify sentiment or verify claims from financial statements.

The dataset consists of 2,747 Q&A pairs taken from 120 ECTs from companies listed on the New York Stock Exchange from 2007 to 2021. The Georgia Tech researchers annotated each response by hand based on six features for a total of 49,446 annotations.

The group evaluated answers on:

- Relevance: the speaker answered the question with appropriate details.

- Clarity: the speaker was transparent in the answer and the message conveyed.

- Optimism: the speaker answered with a positive outlook regarding future outcomes.

- Specificity: the speaker included sufficient and technical details in their answer.

- Cautiousness: the speaker answered using a conservative, risk-averse approach.

- Assertiveness: the speaker answered with certainty about the company’s events and outcomes.

The Georgia Tech group validated their dataset by training eight computer models to detect and score these six features. Test models comprised of three BERT-based pre-trained language models (PLMs), and five popular large language models (LLMs) including Llama and ChatGPT.

All eight models scored the highest on the relevance and clarity features. This is attributed to domain-specific pretraining that enables the models to identify pertinent and understandable material.

The PLMs achieved higher scores on the clear, optimistic, specific, and cautious categories. The LLMs scored higher in assertiveness and relevance.

In another experiment to test transferability, a PLM trained with SubjECTive-QA evaluated 65 Q&A pairs from White House press briefings and gaggles. Scores across all six features indicated models trained on the dataset could succeed in other fields outside of finance.

"Building on these promising results, the next step for SubjECTive-QA is to enhance customer service technologies, like chatbots,” said Shah, a Ph.D. candidate studying machine learning.

“We want to make these platforms more responsive and accurate by integrating our analysis techniques from SubjECTive-QA."

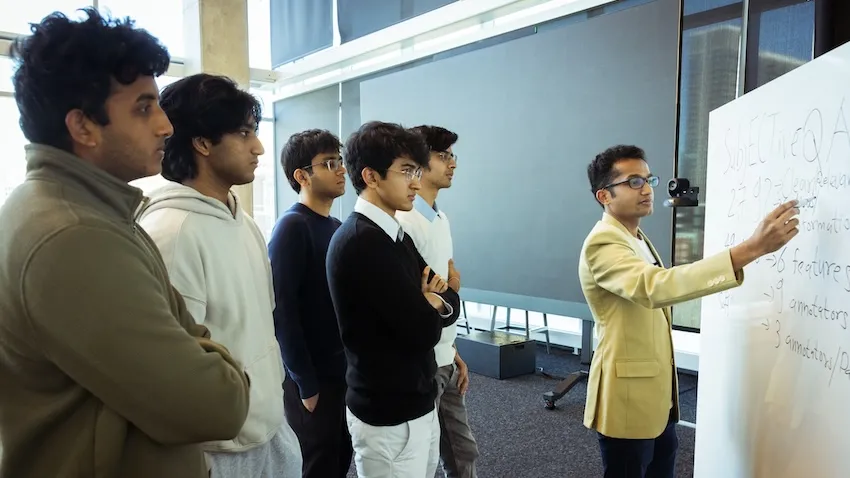

SubjECTive-QA culminated from two semesters of work through Georgia Tech’s Vertically Integrated Projects (VIP) Program. The VIP Program is an approach to higher education where undergraduate and graduate students work together on long-term project teams led by faculty.

Undergraduate students earn academic credit and receive hands-on experience through VIP projects. The extra help advances ongoing research and gives graduate students mentorship experience.

Computer science major Huzaifa Pardawala and mathematics major Siddhant Sukhani co-led the SubjECTive-QA project with Shah.

Fellow collaborators included Veer Kejriwal, Abhishek Pillai, Rohan Bhasin, Andrew DiBiasio, Tarun Mandapati, and Dhruv Adha. All six researchers are undergraduate students studying computer science.

Sudheer Chava co-advises Shah and is the faculty lead of SubjECTive-QA. Chava is a professor in the Scheller College of Business and director of the M.S. in Quantitative and Computational Finance (QCF) program.

Chava is also an adjunct faculty member in the College of Computing’s School of Computational Science and Engineering (CSE).

"Leading undergraduate students through the VIP Program taught me the powerful impact of balancing freedom with guidance,” Shah said.

“Allowing students to take the helm not only fosters their leadership skills but also enhances my own approach to mentoring, thus creating a mutually enriching educational experience.”

Presenting SubjECTive-QA at NeurIPS 2024 exposes the dataset for further use and refinement. NeurIPS is one of three primary international conferences on high-impact research in AI and ML. The conference occurs Dec. 10-15.

The SubjECTive-QA team is among the 162 Georgia Tech researchers presenting over 80 papers at NeurIPS 2024. The Georgia Tech contingent includes 46 faculty members, like Chava. These faculty represent Georgia Tech’s Colleges of Business, Computing, Engineering, and Sciences, underscoring the pertinence of AI research across domains.

"Presenting SubjECTive-QA at prestigious venues like NeurIPS propels our research into the spotlight, drawing the attention of key players in finance and tech,” Shah said.

“The feedback we receive from this community of experts validates our approach and opens new avenues for future innovation, setting the stage for transformative applications in industry and academia.”

News Contact

Bryant Wine, Communications Officer

bryant.wine@cc.gatech.edu

Dec. 04, 2024

A new machine learning (ML) model from Georgia Tech could protect communities from diseases, better manage electricity consumption in cities, and promote business growth, all at the same time.

Researchers from the School of Computational Science and Engineering (CSE) created the Large Pre-Trained Time-Series Model (LPTM) framework. LPTM is a single foundational model that completes forecasting tasks across a broad range of domains.

Along with performing as well or better than models purpose-built for their applications, LPTM requires 40% less data and 50% less training time than current baselines. In some cases, LPTM can be deployed without any training data.

The key to LPTM is that it is pre-trained on datasets from different industries like healthcare, transportation, and energy. The Georgia Tech group created an adaptive segmentation module to make effective use of these vastly different datasets.

The Georgia Tech researchers will present LPTM in Vancouver, British Columbia, Canada, at the 2024 Conference on Neural Information Processing Systems (NeurIPS 2024). NeurIPS is one of the world’s most prestigious conferences on artificial intelligence (AI) and ML research.

“The foundational model paradigm started with text and image, but people haven’t explored time-series tasks yet because those were considered too diverse across domains,” said B. Aditya Prakash, one of LPTM’s developers.

“Our work is a pioneer in this new area of exploration where only few attempts have been made so far.”

[MICROSITE: Georgia Tech at NeurIPS 2024]

Foundational models are trained with data from different fields, making them powerful tools when assigned tasks. Foundational models drive GPT, DALL-E, and other popular generative AI platforms used today. LPTM is different though because it is geared toward time-series, not text and image generation.

The Georgia Tech researchers trained LPTM on data ranging from epidemics, macroeconomics, power consumption, traffic and transportation, stock markets, and human motion and behavioral datasets.

After training, the group pitted LPTM against 17 other models to make forecasts as close to nine real-case benchmarks. LPTM performed the best on five datasets and placed second on the other four.

The nine benchmarks contained data from real-world collections. These included the spread of influenza in the U.S. and Japan, electricity, traffic, and taxi demand in New York, and financial markets.

The competitor models were purpose-built for their fields. While each model performed well on one or two benchmarks closest to its designed purpose, the models ranked in the middle or bottom on others.

In another experiment, the Georgia Tech group tested LPTM against seven baseline models on the same nine benchmarks in zero-shot forecasting tasks. Zero-shot means the model is used out of the box and not given any specific guidance during training. LPTM outperformed every model across all benchmarks in this trial.

LPTM performed consistently as a top-runner on all nine benchmarks, demonstrating the model’s potential to achieve superior forecasting results across multiple applications with less and resources.

“Our model also goes beyond forecasting and helps accomplish other tasks,” said Prakash, an associate professor in the School of CSE.

“Classification is a useful time-series task that allows us to understand the nature of the time-series and label whether that time-series is something we understand or is new.”

One reason traditional models are custom-built to their purpose is that fields differ in reporting frequency and trends.

For example, epidemic data is often reported weekly and goes through seasonal peaks with occasional outbreaks. Economic data is captured quarterly and typically remains consistent and monotone over time.

LPTM’s adaptive segmentation module allows it to overcome these timing differences across datasets. When LPTM receives a dataset, the module breaks data into segments of different sizes. Then, it scores all possible ways to segment data and chooses the easiest segment from which to learn useful patterns.

LPTM’s performance, enhanced through the innovation of adaptive segmentation, earned the model acceptance to NeurIPS 2024 for presentation. NeurIPS is one of three primary international conferences on high-impact research in AI and ML. NeurIPS 2024 occurs Dec. 10-15.

Ph.D. student Harshavardhan Kamarthi partnered with Prakash, his advisor, on LPTM. The duo are among the 162 Georgia Tech researchers presenting over 80 papers at the conference.

Prakash is one of 46 Georgia Tech faculty with research accepted at NeurIPS 2024. Nine School of CSE faculty members, nearly one-third of the body, are authors or co-authors of 17 papers accepted at the conference.

Along with sharing their research at NeurIPS 2024, Prakash and Kamarthi released an open-source library of foundational time-series modules that data scientists can use in their applications.

“Given the interest in AI from all walks of life, including business, social, and research and development sectors, a lot of work has been done and thousands of strong papers are submitted to the main AI conferences,” Prakash said.

“Acceptance of our paper speaks to the quality of the work and its potential to advance foundational methodology, and we hope to share that with a larger audience.”

News Contact

Bryant Wine, Communications Officer

bryant.wine@cc.gatech.edu

Dec. 03, 2024

Tequila A.L. Harris, a professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech, leads energy and manufacturing initiatives at the Strategic Energy Institute. Her research explores the connectivity between the functionality of nano- to macro-level films, components, and systems based on their manufacture or design and their life expectancy, elucidating mechanisms by which performance or durability can be predicted. She uses both simulations and experimentation to better understand this connectivity.

By addressing complex, fundamental problems, Harris aims to make an impact on many industries, in particular energy (e.g., polymer electrolyte membrane fuel cells), flexible electronics (e.g., organic electronics), and clean energy (e.g., water), among others.

Harris has experience in developing systematic design and manufacturing methodologies for complex systems that directly involve material characterization, tooling design and analysis, computational and analytical modeling, experimentation, and system design and optimization. Currently, her research projects focus on investigating the fundamental science associated with fluid transport, materials processing, and design issues for energy/electronic/environmental systems. Below is a brief Q&A with Harris, where she discusses her research and how it influences the energy and manufacturing initiatives at Georgia Tech.

- What is your field of expertise and at what point in your life did you first become interested in this area?

In graduate school, I aimed to become a roboticist but shifted my focus after realizing I was not passionate about coding. This led me to explore manufacturing, particularly scaled manufacturing processes that transform fluids into thin films for applications in energy systems. Subsequently, my expertise is in coating science and technology and manufacturing system development.

- What questions or challenges sparked your current energy research? What are the big issues facing your research area right now?

We often ask how we can process materials more cost-effectively and create complex architectures that surpass current capabilities. In energy systems, particularly with fuel cells, reducing the number of manufacturing steps is crucial, as each additional step increases costs and complexity. As researchers, we focus on understanding the implications of minimizing these steps and how they affect the properties and performance of the final devices. My group studies these relationships to find innovative manufacturing solutions. A major challenge in the manufacture of materials lies in scaling efficiently while maintaining performance and keeping costs low enough for commercial adoption. This is a pressing issue, especially for enabling technologies such as batteries, fuel cells, and flexible electronics needed for electric vehicles, where the production volumes are on the order of billions per year.

- What interests you the most in leading the research initiative on energy and manufacturing? Why is your initiative important to the development of Georgia Tech’s energy research strategy?

What interests me most is the inherent possibility of advancing energy technologies holistically, from materials sourcing and materials production to public policy. More specifically, my interests are in understanding how we can scale the manufacture of burgeoning technologies for a variety of areas (energy, food, pharmaceuticals, packaging, and flexible electronics, among others) while reducing cost and increasing production yield. In this regard, we aim to incorporate artificial intelligence and machine learning in addition to considering limitations surrounding the production lifecycle. The challenges that exist to meet these goals cannot be done in a silo but rather as part of interdisciplinary teams who converge on specific problems. Georgia Tech is uniquely positioned to make significant impacts in the energy and manufacturing ecosystem, thanks to our robust infrastructure and expertise. With many manufacturers relocating to Georgia, particularly in the "energy belt" for EVs, batteries, and recycling facilities, Georgia Tech can serve as a crucial partner in advancing these industries and their technologies.

- What are the broader global and social benefits of the research you and your team conduct on energy and manufacturing?

The global impact of advancing manufacturing technologies is significant for processing at relevant economy of scales. To meet such demands, we cannot always rely on existing manufacturing know-how. The Harris group holds the intellectual property on innovative processes that allow for the faster fabrication of individual or multiple materials, and that exhibit higher yields and improved performance than existing methods. Improvements in manufacturing systems often result in reduced waste, which is beneficial to the overall materials development ecosystem. Another global and societal benefit is workforce development. The students on my team are well-trained in the manufacture of materials using tools that are amenable to the most advanced and scalable manufacturing platform, roll-to-roll manufacturing, with integrated coating and printing tools. This unique skill set equips our students to thrive and become leaders in their careers.

- What are your plans for engaging a wider Georgia Tech faculty pool with the broader energy community?

By leveraging the new modular pilot-scale roll-to-roll manufacturing facility that integrates slot die coating, gravure/flexography printing, and inkjet printing, I plan to continue reaching out to faculty and industrial partners to find avenues for us to collaborate on a variety of interdisciplinary projects. The goal is to create groups that can help us advance materials development more rapidly by working as a collective from the beginning, versus considering scalable manufacturing pathways as an afterthought. By bringing interdisciplinary groups (chemists, materials scientists, engineers, etc.) together early, we can more efficiently and effectively overcome traditional delays in getting materials to market or, worse, the inability to push materials to market (which is commonly known as the valley of death). This can only be achieved by dismantling barriers that hinder early collaboration. This new facility aims to foster collaborative work among stakeholders, promoting the integrated development and characterization of various materials systems and technologies, and ultimately leading to more efficient manufacturing practices.

- What are your hobbies?

I enjoy cooking and exploring my creativity in this space by combining national and international ingredients to make interesting and often delicious fusion cuisines. I also enjoy roller skating, cycling, and watching movies with my family and friends.

- Who has influenced you the most?

From a professional standpoint, my research team influences me the most. After I present them with a problem, they are encouraged and expected to think beyond our initial starting point. This ability to freely think and conceive of novel solutions sparks many new ideas on which to build future ideas. The best cases have kept me up at night, inspiring me to think about how to approach new problems and funding opportunities. I carry their experiences and challenges with me. Their influence on me is profound and is fundamentally why I am a professor.

News Contact

Priya Devarajan || SEI Communications Program Manager

Dec. 02, 2024

In the dynamic world of supply chain and logistics, talent development has emerged as a critical differentiator for organizations seeking to stay competitive. As businesses navigate the complexities of global supply chains, disruptive technologies, and shifting market demands, having a skilled and adaptable workforce isn’t just an advantage—it’s a necessity. Moreover, investing in talent development isn’t only about building capability; it’s also a proven strategy for attracting and retaining top talent in a competitive job market.

At the Georgia Tech Supply Chain and Logistics Institute (SCL) and Georgia Tech Professional Education (GTPE), we understand the challenges organizations face in developing their teams. Whether you’re managing a workforce with a mix of new hires and seasoned professionals, undergoing a major organizational transformation, or striving to stay ahead, talent development must remain at the forefront of your strategy.

Why Organizations Choose Georgia Tech

Organizations turn to us for talent development solutions for several reasons:

A Balance of New and Experienced Professionals: Managing talent means addressing the needs of both emerging professionals who bring fresh energy and experienced workers who provide deep institutional knowledge. Our programs cater to this balance, offering foundational courses for newcomers and advanced training for seasoned leaders.

A Competitive Edge in Attraction and Retention: Offering world-class development opportunities signals to current and prospective employees that your organization values growth. This commitment is especially critical in today’s job market, where career development ranks high on employees’ priorities.

Practical, Immediately Applicable Training: Adult learners need training that works in tandem with their day-to-day responsibilities. Our modular programs are designed for immediate real-world application, ensuring learning outcomes translate directly into workplace improvements.

Scalable Solutions for All Organizations: For growing companies, introducing structure and formal training is often the next step in their evolution. For larger enterprises, we complement internal training programs with flexible, impactful learning options that align with organizational goals.

What Makes Our Offerings Unique

We deliver training solutions tailored to the realities of today’s supply chain and logistics landscape, setting us apart in the industry. Here’s how:

Flexible Delivery Options: From self-paced courses to live and virtual classes, public programs, and custom corporate training, we offer a variety of formats to meet your needs. For example, our hybrid Engineering the Warehouse course combines online lectures with in-person lab sessions to maximize convenience and impact.

Bite-Sized, Modular Learning: Our modular approach allows professionals to access content in manageable segments, enabling learning alongside work demands. For instance, our series on supply chain analytics is broken into short, focused modules that let learners immediately apply concepts like inventory optimization and demand forecasting.

Innovative and Relevant Content: We stay ahead of the curve by addressing emerging industry trends. Our new course on Generative AI in Supply Chain equips professionals to leverage advanced technologies for process optimization and strategic planning.

Industry-Informed Solutions: Collaboration with industry leaders ensures our content addresses real-world challenges. For example, our program on Supply Chain Risk and Resilience integrates insights from Fortune 500 companies to help businesses mitigate disruptions effectively.

Grounded in Research: Every program is informed by leading academic research and designed to reflect the best practices of adult learning, ensuring your team gains knowledge that is both current and actionable.

Preparing for 2025: A Competitive Advantage

As we approach 2025, talent development remains central to addressing the challenges of the supply chain industry. Large enterprises continue to seek solutions to skill gaps and organizational transformation, while small and mid-sized organizations increasingly recognize the need for formalized training. Georgia Tech’s offerings serve as a vital resource, ensuring professionals stay competitive, skilled, and current in an ever-evolving landscape.

Investing in your workforce today not only ensures your organization’s readiness for tomorrow’s challenges but also signals a commitment to your team’s growth and success. At Georgia Tech, we are proud to partner with companies of all sizes, providing a unique blend of flexibility, innovation, and industry relevance that drives results.

Whether you need a program to supplement your internal training, build a comprehensive development strategy, or prepare your team for the future, we’re here to help. Contact us at info@scl.gatech.edu to learn more about how we can support your talent development needs.

Let’s work together to ensure your supply chain workforce is ready to lead in 2025 and beyond.